What exactly is "sludge process intensification"?

Intensification appears to be interpreted in a variety of ways. In terms of sludge treatment processes, the most obvious is increasing solids concentration through consolidation. Depending on the technology, there are a variety of methods for accomplishing this. If it's a centrifuge, increased consolidation is achieved by using faster rotation speeds. It's done by increasing the pressure on a filter, belt filter, or screw press, and electrokinetic can be used for simple gravity drainage.

In fact, it is almost always possible to extract a little more water from the sludge, but there are diminishing returns: beyond a certain point, the additional energy required exceeds the potential value derived from a more consolidated product which begs the question:

Where is the final line drawn? What determines the maximum amount of additional energy that can be usefully applied to reducing sludge water content?

Almost always, the answer to this type of question is the same and the answer is, well, it depends!

The most important factor in this case is the intended goal, which is typically one or more of the following:

· Reduce its volume to reduce the cost of transportation/conveyancing

· Render it reusable for land application, which generally means reducing its pathogen content and putrescence, and/or

· Make it more easily treatable by anaerobic digestion, in which the organic carbon is converted to methane by methanogenesis and the sludge is both reduced in volume and rendered innocuous.

What is process intensification?

Process intensification is defined as achieving a significant increase in efficiency by using far less to produce far more. Process intensification aims to reduce capital and operating costs, land requirements, time, input materials, energy requirements, waste generation, nuisances, and risk and hazards. These findings are consistent with the underlying concepts of sustainable sanitation, most appropriate technology, and long-term sanitation.

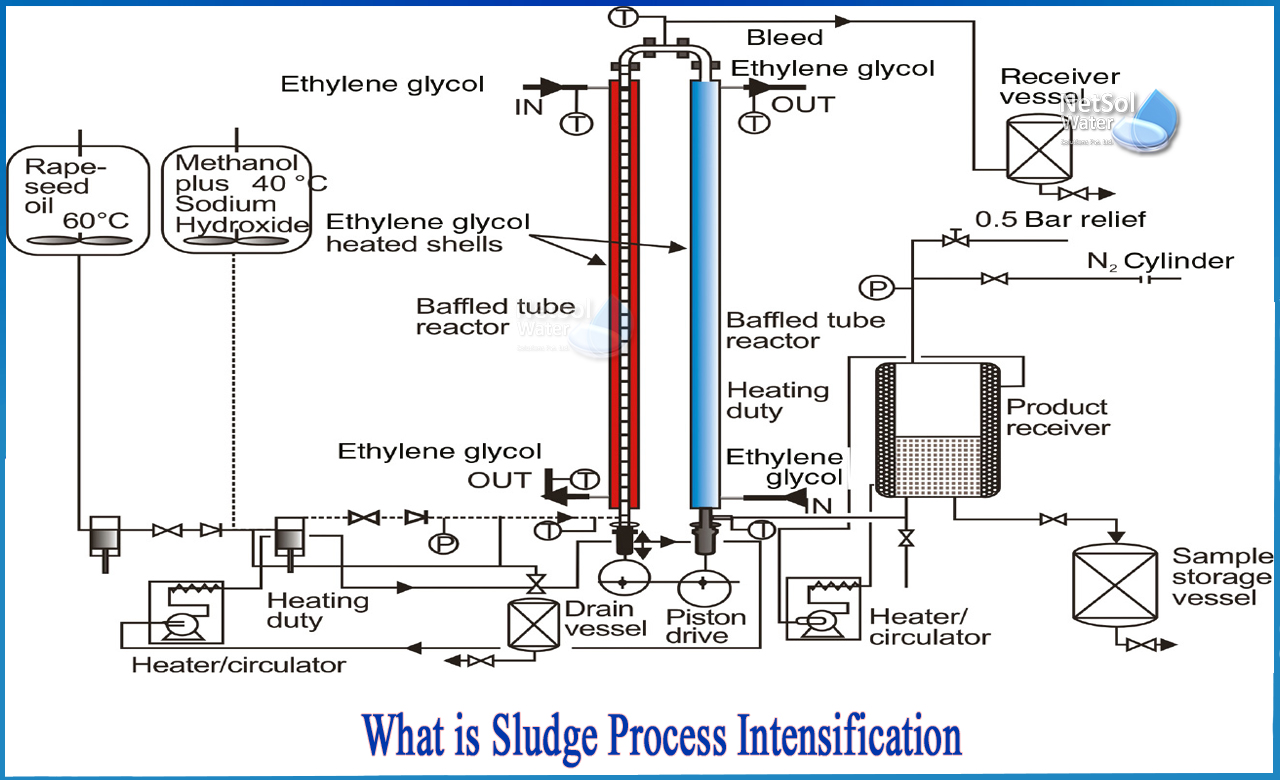

Process intensification can be achieved by "integrating unit operations, functions, phenomena, and targeted enhancements of phenomena in a given operation." In biodiesel production, process intensification has been used to reduce long residence times, high operating costs and energy consumption, and low production efficiency. Through process intensification, it has been demonstrated that the volume of rotating drying beds can be reduced.

There are already a number of sludge processing intensification methods in place for improving solids consolidation or biogas generation. The benefit gained is most often quantified as energy savings, which must be balanced against any additional energy input and/or capital investment required (or embedded carbon, if based on life cycle analysis).

Intensification has an impact on other increasingly important aspects of sludge processing. The fate of macronutrients (nitrate and phosphate) and problematic/harmful bio refractory micropollutants, such as certain pharmaceutical and per fluorinated chemicals, is foremost among these (such as PFAS). If intensification can improve the recovery, retention, or elimination of some or all of these materials, the subsequent additional benefit may eventually outweigh that provided by the more traditional energy-based measure.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.