To find the best chemical treatment and associated chemical dosages for a particular water or wastewater stream, jar testing is an excellent technique for mechanically and physically testing chemical treatments, on samples of water and wastewater.

Jar testing is essentially a diluted form of a water purification system. It is excellent for gaining a "snapshot" of what will be required, to treat the water more extensively. It is crucial to remember that even if a treatment is effective in jar testing, actual on-site trials and scaling up are still necessary, to confirm the suggested programme and identify any necessary improvements. In this article, we will understand the importance and the procedure of Jar test.

Why should you conduct jar tests?

1: By carrying out jar tests, you can compare the outcomes of several different chemical treatments for time of formation, floc size, settleability, and possibly filtration characteristics, without affecting the operation of the full-scale water/wastewater treatment plant.

2: You can also try out different treatment doses and strategies, without affecting the performance of the treatment plant. Such comparisons with the treatment of the entire plant are invalid.

3: Saving money is a key factor in the decision to undertake jar testing. Overfeeding or overdose, particularly with coagulants, is one of the main issues in the treatment of water. Although, it might not lower the quality of the water, but, this can be very expensive.

4: Jar testing is one of the simplest things a plant operator can do to optimise the plant, and it is essential when looking at best practises.

5: Jar testing is helpful because it can reveal the composition of a particular waste stream, and reveal whether a pH correction, filtration, or a different chemical load than anticipated, would be needed for the wastewater sample. Each sample of wastewater has a different composition, necessitating a different course of action. The best and most effective method for choosing the finest treatment system is to conduct jar tests.

Which equipment’s are used in a jar test?

