The treatment of sewage and wastewater is a multi-stage process designed to remove contaminants before the treated effluent can be safely discharged into receiving waters or even reused for certain non-potable purposes. One of the critical final steps is disinfection to inactivate any remaining pathogenic microorganisms that made it through the solids removal and biological treatment stages.

Among the various disinfection methods available, chlorine treatment remains the most widely used for sewage effluent due to its proven effectiveness, relatively low cost, and widespread availability. Chlorination provides a barrier against viruses, bacteria, and protozoa that could otherwise spread waterborne illnesses if released untreated.

We will explore how chlorine disinfection works, its advantages and limitations, and best practices for sewage treatment plant implementation.

What is the Mechanism of Chlorine Disinfection?

Chlorine is introduced to effluent streams as elemental chlorine gas (Cl2), sodium hypochlorite solution (NaOCl), or other chlorine compounds. Once dissolved, the chlorine species present hydrolyse into hypochlorous acid (HOCl), which is the primary disinfecting agent.

HOCl is a powerful oxidiser that can inactivate microbes through several mechanisms. It diffuses through cell walls/membranes and chemically disrupts enzymes, proteins, RNA/DNA, and other cellular components essential for survival and reproduction. Chlorine's mode of action works against diverse pathogenic targets, including:

• Bacteria - Salmonella, Shigella, E. coli, Vibrio cholera

• Viruses - Noroviruses, Hepatitis A, Enteroviruses

• Protozoa - Giardia, Cryptosporidium

Even highly chlorine-resistant protozoan cysts like Cryptosporidium oocysts can ultimately be rendered nonviable with sufficient chlorine residual concentrations and contact times.

Disinfection Efficacy Factors

The overall efficacy of chlorine disinfection depends on the chlorine dose, residual concentration after the specified contact period, and numerous water quality parameters like:

• Organic matter/ammonia content depleting chlorine

• pH impacting chlorine speciation to less effective hypochlorite

• Temperature affecting reaction kinetics

• Short-circuiting in chlorine contact tanks

• Particulates shielding microbes from chlorine exposure

Biological treatment processes reduce organic loads before disinfection allows chlorine doses to go further before being consumed. Engineered chlorine contact tanks/basins provide turbulent mixing and sufficient hydraulic residence times for adequate microbial inactivation.

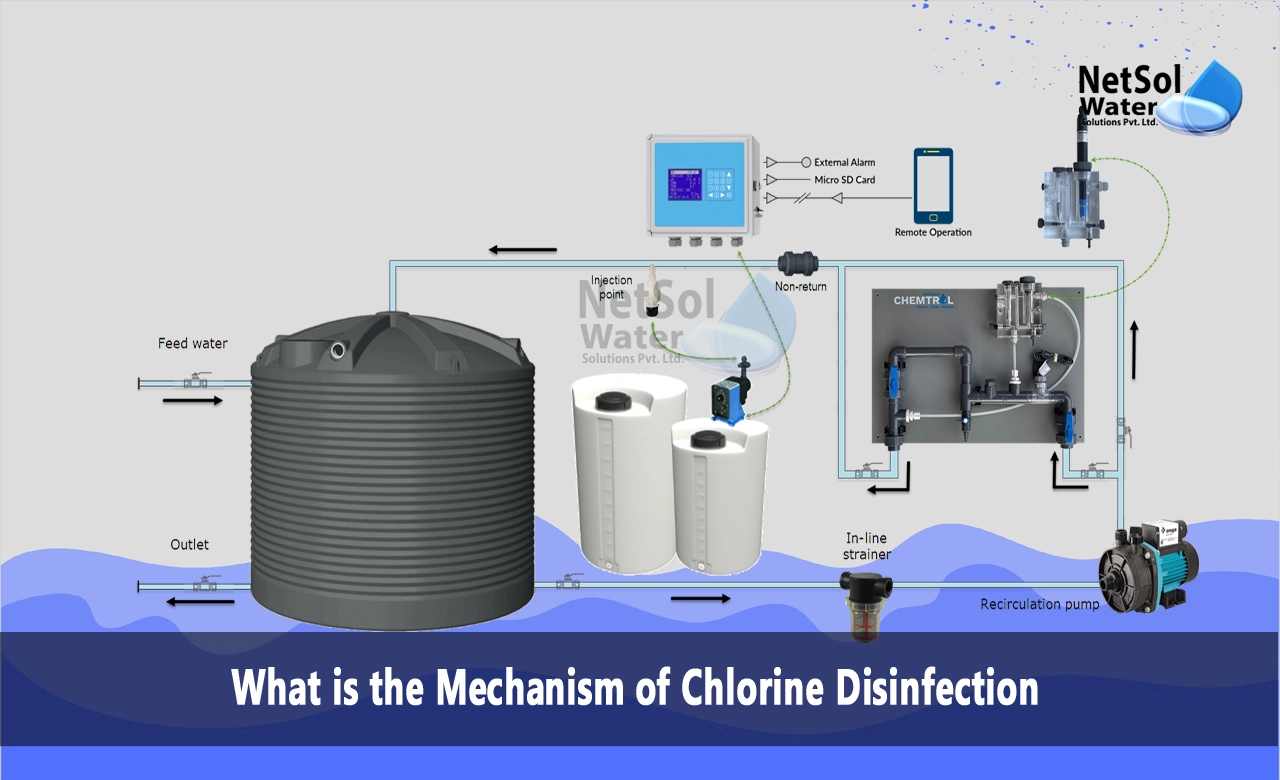

Chlorine Dosing Systems

Most sewage treatment plants utilise on-site hypochlorite generation systems, avoiding hazards of transporting/storing concentrated chlorine gas. Saltwater is electrolysed to generate a sodium hypochlorite disinfectant solution, which is dosed into the effluent stream.

Alternatively, calcium or sodium hypochlorite solids can be mixed into disinfection solution tanks and metered into effluent flows. Gaseous chlorine systems are becoming less common but are still used at select large facilities. All systems require leak detectors, scrubbers and other safety provisions.

Online analysers like sensors continuously monitor residual chlorine concentrations to automate dosing and optimise dosages. Many plants supplement with UV irradiation or alternative disinfectants as added microbial barriers.

Environmental Tradeoffs

While highly effective at disinfection, chlorine treatment creates its own environmental issue - residual chlorine and combined chlorine disinfection byproducts are toxic to aquatic life in receiving waters. Plants must dechlorinate toxic chlorine species before final discharge using reducing agents like sodium bisulfite, though this adds to operational costs.

The presence of ammonia in sewage effluents also drives the formation of mutagenic chloramines that facilities must remove. Some jurisdictions are restricting chlorine disinfection in favour of UV irradiation, which avoids toxic residuals but at higher capital/operating costs for large-scale wastewater treatment plants.Overall, sewage treatment plants carefully balance disinfection efficacy against chlorine dose rates,minimising environmental impact on receiving waters. Optimising biological treatment to reduce chlorine demands helps strike that balance.

Conclusion

Fast, affordable and extremely effective, chlorine disinfection enables sewage treatment plants to produce a high-quality effluent virtually free of pathogens capable of causing waterborne disease. However, the process requires careful dosing, monitoring and dechlorination strategies to avoid its own set of environmental impacts with chlorine residuals harming aquatic life.

Sound chlorine contacting equipment and hypochlorite generation systems are critical for maximising disinfection while minimising waste. As tighter environmental regulations emerge, chlorine treatment is likely to cede ground to alternative disinfectants like ozone and UV irradiation. But for now, the combination of efficacy and cost-effectiveness keeps chlorine disinfection widely utilised throughout the wastewater treatment industry.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.