Why are defoamers used in Wastewater Treatment plants?

Wastewater Treatment consists of domestic wastewater and wastewater from industrial plants and is a process of removing pollutants. There are many processes used to remove these contaminants, including chemical, biological and physical. The resulting treated wastewater must be clean enough to be returned to the environment or reused to dispose of the remaining solid waste. Sewage can be treated in a variety of ways, one of which is the municipal sewage treatment facility. At this plant, wastewater goes through a variety of treatment stages, including pre-treatment, primary, secondary and tertiary treatment.

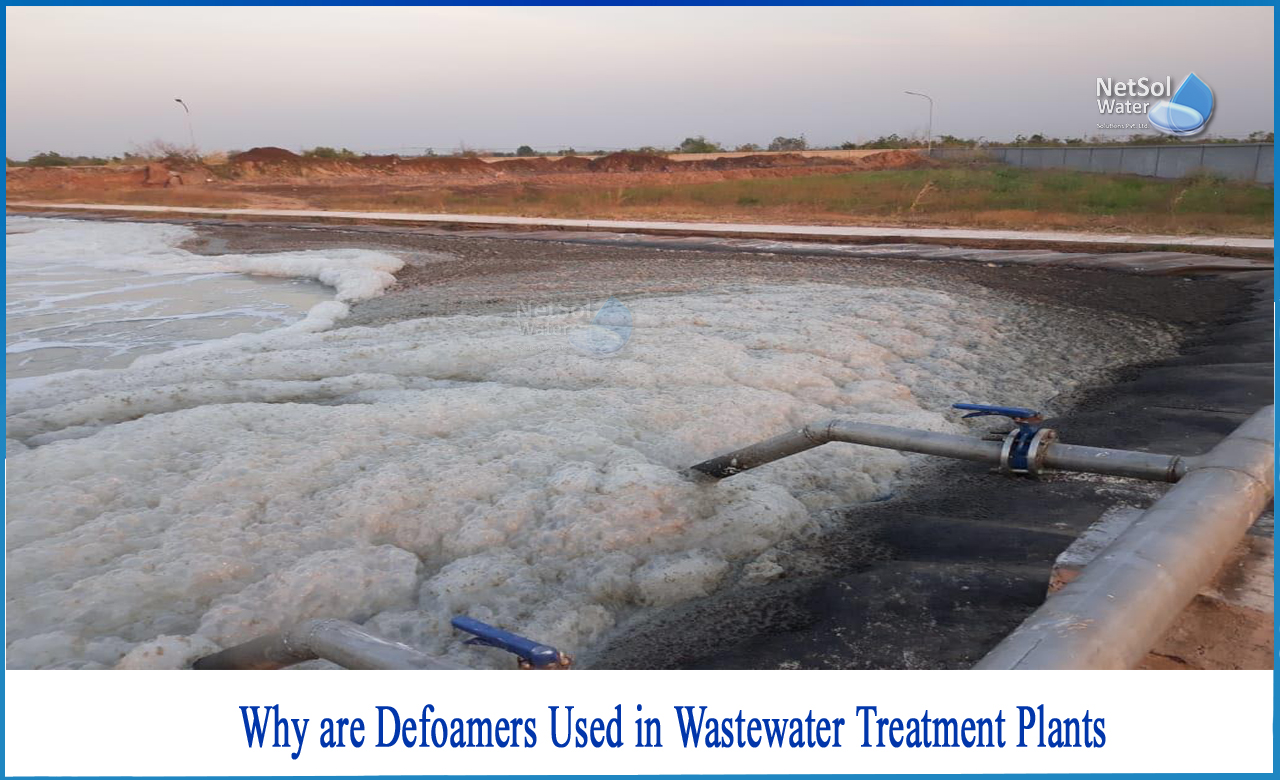

Issues with Foam generation

The causes of foam in sewage treatment plants are diverse and can be caused by chemical, biological or mechanical processes. In secondary treatment systems, bubbles are usually caused by biological activity. It can also be caused by mechanical impact, chemical contamination, surfactants in the influent, or some polymer treatments. Regardless of the cause, foaming and final wastewater in the secondary treatment area can lead to environmental, health and safety issues.

Too many bubbles in the aeration tank can cause many problems-

The foam layer can interfere with the oxygen uptake of microorganisms and prevent the breakdown of BOD. There are various de-foaming agents (esterified polysols, aqueous emulsions of fatty alcohols, and silicone-based products) to treat the foam in the oxygenation tank.

These defoamers are specially formulated so as not to affect dissolved oxygen levels. These defoamers are less toxic and highly biodegradable, so they have less environmental impact. For most applications, light foam is not an issue, but excessive foam or high density foam can often cause a variety of processing problems. These problems extend to erroneous readings from control and measurement devices (thermometers, levels and mass flow transmitters, etc.). Insufficient mixing of the reactants in the chemical process tank with the product stuck in the foam can also result in loss of production.

De-foamers are thus used to limit, reduce, prevent, or eliminate the formation of foam!

The Mechanism involved

The mechanism of many foam control products is to add hydrophobic hydrocarbons or silicone oils. These products act on detergent-induced and polysaccharide-induced foams caused by undernourishment. However, micro slick filament type bacteria has completely different properties and requires chemically different antifoaming agents. These filaments are hydrophobic and are usually present when high concentrations of FOG (fats, oils, greases) or fatty acids are present in significant concentrations. Hydrocarbons and silicone oils can actually exacerbate the problem. Glycol-based defoamers that do not contain mineral oil or silicone oil can be optimized for this type of microbial foam. Defoamers help break down the intertwined mass of filaments in the foam and disperse the filaments to speed up the washout.

Sewage problem

Sludge and scum bulking are two undesired, complex and unpredictable challenges for many wastewater treatment plants (WWTP). The filament causes bulking sludge tend to float, which can vary in depth, producing large amounts of foam. It can spread from the entire biological cycle to the anaerobic digestion tub and dehydration unit.

The traditional approach is to continuously inject the defoamer into the process at a normally tuned rate to treat the foam during peak demand. However, this amount is usually too high, as most systems produce little or no foam in most cases. Alternatively, chemicals are added unplanned, in very large quantities. In some cases, wastewater treatment plants can suffer for years without finding a sustainable solution to the problem. The chemicals used can also cause foaming problems, and the cost of the chemicals and the energy from unnecessary pumps can be important.

Defoaming Agents

The types of defoaming agents used in wastewater treatment systems range from silicone-based, mineral oil-based and polyalkylene glycol types. As mentioned earlier, hydrophobic defoamers can exacerbate the foaming problem of bacterial-based defoamers.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.