What is screening process in waste water treatment?

Water screening is a critical feature of all municipal and industrial wastewater treatment plants because it retains particles contained in the wastewater. These solids must be removed at the start of the water treatment process because they can make the entire system less efficient, damage expensive and necessary water treatment equipment, or taint water, creating minor to big scale natural disturbances for a region's entire ecosystem.

Screening degree in wastewater treatment

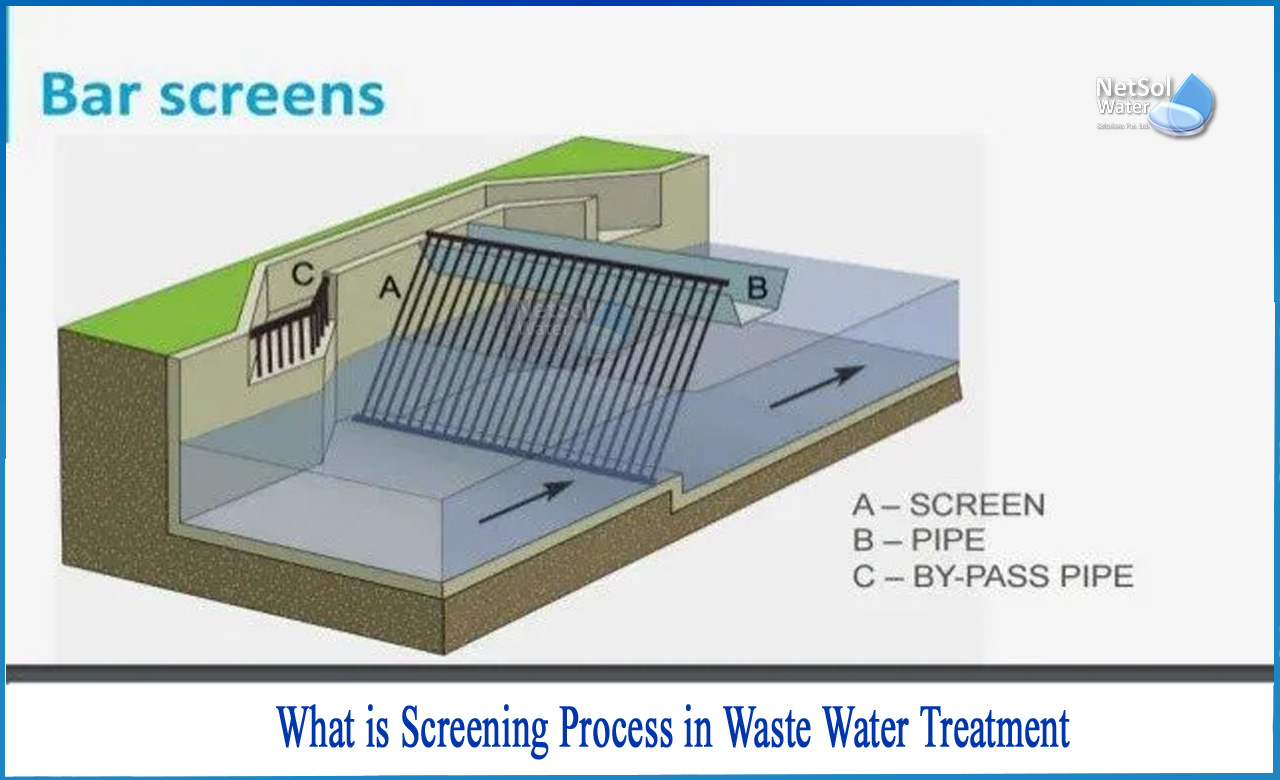

Clear holes on coarse screens range from 6 to 150 mm (0.25 t0 6 in). Coarse screens are made out of parallel bars, rods, or wires, wire mesh, or perforated plates having circular or rectangular apertures. It is also known as a "bar rack" and is used to remove coarse materials like rags and big particles that might clog or damage other appurtenances. Coarse screens are categorized into two sorts based on the wastewater screening process used to clean them:

1: Hand-washed coarse screens

Manually cleaned coarse screens are hand raked and used in the screening process in wastewater treatment at small plants. They are appropriate for use as a backup during heavy flow periods or while more current mechanical screening techniques are being repaired or maintained.

2: Mechanically cleaned screens

Mechanically cleaned coarse screens improve efficiency and decrease issues in the wastewater treatment process.

Mechanically cleaned screens are split into four major categories:

-Chain Driven Screens: These front and back chain driven screens may rake from either upstream or downstream directions. The stream is cleaned automatically by a chain, which improves the overall performance of the wastewater treatment solution.

-Catenary Screens: These front return, front cleaned chain driven screens employ amazing, yet simple, internal mechanics to avoid further jams in the presence of large or heavy items.

-Reciprocating Rakes: Also known as a climber screen, these wastewater treatment screening solutions employ a single rake rather than multiples, making them less efficient when faced with huge loads during the water treatment screening process.

-Belt screen that runs continuously: This form of screening contains several rakes and is continuous and self-cleaning, whether encountering fine or coarse solid loads. It is ultra-high tech, functional, and efficient.

Screens of high quality: Fine screens

Fine screens utilize wire cloth, wedgewire components, or perforated plates to remove particles, whereas coarse screens use bars or rods. Fine screens are used to eliminate particles that may create process equipment maintenance concerns and/or operational problems with the treatment process. Fine screens can be employed in place of primary clarification in smaller treatment facilities.

Fine screen openings are generally between 0.06 and 0.25 inches. Because of the narrower apertures, the fine screens can remove 20 to 35 percent of the suspended solids and BOD. Static wedgewire, rotary drum, or step fine screens may be employed depending on your individual scenario. Static wedgewire screens are commonly seen in industrial wastewater treatment plants and small municipal plants.

Drum screens, as opposed to static wedgewire screens, can accommodate a higher flow rate in a smaller area. Rotary drum screens can be fed either internally or externally. Internally fed drum screens can handle larger flow rates than externally supplied drum screens.

Step screens (sometimes known as stair screens) are a relatively modern technology. Using fixed and moveable plates, debris is hoisted up the screen. This screen's self-cleaning function is provided by the movement of the plate. Another advantage of the step screen is its capacity to produce a filter mat as trapped materials accumulate. This filter mat will improve the screen's solids removal rate.

Screening is critical in the treatment of municipal or industrial wastewater

Screening properly protects wastewater treatment equipment and enhances operation. When choosing a new screen, keep in mind the particle sizes that must be removed.It should also be mentioned that modern screens that combine coarse and fine screening into a single piece of equipment have been created, which may be a superior choice for your screening application.

The three most prevalent forms of fine screening in wastewater treatment are as follows:

- Screens for Drums (rotating cylinders in the flow channel)

- Screens for each step (fixed and movable plates across the width of the channel)

- Static Wedge Wire Screens (used by large treatment plants with ample floor space)

Netsol Water manufactures and installs STP’s, ETP’s and other waste water and water treatment products across India.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.