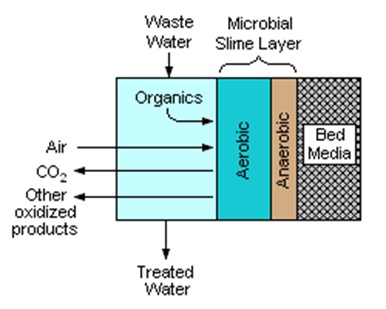

A fixed bed of extremely permeable media makes up a trickling filter (TF) for the treatment of sewage. It is an attached growth system, on the surface of which a mixed population of microorganisms forms a slime layer. Rocks, plastic, metal, and other materials are possible for the fixed media in trickling filters. There is no filtration or straining involved in the Trickling Filter. After basic wastewater treatment, the wastewater is pumped through the filter, where it develops a gelatinous covering of bacteria, protozoa, and other organisms. In a circular tank, the wastewater is sprayed through a layer of coarse stones or compressed plastic.

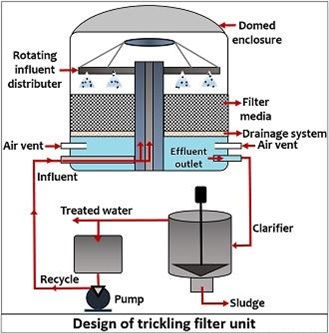

The wastewater from the top of the bed is distributed uniformly by a rotating distributor, which is a spinning pipe with numerous holes across it. A system of under-drain pipes collects the wastewater as it trickles down. The waste water's microorganisms connect to the filter material in the bed, decompose the organic stuff, and remove it from the wastewater.

In this blog, we will discuss in detail about the trickling filter technology for the treatment of sewage and its construction.

What is trickling filter technology in sewage treatment?

The trickling filter (TF) is an aerobic treatment system that removes organic materials from wastewater, by using microorganisms attached to a medium.

Trickling Filter Process

A trickling filter method is a biological system that uses the slime layer to separate, or decompose, the majority of organic and inorganic waste (up to 85%) from primary or raw sludge. A rotating circular distributor, pebble or plastic-filled media, and support structure are all included in the construction of a trickling filter unit.

It operates in an aerobic environment and employs aerobic bacteria to utilise or oxidise the organic material into a simpler form. The filter bed is positioned beneath the media packed with pebbles, which helps separate waste activated sludge from secondary effluent. In order to make the final effluent safe for disposal, disinfectants such as chlorine, ultraviolet light, ozone, and other substances are added, after it is released from the outlet pipe.

Construction of trickling bed filters

1: Filter Media

Useful filter media include:

· packed bed with crushed rock

· small shattered rock

As filter media, crushed rocks are frequently employed. Stones smaller than 75 mm in size do not have enough pore space, and may cause the media to clog. Although, stones larger than 75 mm tend to prevent ponding conditions, they also reduce the amount of surface area per accessible volume, for the slime layer to grow. The stones can only be as large as 150 mm. As a result, the material is graded to a consistent size between 75 and 150 mm. Stone media can be found up to a depth of 1.5 to 2.0 metres.

2: Plastic packaging

The success of the trickling filter can be attributed in great part to the use of thermoformed PVC or synthetic media, such as plastic rings and saddles. This development makes it possible to build modules with greater compressive strength and higher void volumes, which are required for stacking to heights that are not possible with rock filters.

Bio-towers are filters with plastic material that can reach heights of up to 12 m. Higher organic loadings are made possible by increased specific surface area. Due to their higher void volumes, deeper bio-towers can be easily ventilated using blowers.

3: Rotatory Distributor

Due to its dependability and ease of maintenance, the rotary distributor is utilised to spray waste water over the filter media of the Trickling Filters. The rotary distributor is made up of a hollow vertical central column that supports two or more radial pipes or arms, each of which has a number of orifices or nozzles, for directing the waste water onto the filter medium.

These nozzles are all at right angles to the arms and aim in the same general direction. The spray heads revolve above the media due to the force of the water, behaving as sprinklers and dispersing waste water uniformly. A head measuring between 450 and 600 mm provides the rotary reaction.

The rate of revolution will vary depending on the flow rate, but for a two-arm distributor, it should be no more than one revolution every ten minutes.

The Trickling water treatment's bottom is where the liquid in flow is pumped

At the top of the trickling filter are filters for the distribution (rotating arm) heads. The wastewater leaving the arm horizontally creates a jet that powers the distribution head, which is often not motorised. The performance of trickling filters is significantly enhanced and the issues with the older rotary distributors are eliminated, with the use of motor-driven rotary distributor centre mechanisms.

Between the top of the media and the bottom of the distribution arm, there should be a clearance of 150 to 250 mm. As a result, the waste streams from the nozzles will be able to disperse and evenly cover the media. Fixed flat-spray nozzles have been employed in some instances, particularly with Trickling Filters that are square or rectangular.

4: Drainage system

After secondary sedimentation and tertiary treatment using a membrane filter like RO Plants, the wastewater from the trickling filter bed is discharged into the drainage system. A secondary clarifier is a sedimentation device that removes from waste fluid, the smaller colloids, suspended particles, etc. near the bottom.

In addition, as the tertiary treatment removes the pathogenic bacteria, it is also essential for the effluent's safe disposal. A return pump is used to slough down and recycle organic material that has been oxidised, or degraded back into the trickling filter.

System of under drains

Trickling Filters' under-drain mechanism accomplishes tasks like:

· To maintain aerobic conditions,

· To provide for filter ventilation, and

· To collect as well as to transport the wastewater passing through the filter, and the sloughed solids to the Secondary Sedimentation Tank.

Leading providers of Sewage Treatment Plants in India

Various businesses and industries can get in touch with the water treatment specialists, at Netsol Water for a number of cutting-edge sewage treatment methods, including aerobic and anaerobic wastewater treatment. For a range of sectors, we have also produced and designed unique biological wastewater treatment systems, like trickling filters.

We have also been offering municipalities wastewater treatment services for a long time. These services include phosphate removal, odour control, sludge dewatering, chlorination and dechlorination, and water clarification, etc. For further information, contact us by phone at +91 9650608473 or by email at enquiry@netsolwater.com.