Why is OrganoClay used in Waste Water Treatment Plant?

Organoclay is commonly used in the upstream sector of the petroleum industry for removing hydrocarbons from refinery process water when used for water treatment, but it is rarely used in the production of petroleum. Many other industries, such as shipping and dockside servicing, car washes, and other businesses that deal with an oily wastewater stream, use organoclay. Organoclays have also been tested for the removal of other organic chemicals from ground and surface water, such as PCBs and pesticides.

Organoclay is a low-cost filtration media

When used alone, Organoclay removes oil at 700% the rate of activated carbon and cuts operating costs by 50% or more. When used as a pre-treatment for activated carbon in oil and grease removal applications, Organoclay effectively removes the oil and grease, allowing the activated carbon to remove the soluble organic compounds more efficiently.

The use of Organoclay improves the efficiency of the treatment process

The quaternary amine-treated clay pellets can absorb 50–60% of their weight in oil, grease, and other low solubility organic compounds. Organoclay improves overall system performance and lowers costs when used upstream of activated carbon or downstream of other oil removal processes.

Organoclay can be used to pre-treat the influent of GAC filters, reverse osmosis units, ultra filtration units, and other systems where less soluble, higher molecular weight hydrocarbons cause plugging, fouling, and equipment contamination.

The amount of Organoclay needed depends on the contaminant concentration and type, contact time, and fluid temperature. Contaminants with lower concentrations and solubilities, longer contact times, and moderate fluid temperatures are generally preferred.

Hydrocarbon Removal with Organoclay

OrganoClays remove free hydrocarbons from wastewater as well as dissolved hydrocarbons such as benzene, toluene, ethylbenzene, and xylene. Modified Clay Media, when used in conjunction with a polishing stage of granular activated carbon, removes dissolved and free hydrocarbons to levels well below current water quality standards.

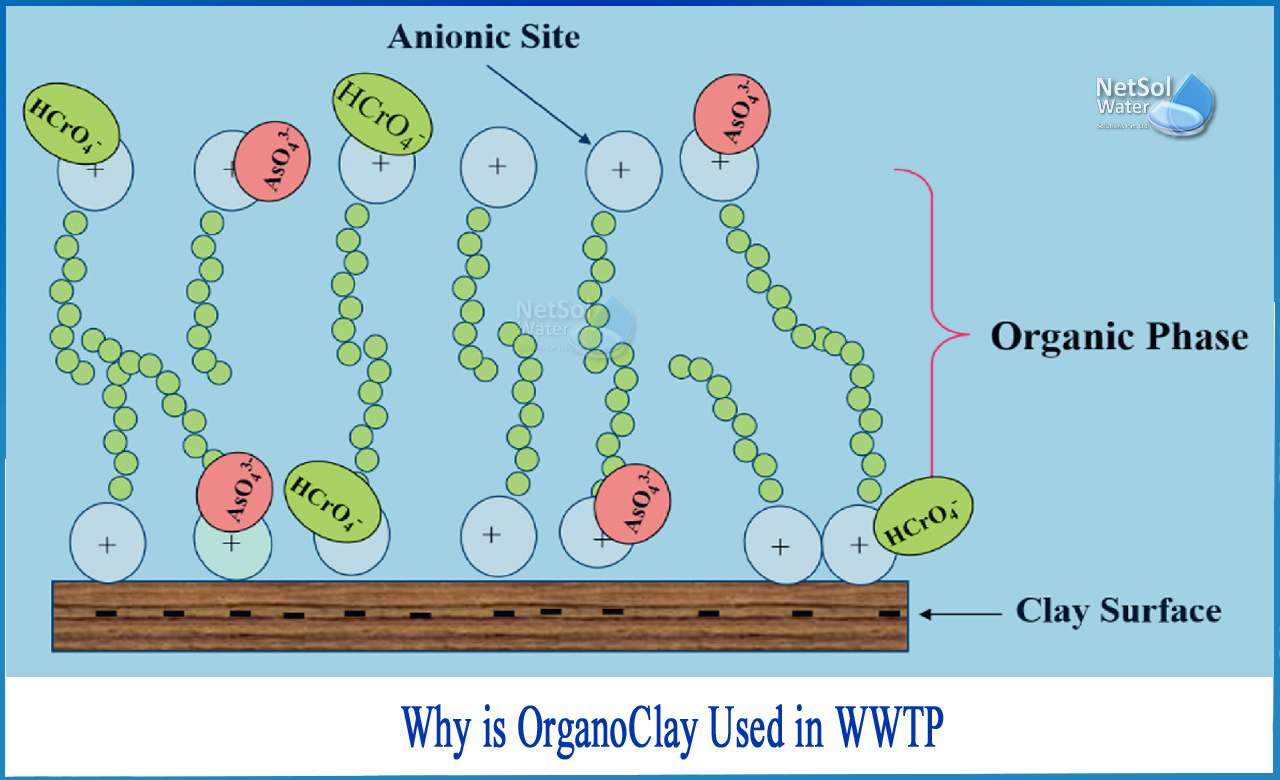

Organoclay products can be used to effectively remove oil and other hydrocarbons from water where traditional oil-water separators have had limited success. The product does not absorb hydrocarbons, but rather adsorbs them, leaving no byproduct of the process. During the adsorption process, the quaternary amines form organic pillars between the clay platelets, increasing the interlamellar distance and facilitating the formation of a hydrocarbon partition.

Conclusion

Our highly trained, competent staff at Netsol Water has a wealth of knowledge that they apply to all tasks, from installations to maintenance and repairs. Throughout our many years of operation, we have gained experience that allows us to operate on a wide variety of systems.

Netsol Water, the top producer of all sorts of water treatment plants in India, supplies the best technology and, depending on client needs, may provide a permanent monitoring network to make septic tanks eco-friendly.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.