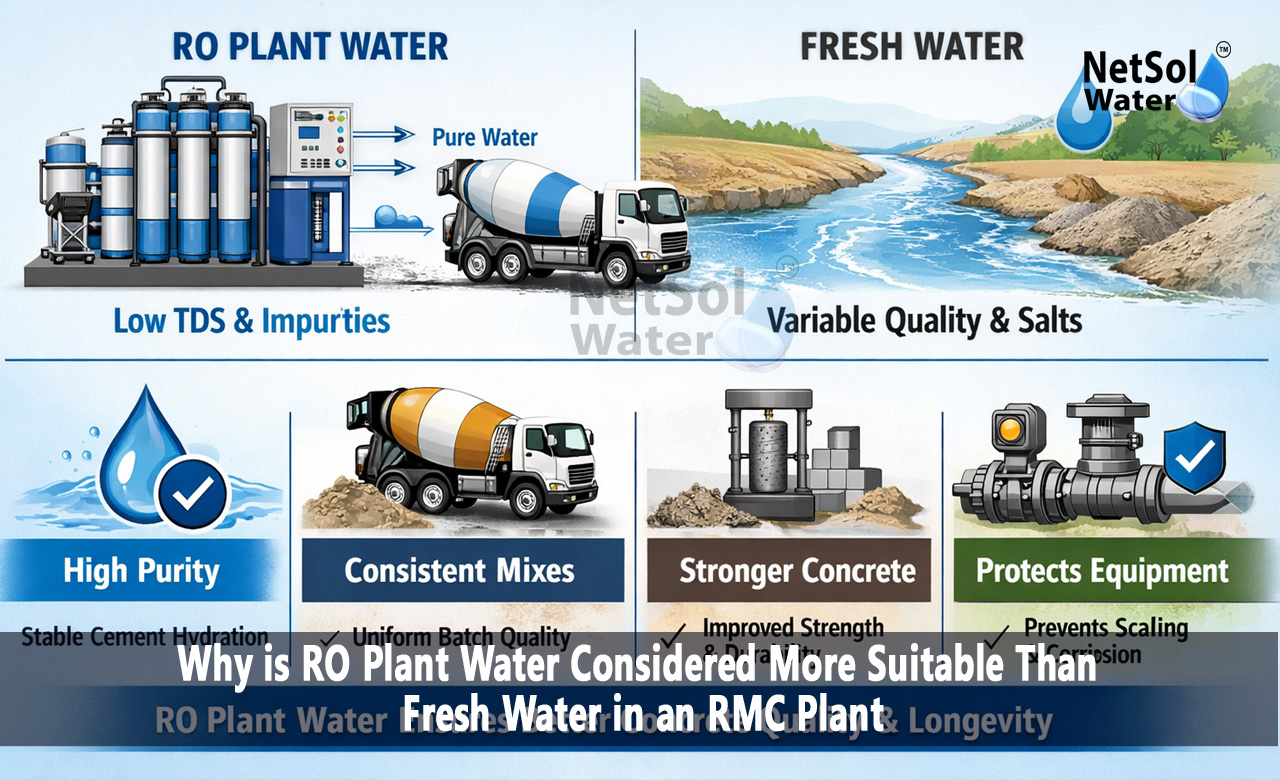

Why RO Water Is Better Than Fresh Water in RMC Plants?

Water makes up a large part of concrete. Ready mix concrete plants need water that keeps mixes steady and free from surprise changes. Water controls workability, strength and curing. When an RMC plant uses water that varies in salts and particles, the mix can change from batch to batch. That change can harm the final product and slow down work at the job site. For this reason many plants move to treated water and especially to water from an Reverse Osmosis plant supplied by a Commercial RO Plant Manufacturer. RO plant water has low dissolved solids and low unwanted ions. It also has few organic traces and no suspended dirt. These traits help make the concrete mix uniform and predictable.Here we will explain why RO plant water is considered more suitable than fresh water in an RMC plant.

