What is the purpose of using Zero liquid discharge (ZLD) plants?

Freshwater availability is under threat from industrial operations on two fronts in a world, where it is becoming an increasingly important resource unless the water is cleaned.

As we already know that water is needed for many industrial operations, but as a result of industrialization, less water is available for the environment or other processes, and alternatively, contaminated water is released into the environment, causing harm.

Therefore, we have to use technologies that may save our water resources, as well convert our fresh water into a useful resource. One such technology is ZERO LIQUID DISCHARGE. So, let’s understand the purpose of using ZLD Plants.

Zero Liquid discharge

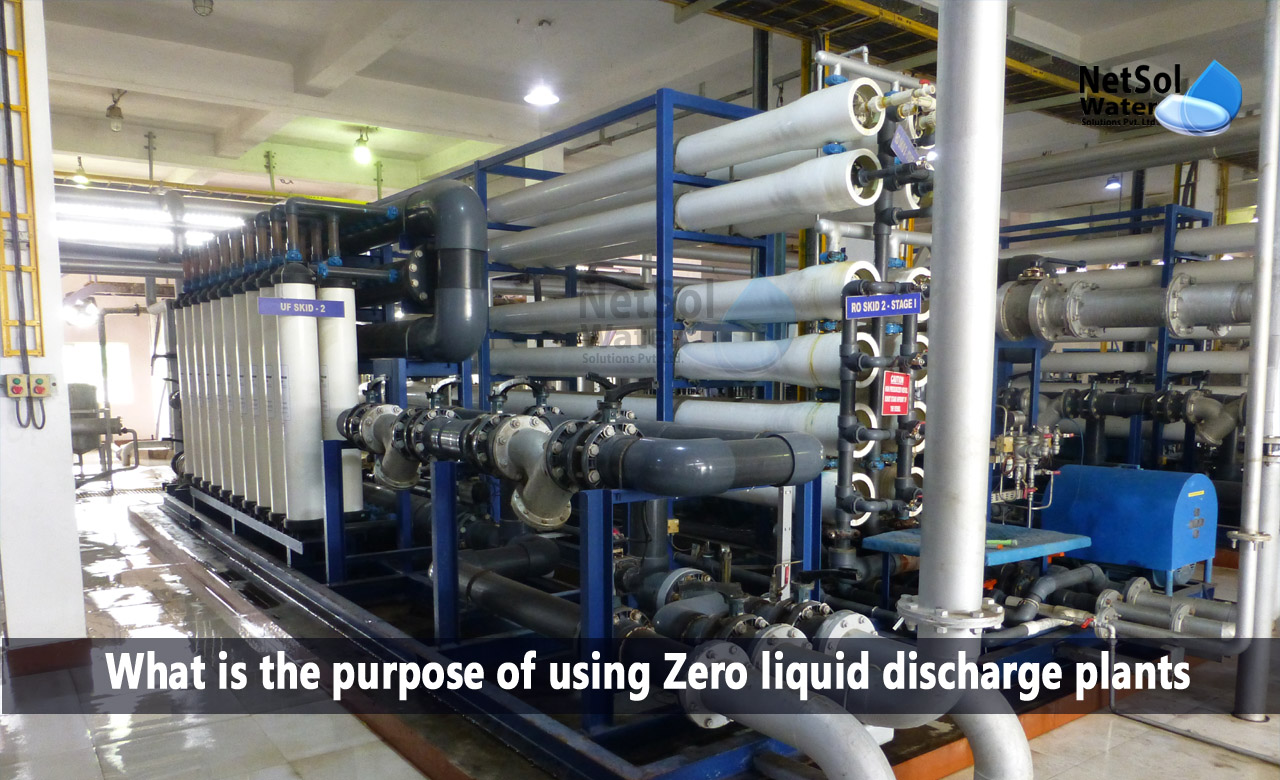

A ZLD treatment system, as the name suggests, uses cutting-edge modern water treatment procedures to reduce liquid waste, at the conclusion of your industrial process to zero.

A ZLD treatment system that is effective and properly thought out, should be able to:

1. Adapt to fluctuations in the flow and contamination of waste.

2. Allow for necessary changes to chemical amounts.

3. 95% or more of your liquid waste can be recovered for reuse.

4. Treat your waste to recover useful by-products (i.e. salts and brines).

5. Create a solid, dry cake for disposal.

The term "zero liquid discharge" (ZLD) thus refers to a technical method of treating water, in which all water is recovered, and contaminants are turned into solid waste.

Purpose of Using Zero Liquid Discharge Plants

While, many wastewater treatment technologies aim to enhance freshwater recovery and minimize waste, ZLD is the most difficult goal to achieve because recovery costs and difficulties rise as wastewater concentrations rise.

Concentrations of salinity, scaling compounds, and organics all rise, adding to the costs of regulating these increases. Thus, ZLD is made possible by combining wastewater treatment technologies that can handle wastewater when the toxins are concentrated.

Why is Zero Liquid Discharge important?

India has been at the forefront of the movement for zero liquid discharge restrictions for the past ten years, even though tougher regulations on wastewater discharge have a long history. Nations have established policies that demand zero liquid discharge due to industrial wastewater's substantial pollution, of multiple significant rivers.

They concluded that keeping rivers and lakes clean is the best way, to guarantee a secure water supply in the future. In India, the significant expenses of wastewater disposal at inland facilities, have pushed the country's efforts towards zero liquid discharge. Regulations that restrict disposal alternatives and variables affecting disposal technology costs, are both responsible for these expenditures.

The possibility of recovering resources from wastewater is a crucial justification, for zero liquid discharge. Because, ZLD can sell the solids created or reuse them as part of their industrial process, some organizations target ZLD for their waste.

Conclusion

Stricter environmental rules on wastewater discharge are anticipated, as the serious effects of water pollution are recognized, and garner more public attention, which will drive more high-polluting businesses toward ZLD.

What do we offer?

Whatever the organization's reasons for aiming for zero liquid discharge, doing so indicates sound business practices, corporate accountability, and environmental stewardship.

Operating an internal ZLD plant can save disposal costs, increase water reuse, and reduce greenhouse gas emissions from off-site trucks, reducing the impact on regional ecosystems and the climate.

Netsol Water is one of the top water and wastewater treatment companies in India, manufacturing and supplying equipment for water and wastewater treatment plants, which not only convert your wastewater into usable water but also protect Mother Earth and her priceless resources.

For further information or to make a product purchase, contact us at +91-9650608473 or enquiry@netsolwater.com