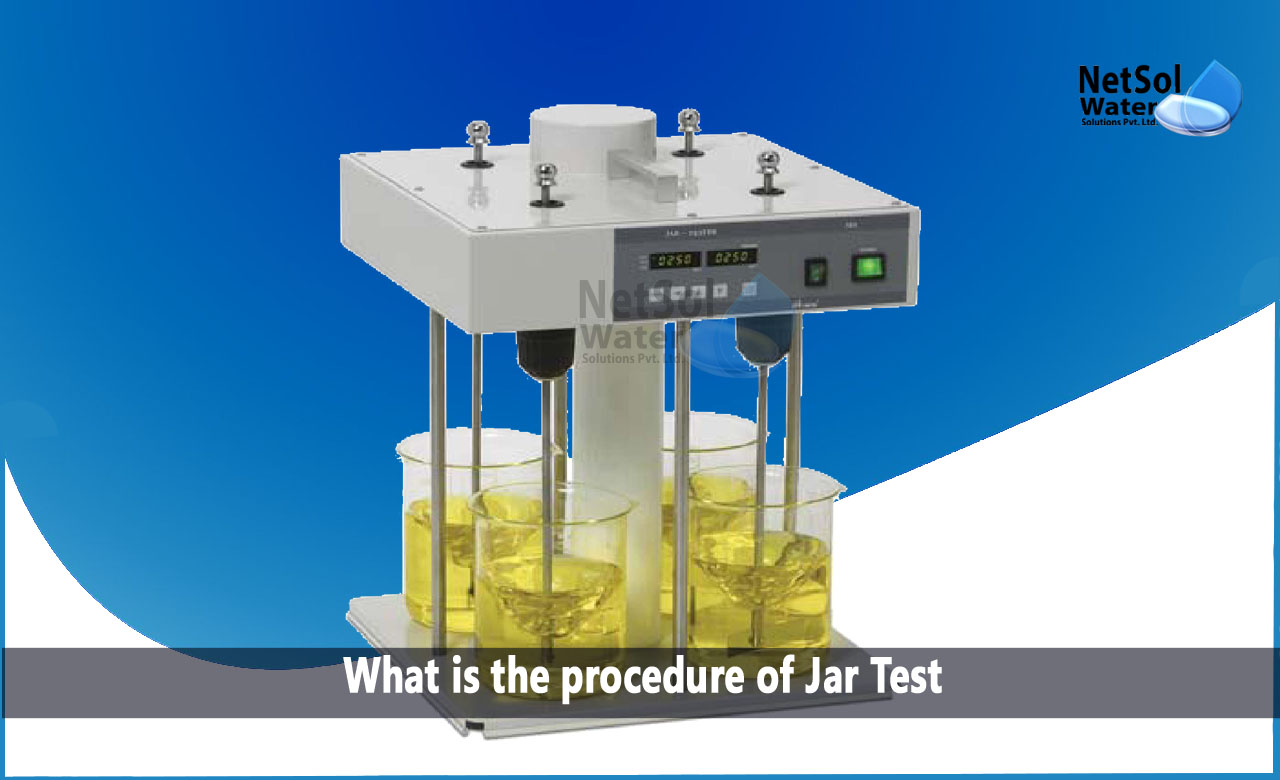

1: Gang-stirrer: The ideal method for conducting extensive jar testing is to employ a device known as a gang stirrer. A gang stirrer is a device that can stir several water beakers at once, allowing several different compounds or dosages, to be evaluated on a sample simultaneously. The device also makes sure that the mixing is consistent throughout all of the samples. Even without a gang stirrer, you can still finish a jar test. Choose something that can be used to completely mix the water, and get a beaker or another container to hold the liquid.

2: Chemicals: The chemicals you intend to test on the water must be purchased once your stirring system is set up. There should be a coagulant, flocculant, or both in the chemical mixture. Because, some waste streams need to have their pH adjusted in order to be treated, an acid or base is occasionally also required.

3: Additional equipment’s: Syringes, pH metres, magnets, a notebook, and a pen are additional tools needed for efficient jar testing.

Complete list of the tools needed for jar testing

· Mixing apparatus, which may include a gang stirrer or magnetic mixing plates

· Glass bottles

· Beakers

· Syringes

· Chemicals

· pH paper or metre

· Graduated Timer

· Cylinder

· Magnets

· Notebook

Selection of chemicals for Jar Testing

Usually, two separate chemicals are employed to conduct a jar test. It can also be necessary to modify the pH of the wastewater being used in the test. It's crucial to consider the order of chemical additions.

1: pH Adjustment

Coagulants and flocculants may occasionally not function at a specific pH. Sometimes what we refer to as "Acid crack" is necessary for an oily waste stream. These oils are removed from the water when the pH of the oily water is adjusted with an acid. Treatment is greatly simplified by this. After acid cracking, you can use a base or caustic soda to raise the pH back to the desired level.

2: Coagulant addition

When coagulants are added to the wastewater, their positively charged molecules destabilise the water's negatively charged particles. "Pin flocs" are produced during the coagulation process. These are the small and neutrally charged molecules. Pin flocs will eventually settle, but because they are lighter than bigger floc particles, they may remain suspended for a longer period of time.

3: Flocculant addition

Compared to coagulants, flocculants connect more particles to a polymer chain because they have longer polymer chains. The term "macrofloc" refers to solid clumps that are larger than pin flocs, and are produced by flocculants. Because they are heavier than pin flocs, macroflocs will settle more quickly.

What is the procedure of Jar Test?

The following jar test process makes use of an ordinary six-gang jar tester, and a substance used in water treatment for coagulation and flocculation. The outcomes of this technique can aid in improving the wastewater treatment plant's efficiency.

1: Fill each of the jar test beakers with 1,000 mL of raw water using a 1,000 mL graduated cylinder.

2: Before starting, note the raw water's temperature, pH, turbidity, and alkalinity.

3: After that, make a stock solution by combining 10.0 grammes of coagulants such as alum, with 1,000 mL of distilled water. When added to 1,000 mL of test water, this stock solution will make each 1.0 mL equal 10 mg/L (ppm).

4: Dose each beaker with increasing amounts of the prepared stock solution of alum.