Purity and Chemical Balance

Water purity affects chemistry of cement and concrete. Clean water helps cement binders hydrate in a steady way. When water has salts or acids the hydration path can change and the final strength can shift.

1: Dissolved solids and ions

Dissolved salts change the water cement reaction. Sulfate and chloride can speed up or slow down setting. Chloride can also harm steel in reinforced concrete. Fresh water from wells or rivers can have these ions in varying amounts. Reverse Osmosis plant water has a very low total dissolved solids level and low ionic load. That low ion count keeps the hydration reaction steady and helps reduce risk of corrosion in steel.

2: Alkalinity and pH control

High alkalinity or sudden pH shifts change how admixtures perform. Admixtures like plasticizers can work less well when pH moves. Reverse Osmosis plant water offers a more neutral and stable pH. Stable pH helps admixtures deliver expected slump and strength results. The process reduces the need for trial and error when a new water source arrives.

3: Organic matter and suspended particles

Organic matter can affect air entrainment and cause unpredictable foam and bubbles. Suspended particles can demand more cement paste and thus change strength. RO plant water has low organics and no suspended solids. That clarity helps produce cleaner mixes and reduces the risk of unwanted changes in the microstructure of concrete.

Consistency and Quality Control

Consistency drives quality in an RMC plant. When each truck leaves the plant it should match the mix design and the target performance. Let us have a look on methods and results that use Reverse Osmosis water to keep quality high.

1: Batch-to-batch uniformity

When water quality shifts the same mix design can give different slumps and different compressive strengths. An RO plant provides near constant water quality day and night. This steady input makes process control simpler and reduces variation in finished concrete. Plants can reduce waste and cut rework when they keep water consistent.

2: Easier testing and calibration

Quality teams test water for TDS, chlorides and other markers. When the water is stable these test results need less frequent action. Teams can set clear calibration values for mix design and meters. RO plant water reduces the number of surprise test failures. That in turn reduces the time spent on adjustments during busy hours.

3: Better control of admixture performance

Admixtures respond to water quality. When water changes a superplasticizer can give a different slump or set profile. With RO plant water the plant can predict how an admixture will behave. The team can dose admixtures with more confidence. This lowers the chance of underdosing or overdosing and improves product repeatability.

Workability and Strength of Concrete

Workability and strength are the core performance traits of concrete. Water type influences both traits from the first mix to long term cure. Let us have a look on how RO plant water supports better workability and strength.

1: Predictable slump retention

Concrete needs to travel from plant to site and then place and finish. Slump retention matters for ease of placing and for surface finish quality. RO plant water reduces the chemical actors that accelerate slump loss. That helps the concrete keep its workability for longer during transit and placement.

2: Strength gain and long term performance

Impurities can interfere with cement hydration or create weak zones in the matrix. Clean water helps hydration run as planned and improves interparticle bonding. Over time this helps the concrete reach designed compressive values. Using RO plant water helps to avoid uneven strength development and reduces hidden strength losses that show up when cores are cut months after casting.

3: Reduced risk of efflorescence and stains

Soluble salts in fresh water can move to the surface during curing and form white deposits. That effect harms appearance and can indicate deeper moisture paths. RO plant water has fewer soluble salts and thus lowers the chance of efflorescence. Fewer surface marks improve aesthetics and reduce extra cleaning on site.

Durability of Equipment and Pipes

Water quality does not only affect concrete. It also affects the plant equipment and the life of pipes and pumps. Let us have a look on how RO plant water reduces wear and protects plant assets.

1: Scale and deposits in pipes

Hard water with high mineral content forms scale in pumps, pipes and valves. That scale reduces flow and raises energy use. RO plant water has low hardness and low mineral content. It reduces scale formation and keeps flow paths clean for longer. This lowers maintenance time and reduces unplanned downtime.

