Why Monitor Sewage Treatment Plant MLSS?

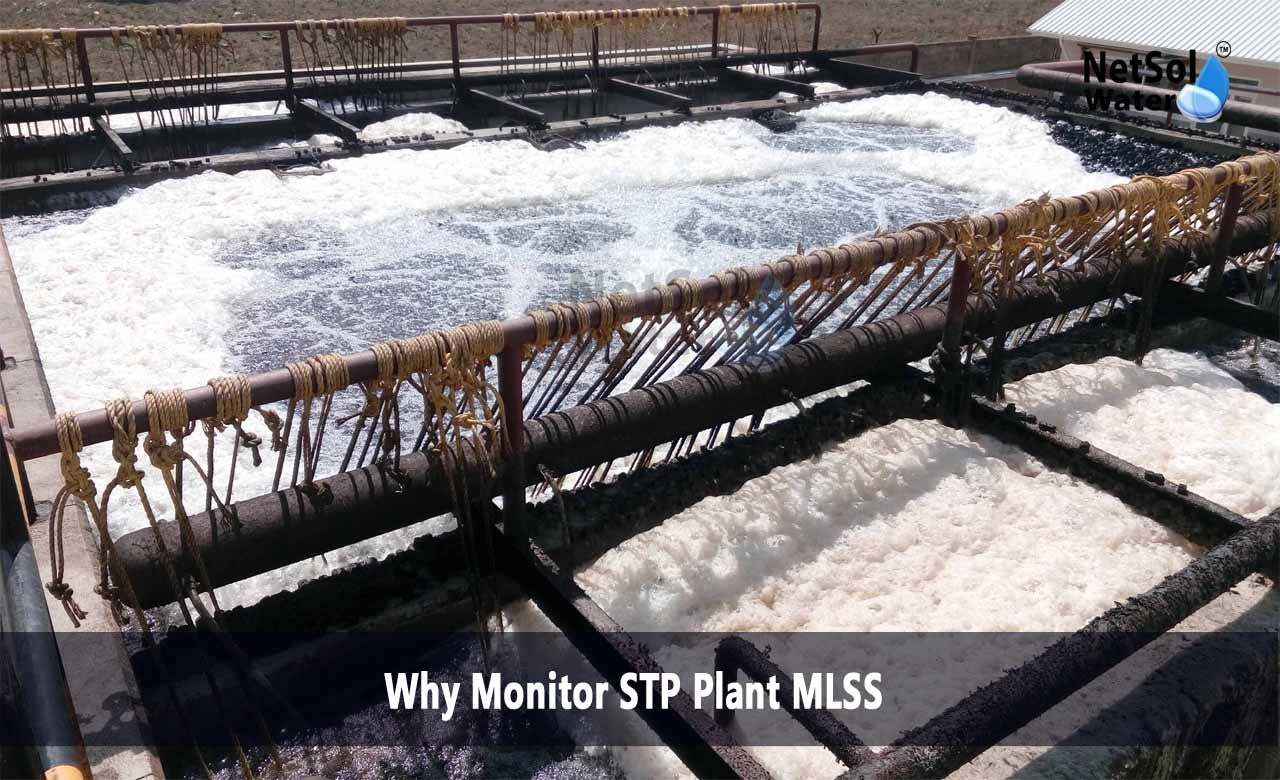

Sewage Treatment Plants are essential for the treatment of wastewater before it is released into the environment. Mixed Liquor Suspended Solids (MLSS) is one of the most important parameters to be monitored for measuring the efficiency of an STP. MLSS is the amount of suspended solids, such as microorganisms, present in the aeration tank that is accountable for the breakdown of organic content. Monitoring MLSS is necessary for ensuring process stability and the best treatment outcomes.

Importance of Monitoring MLSS

Monitoring MLSS is essential because it directly influences the biological treatment process within STPs. The right balance of MLSS guarantees the following:

· Efficient microbial activity: Proper MLSS levels support the growth and performance of beneficial microorganisms responsible for organic matter degradation.

