What is tube type heat exchanger and its component?

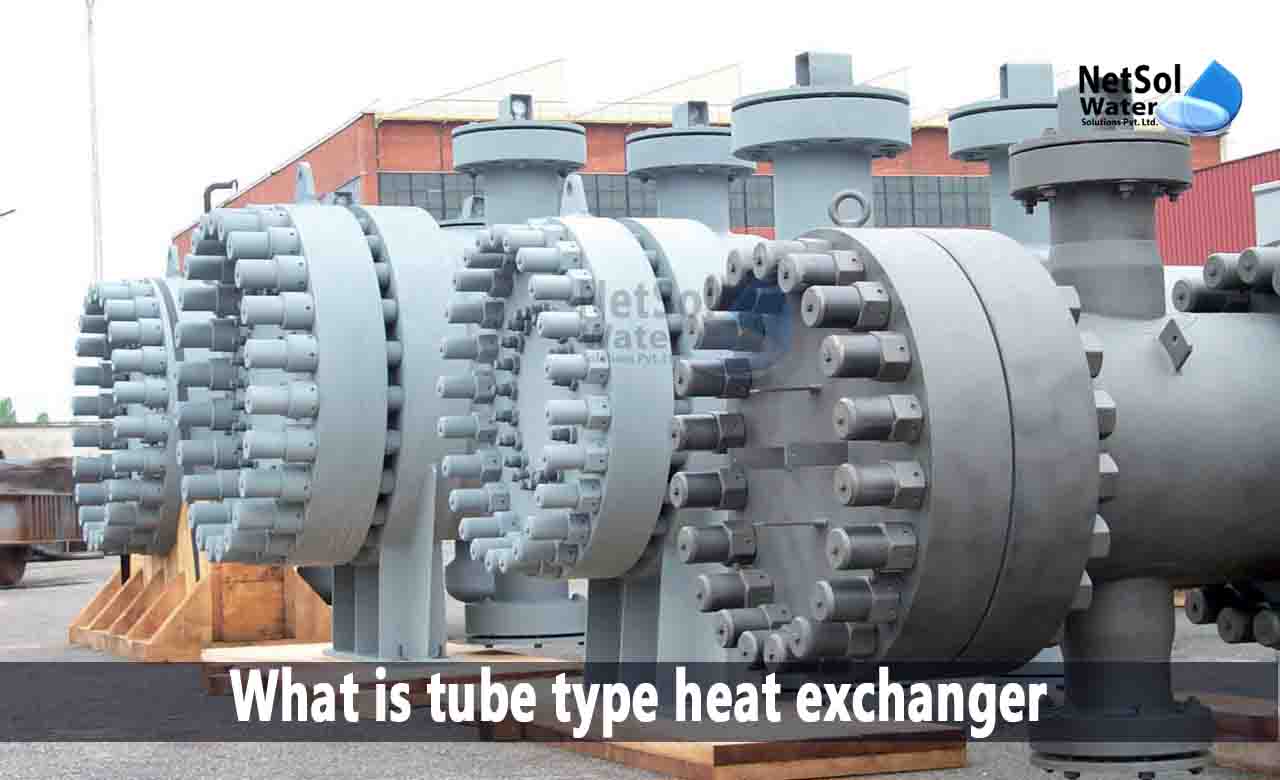

A tube heat exchanger is a type of heat exchanger that is made up of a large cylindrical enclosure, or shell, with bundles of perfectly spaced tubing compacted inside. The transfer of heat from one substance or medium to another is known as heat exchanging.

The most common type of heat exchange design is shell and tube heat exchangers. They are classified based on their properties, tubing type, and other features.

Components of Tube type Heat Exchanger

· Tubes

A tube heat exchanger has tubes that are welded or extruded from carbon steel, stainless steel, titanium, or copper. Compact heat exchangers have tube diameters of 0.625 inch (16mm), 0.75 inch (19mm), or one inch (25mm).

The thickness of the tubes is chosen for pressure, temperature, thermal stress, and corrosion resistance, at lengths ranging from 6 to 24 feet (2 meters to 7 meters). Longer tubes reduce shell diameter and result in a high shell pressure drop.

· Sheet Tube

The tube sheet is a perforated plate or sheet that is designed to support the tubes, on either end of the cylindrical shell. The shell extends beyond the tube sheets and is sealed on both ends, to form the enclosed chamber that the heads cover.

· Pitch of the Tube

The distance between the centers of two tubes is measured in tube pitch. Tubes are arranged in a triangular or square pattern, with the square pattern being the easiest to clean and producing the least turbulence.

Turbulent Flow in tube side

On the tube side, turbulent flow is required, which is accomplished by installing turbulators inside the tubes, through the holes in the tube sheet. Turbulence in the tubes, like turbulence in the shell, increases heat transfer capacity.

The turbulators' secondary function is to keep the inside of the tubes clean, and free of debris. Tubes have less turbulence and pressure drop, resulting in a more streamlined flow.

No. of Passes in tube type heat exchanger

Tube heat exchangers can have one, two, four, six, or eight passes, denoted by the letters 1-1, 1-2, 1-4, etc. The number of passes represents the number of times the fluid in the shell, passes through the fluid. The fluid only passes through the shell once in a single pass heat exchanger. The heat transfer coefficient increases as the number of passes increases.

Operation of tube type heat exchanger

The old fluid enters through the tube or shell inlet and is heated in the tubes, by conductive heating before exiting the process.

Turbulent flow in a shell and tube heat exchanger accelerates heat transfer, while preventing fouling in the tubes and shell walls. The constant turbulent flow self-cleans, ensuring continuous and optimum performance. Turbulence is created by baffles that direct the flow in the shell, while turbulators installed in the tubes create turbulation.

Thermal contact between the two fluids contained in the shell and tubes aids in the heat exchange process. One fluid evaporates cooler, while the other evaporates warmer or hotter.

Application of Tube Type heat exchanger

Tube heat exchangers are used in the food, beverage, dairy, and pharmaceutical industries, to ensure that their consumer products are safe, effective, and consistent.

Netsol Water provide a wide range of modern solutions, including water softener, wastewater treatment plants, sewage treatment plants, water treatment plants, RO Plants, and many more. Our clients can take advantage of these services. We also educate our clients on how to avoid pollution by taking a sustainable strategy, and utilizing advanced treatment methods and heat exchangers in WWTPs.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.