If you work in industrial manufacturing or the wastewater treatment industry as a plant manager, process engineer, purchasing, or Environmental Health and Safety (EHS) professional, you may be looking for a solution to remove harmful pollutants and odours from your process exhaust streams, before they are released into the atmosphere and contaminate the outside air.

The industrial wet scrubber is one such technique requiring serious study.

Industrial wet scrubbers are pollution filtration devices that eliminate gas pollutants and odours, from exhaust streams by using solids in "dry scrubbers", or water or other liquids in "wet scrubbers".

What is a Wet Scrubber?

A wet scrubber, also known as a wet scrubber system, is a type of scrubber used to remove dangerous elements from industrial exhaust gases, also known as flue gas before they are released into the environment. It was the first scrubbing system, and it uses a wet solution to eliminate acidic gases that lead to acid rain.

Working of a wet scrubber

Flue gas is channelled through an area and sprayed with a wet substance, while utilizing a wet scrubber. When removing dust and particle matter, water is utilized, but additional chemicals can be used.

These chemicals are chosen to react particularly with specific airborne pollutants, which are typically acidic gases. When the exhaust is vented, considerable volumes of vapour are added, resulting in the discharge of exhaust that appears as white smoke.

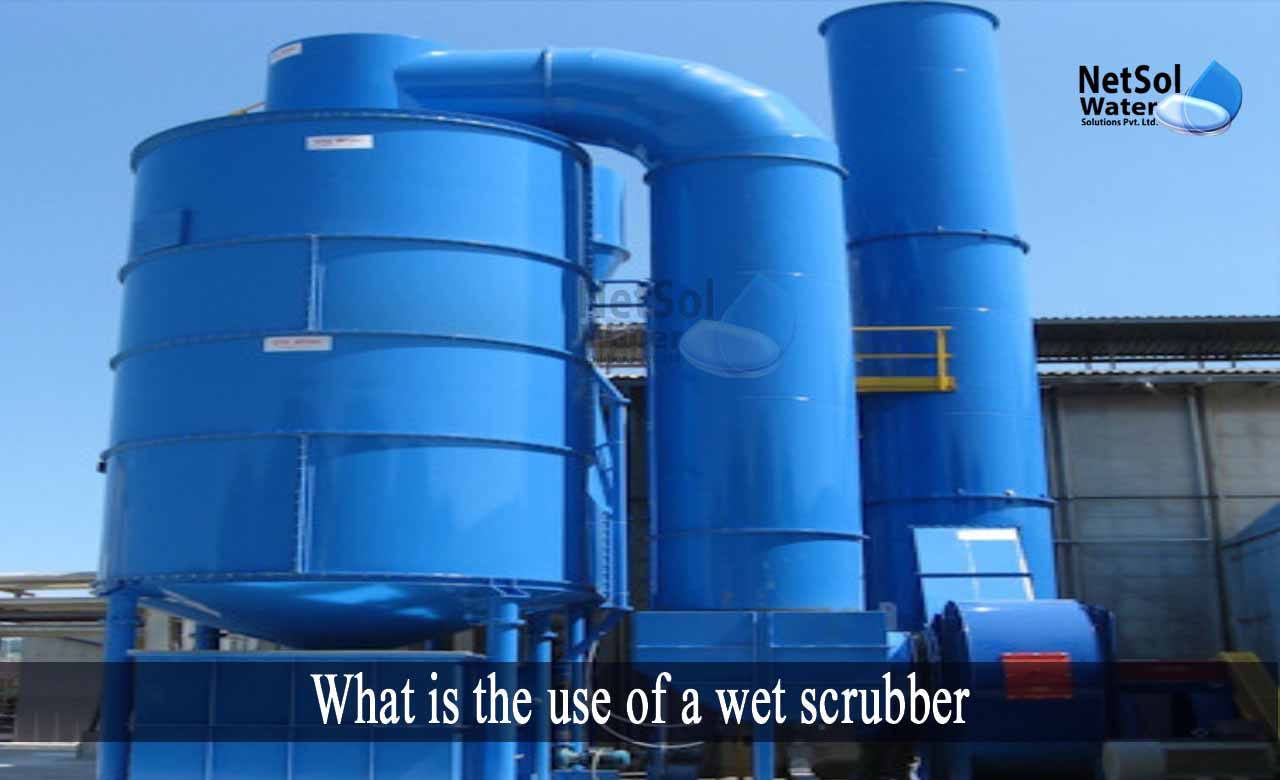

What is the use of a wet scrubber?

Wet scrubbers are specialized devices that remove a wide range of pollutants from the exhaust gas, of furnaces and other devices. To eliminate contaminants, these gadgets employ a cleaning liquid.

Typically, the exhaust gas is misted through the scrubbing liquid as it passes through a chamber. The gas then exits without the impurities and pollutants present. Because, of the chemical nature of the liquid, when the gas is sprayed with it, heavier contaminants are drawn out of the gas and cling to it. The pollutants are attracted to the cleaning mist and left behind, as the gas passes through it.

Misting Method in Wet Scrubber

While, misting is a popular method of cleaning exhaust gas in wet scrubbing, another design encourages the gas to bubble through a pool of scouring fluid. However, the procedure for eliminating the impurities is largely the same, because the contaminants attach to the fluid when the gas is filtered through the pool. This cleans the gas as it exits and leaves the pollutants in the pool.

Design of a Wet Scrubber

Most wet scrubbers are designed in a similar manner, regardless of how the scrubbing fluid is introduced. To drive gas through its chambers, a standard scrubber is made up of ducting and a fan system.

There is also a pump, a collection area for used scrubbing liquid, and some techniques to separate the used fluid from the cleaned gas. The liquid sprayed through the exhaust gathers at the bottom of the chamber, where the spraying takes place. Because, of the potentially hazardous elements present in it, this liquid is channelled away and collected for specialized disposal.

Because, of its chemical composition, this liquid cannot be simply discarded or reused. These scrubbers are commonly employed in manufacturing plants that treat propane and other types of natural gases.

Advantages of Wet Scrubbers

· First and foremost, these scrubbers are advantageous because they prevent a variety of contaminants, from entering the air via exhaust gas.

· Second, these devices are reasonably robust and can withstand a wide variety of temperatures, making them suitable for use in practically any environment.

· Finally, wet scrubbers can be used to remove a variety of pollutants, including sulfur and acidic gases, which contribute to acid rain.

Conclusion

Wet scrubbers are a type of devices that eliminate pollutants from furnace flue gas or other gas streams. The dirty gas stream is brought into contact with the scrubbing liquid in a wet scrubber, by spraying it with the liquid, driving it through a pool of liquid, or by some other contact method to eliminate the pollutants.

How can we assist?

Netsol Water provides expert guidance and technical support for all air, water and wastewater related issues. Our certified specialists have worked on a wide range of wet scrubbers in a variety of sectors.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.