5: Switch on the stirrers after dosing each beaker. This step of the procedure should correspond to the plant's actual conditions as much as possible. In other words, if the plant follows chemical addition with a static mixer, then 30 minutes in a flocculator, followed by 1.5 hours of settling time before the filters, then the test should follow suit.

6: To mimic a static mixer, run the stirrers at a high RPM for one minute.

|

Jar No.

|

mL of alum stock added

|

mg\L of alum dose

|

|

1 2 3 4 5 6

|

1 1.5 2 2.5 3 3.5

|

10 15 20 25 30 35

|

7: After that, adjust the stirrers' speed to the flocculator's parameters and let them run for 30 minutes.

8: Over the course of the 30 minutes, keep an eye on the floc creation. Turn off the stirrers and let the mixture settle once the 30 minutes have passed. Within an hour, the majority of the settling will be finished.

9: Now examine the beakers to see which jar produced the greatest results. If there were no obvious results, then for the following six jars, raise the dosage using the table above. A low feeding will result in a cloudy-looking sample in the beaker.

Factors to consider while conducting jar test

1: The coagulant ingredient is introduced to the water sample beakers using a flocculator. The contaminants are trapped as the chemical coagulant begins to precipitate, generating flocs that will settle to the bottom of the beaker.

2: The sample is continuously churned so that it is possible to see how floc forms, develops, and settles just as it would in a real water treatment facility.

3: The operator then conducts a series of experiments, to examine the results of various dosages of flocculation agents at various pH levels, in order to identify the proper floc size.

The following analytic scenarios frequently involve the use of a flocculator:

· 1000 ml tall, 105 mm glass beakers (jars).

· Coagulant and 600 cc of wastewater samples

· Paddle height: centred above the sample

· Stirring at 120 rpm for 120 seconds

· Moderate speed flocculation: 30 rpm, 25 minutes

Evaluation of the results for optimal performance and large-scale implementation

Several standards can be used to evaluate the Jar Test's outcomes, including:

· Evaluation of the Floc dimension to a numerical degree

· The amount of time between adding chemicals and when flocs first appeared

· Turbidimeter evaluation of the supernatant's remaining turbidity, following a specified sedimentation period

· Analysing the electro-kinetic potential of suspended particles on a sample collected, right after chemicals have been added and mixed

· By using standardised membrane filters under pressure, clarified water's filterability is assessed

· The filter clogging that is brought on by lingering, and the unsettled suspended debris, is correlated with the reduction in the water flow.

There are a few further measures you might take to determine whether the water fulfils your treatment objectives.

The water can be filtered and its turbidity measured using a turbidity reader, examined for clarity and appearance, or passed through various micron-level filters. If the clarity and floc formation fall short of your treatment objectives, different coagulants or flocculants should normally be investigated. Choose more products, and then repeat the steps to continue the treatment as desired.

Conclusion

The Jar Test aids lab operators in water treatment plants in avoiding overfeeding or overdose, particularly when using coagulants to conserve resources and improve workflow. Results must be interpreted in light of the particular waste stream and treatment objectives. There are occasions when crystal-clear water is required and times when semi-clear water is required.

It is crucial that observations of jar testing take into account how the actual treatment system is constructed, and that every attempt is made to accurately represent actual treatment settings. When doing jar testing, it's important to take a number of variables into account, including the chemical contact duration, mixing energy, settling time, volume of solids, solid de-waterability, and shearing potential.

Specialised wastewater treatment solutions from leading manufacturer and supplier of wastewater treatment plants in India

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment plants and wastewater treatment plants in India.

We also manufacture and supply reverse osmosis plants/RO Plants, effluent treatment plants or ETPs, DM plants, water softeners, Ultra filtration plants or UF Plants, UV water systems, sewage treatment plants or STPs, Zero liquid discharge or ZLD plants, and other goods and services. We provide Jar testing services and wastewater treatment solutions to businesses, including automotive, beverages, pulp & paper, refineries, pharmaceutical, textile, hotels, schools, hospitals, office buildings, etc.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.