What is an aeration basin?

Aeration is the process of introducing air into wastewater in order to promote aerobic biodegradation of organic compounds. Aeration basins (also known as aeration lagoons) are holding and/or treatment ponds that use artificial aeration to promote the biochemical oxidation of wastewaters.

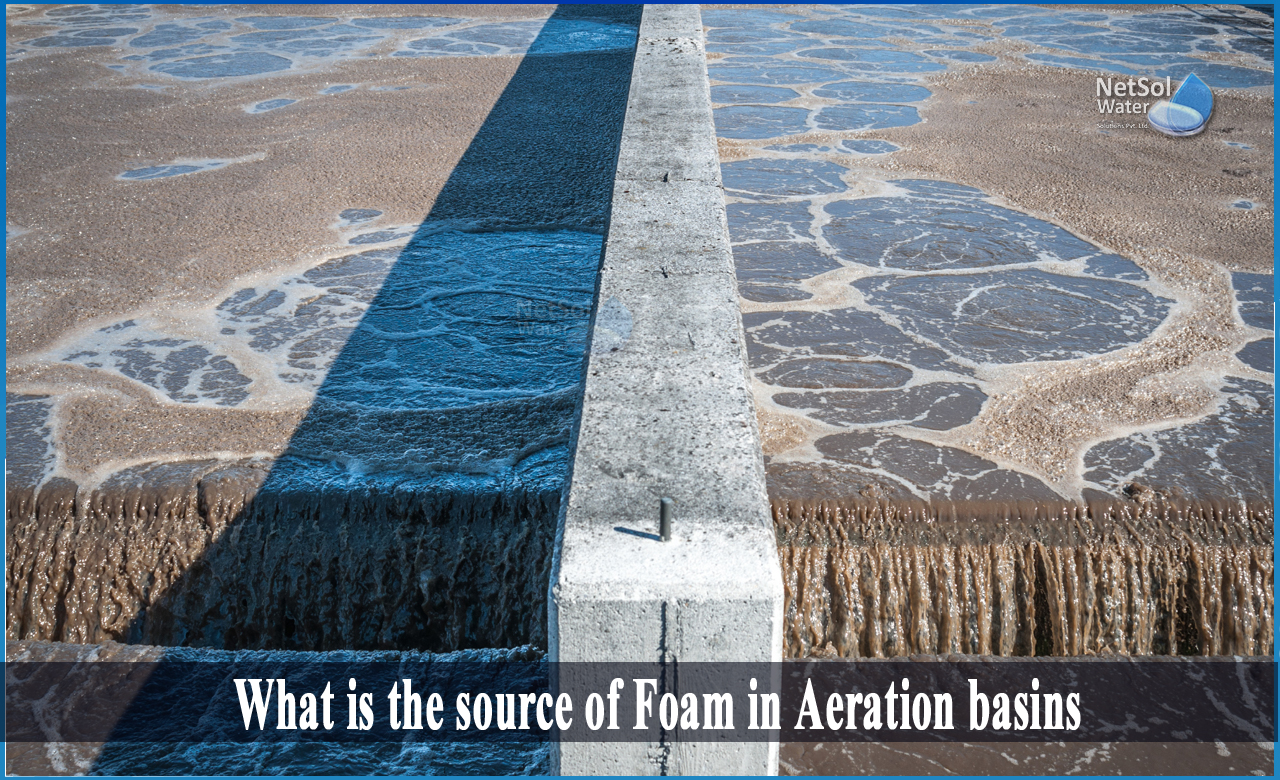

What is the source of Foam in Aeration basins?

This is the common light foam found on basins. The foam is produced by biological by-products such as proteins, polysaccharides, and biosurfactants, which are essential components of microbial activity.This foam is white to light brown in colour and quickly collapses when sprayed with water. It is typical to notice more foam when starting up a fresh aeration tank because quickly dividing bacteria releases more cellular by products than a more stable, decline phase growth system. It is generally beneficial to use an anti-foam solution to reduce foaming during starting or with higher loadings.

Foam of Fat, Oil, and Grease

A FOG test measures the hydrophobic components of systems that receive food processing, dairy, or petrochemical waste.While the chemicals alone generate a more stable foam, bacteria charged with decomposing FOG compounds produce bio-surfactants that solubilize organics for transfer through the cell wall. These systems frequently require anti-foam additives, while updated aeration and mixing settings/equipment can reduce the requirement for chemical addition.

Foam of Surfactants

Following cleaning or firefighting (foam usage) in surfactant manufacture and other industries, we frequently witness a highly solid, white foam on the aeration basin. Surfactant-based foam, unlike biological foams, cannot be decreased by a water spray and must be controlled using anti-foam.

Nocardia & Filamental Foams

Some wastewater organisms have hydrophobic polymers, which produce a "greasy," brown scum/foam that may be a major issue in aeration basins. Control of "nocardia foam," named after one of the most prevalent microbiological types creating the foam, sometimes necessitates many measures. First, because the foam holds the germs, regular waste is ineffective in decreasing the harmful microorganisms. Manual foam skimming, RAS chlorination, and an anti-foam program are frequently necessary. Long-term control may be maintained by limiting the amount of FOG entering the system and the age of the sludge.

Antifoam Replacements

Microbial activity is the direct source of foam. Netsol Water has worked on a number of systems that have a proclivity to foam and a high proportion of influent FOG. While anti-foaming and chlorination (filament-based foams) are fast fixes, long-term management requires having the biomass in a state suitable for the influent. We discovered that introducing bioaugmentation cultures can help mature the biomass and add a large number of organisms capable of degrading target chemicals like surfactants and grease. In situations of Nocardia, bioaugmentation cultures used in conjunction with RAS chlorination can help shift the balance towards beneficial microorganisms. It is always more complicated than just introducing the bioaugmentation cultures. Understanding the reasons and improvements that may be done to assist regulate the foam, as well as introducing bioaugmentation cultures or other chemicals, are important variables.

What do we offer?

If you want to know more about foam in aeration basins, you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial water treatment plants and wastewater treatment plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Call us on +91 9650608473 or contact via email at enquiry@netsolwater.com for more information or product purchase related query.