· Compliance with environmental regulations: Discharge from STPs must meet stringent pollution control norms, which depend on maintaining the correct MLSS concentration.

· Prevention of operational issues: Uncontrolled MLSS levels can lead to inefficiencies, increased energy consumption, and process failures, all of which can impact plant performance.

Failure to monitor and manage MLSS levels effectively can result in poor treatment efficiency, increased sludge production, system imbalances, and ultimately environmental pollution.

Key Reasons to Monitor MLSS

· Achieves Biological Stability: MLSS achieves a balanced setting for microorganisms to operate properly. Low levels of MLSS may decrease the efficiency of the treatment, and high levels result in system overload and sludge bulking.

· Enhances Effluent Quality: Appropriate MLSS ensures high-quality effluent through breakdown of organic and inorganic components, avoiding excessive turbidity and suspended solids within the released water.

· Prevents System Imbalance: Regular MLSS monitoring helps operators adjust aeration rates, sludge wasting, and return sludge flow to maintain system equilibrium and prevent process failures.

· Optimizes Oxygen Utilization: Aeration is a significant energy-consuming process in STPs. Controlling MLSS ensures efficient oxygen transfer, reducing energy consumption and operational costs.

· Improves Sludge Settling: Optimal MLSS range enhances sludge settling properties in the secondary clarifier, minimizing sludge carryover and providing clear treated water.

· Facilitates Regulatory Compliance: STPs are required to comply with environmental discharge regulations. Effective MLSS monitoring guarantees compliance with regulations through effective treatment performance.

Methods for Monitoring MLSS

To maintain effective MLSS levels, STPs must implement proper monitoring methods. Below are some key ways to measure and control MLSS:

Periodic Sampling

Operators should collect MLSS samples from the aeration tank at regular intervals for analysis. Sampling at different times of the day helps in understanding MLSS variations and enables timely corrective actions.

Laboratory Analysis

Standard lab procedures are used to measure MLSS concentration. Laboratory analysis provides accurate data that helps in determining whether MLSS levels need to be adjusted. Comparing results with recommended MLSS levels allows operators to make informed decisions regarding sludge wasting and aeration control.

Online Sensors

Advanced STPs use automated MLSS sensors for real-time monitoring. These sensors continuously measure MLSS levels and send data to the control system. Real-time monitoring allows operators to detect fluctuations immediately and take corrective actions, reducing the chances of process failures.

Parameter Adjustment

Once MLSS levels are analyzed, adjustments in aeration rates, return sludge flow, and sludge wasting must be made. Keeping a close eye on MLSS trends allows operators to prevent potential problems before they escalate.

Best Practices for MLSS Monitoring

To ensure optimal MLSS management, STP operators should follow these best practices:

· Monitor MLSS consistently: Regular testing and tracking help identify trends and make proactive adjustments.

· Optimize sludge wasting: Proper sludge wasting maintains MLSS within the desired range, preventing sludge build-up and treatment inefficiencies.

· Use real-time sensors where possible: Automated sensors provide immediate feedback, allowing quick corrective measures.

· Ensure proper aeration control: Adjusting aeration levels based on MLSS readings prevents excessive energy use and supports microbial activity.

· Train operators: Well-trained personnel can interpret MLSS data effectively and respond to deviations promptly.

Conclusion

Monitoring MLSS for an STP is importantfor ensuring process efficiency, compliance, and optimal operational costs. Through constant monitoring of MLSS levels and the corresponding adjustments, plant operators can ensure stable biological treatment and good-quality effluent discharge. Successful MLSS management ultimately translates into a more sustainable and reliable wastewater treatment process with less risk of environmental contamination and process failure. The adoption of best practices for MLSS monitoring not only maximizes plant performance but also long-term cost benefits and regulatory compliance.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com