2: Corrosion and metal wear

Certain ions in fresh water increase the risk of corrosion in metal parts. Corrosion shortens pump life and can cause leaks. RO plant water cuts the ionic load that speeds corrosion. That protection helps pumps and mixers run longer with fewer breakdowns and with fewer parts to replace.

3: Longer life for sensors and seals

Many sensors depend on clean surfaces. Solids and salts can clog or foul sensors and seals. This leads to poor readings and to extra calibration tasks. RO plant water keeps sensors cleaner and extends the useful life of seals. The plant can run more reliably and with fewer interruptions.

Health and Environmental Safety

Safe water supports safe work and less environmental harm.Let us have a look on health and environmental gains when an RMC plant uses RO plant water.

1: Lower risk of biological growth

Fresh water can carry bacteria and algae that grow in storage tanks. These organisms can form slime that blocks pipework and that interferes with dosing systems. RO plant water removes most organisms and reduces risk of blooms in tanks. That lowers the need for frequent tank cleaning and for strong biocides.

2: Safer handling for staff

Cleaner water means fewer surprises when workers handle admixtures and slurries. The team can avoid certain reactions that happen with contaminated water. That reduces health hazards and improves daily plant safety.

3: Reduced environmental discharge problems

Waste water from washout can contain salts and suspended solids. If the input water has high dissolved salts the wash water becomes harder to treat or dispose of. Using RO plant water reduces the salt load in waste streams and helps the plant meet discharge standards. That leads to less environmental risk and to fewer penalties.

Cost and Operational Efficiency

Cost matters every day at an RMC plant. Spending on raw water treatment and on maintenance affects the bottom line.

1: Less rework and fewer rejected batches

When concrete stays within spec, the plant reduces wasted material and time. RO plant water supports repeatable mixes and lowers the number of batches that fail tests. Fewer rejected loads mean lower material costs and higher customer satisfaction.

2: Lower maintenance cost

Scale and corrosion raise cost for spare parts and labour. RO plant water eases these issues and cuts the frequency of repairs. That reduces direct maintenance spend and reduces the indirect cost of lost production. Over time these savings can cover the cost of water treatment.

3: Predictable operational planning

When water quality varies, the plant must plan for extra tests and for flexible dosing. That need creates extra steps and labour hours. RO plant water reduces these surprises and lets the plant schedule tasks more reliably. Predictable work brings steady output and helps fulfil contracts on time.

Implementation Considerations

Moving to RO plant water needs planning and care. Let us have a look on the key steps that make the change smooth and effective.

1: System sizing and storage

A plant must size the RO plant to match peak demand. Undersized systems cause delays and force the plant to use backup fresh water. Oversized systems waste capital and space. Proper sizing and pressure balancing deliver steady supply. Large storage helps buffer peaks and makes transport to the mixers easier.

2: Pre-treatment and maintenance

RO plants need pre-treatment like filtration and chemical dosing to protect membranes. The plant must set a simple maintenance plan and a testing schedule. Regular membrane checks and periodic cleaning keep the system working well and reduce downtime.

3: Monitoring and quality checks

After installation the plant must test water regularly for TDS ions and microbiological load. Using simple checks and clear acceptance limits makes quality control straightforward. A stable reporting routine helps the plant catch issues early and keep the production lines moving.

Conclusion

RO plant water is considered more suitable than fresh water in an RMC plant for many clear reasons. Clean water improves mix uniformity and helps admixtures work as designed. Clean water reduces scale and corrosion and it protects pumps pipes and sensors. Clean water lowers biological risk and it helps with discharge and environmental rules. Clean water also cuts rework and saves maintenance cost. These combined effects support better concrete performance and they help the plant run with more predictability. If you want to learn more about how to set up RO plant water at your RMC plant or if you need a practical plan for sizing and running a system please get in touch. Request a consultation and an expert can review your needs and propose a workable solution.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com