What is Nitrification and De nitrification?

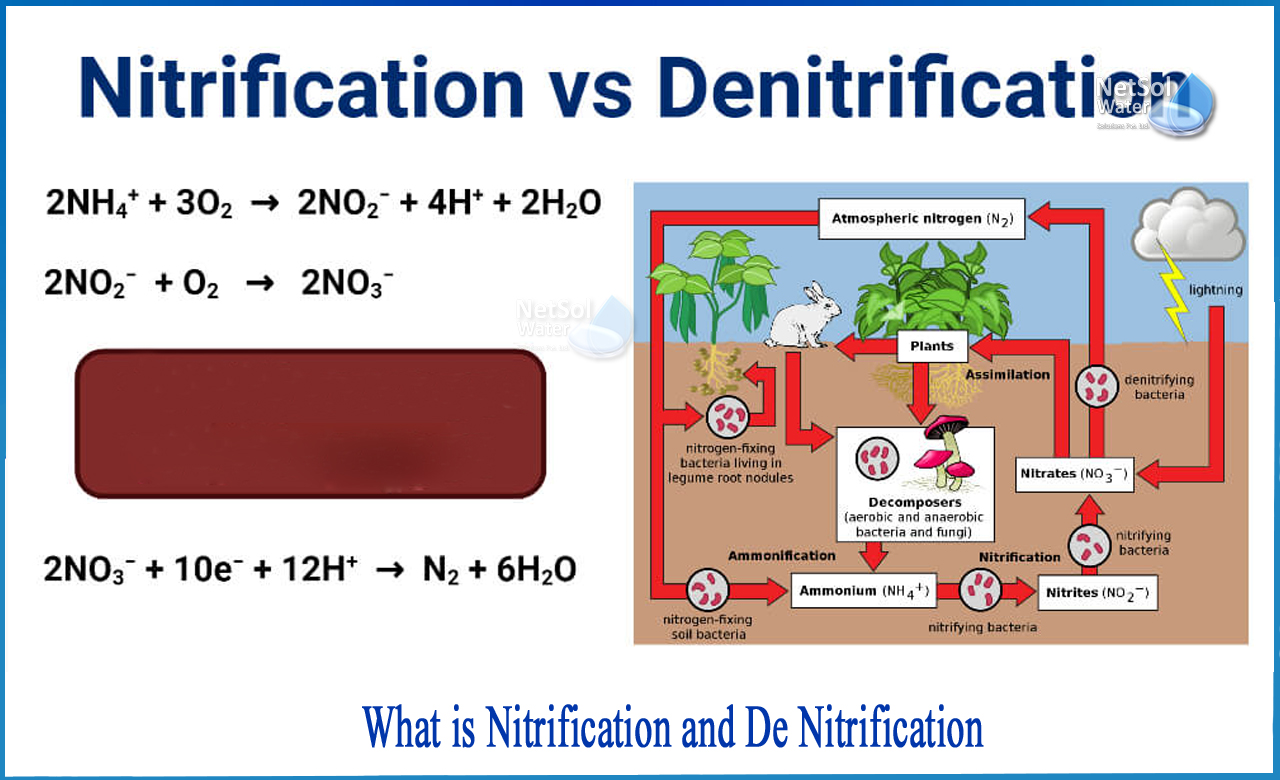

The biological nitrification and denitrification processes remove nitrogen in two steps.

Ammonia is transformed aerobically to nitrate (NO3) in the first phase (nitrification). Under anoxic conditions, nitrates are transformed to N2O or nitrogen gas (N2) in the second phase (denitrification).

The unit processes of nitrification and denitrification can be split into two categories:

(1) The attached-growth systems, and

(2) The systems with stalled growth or Suspended Growth Systems

Attached growth systems vs. Suspended growth systems

The attached-growth processes have a higher nitrification rate than the suspended-growth processes. The effluent from attached-growth operations often contains more suspended particles than that from suspended-growth methods.

The activated sludge and biofilm systems can be further split into systems that use various combinations of combined oxidation–nitrification processes as well as distinct stages of nitrification or denitrification. The attached-growth method normally necessitates more trained operators and more frequent maintenance than the activated-sludge technique.

What is Nitrification?

The biological process of nitrification is the conversion of ammonia to nitrite and ultimately to nitrate. At modest organic loadings and in the presence of adequate environmental conditions, nitrification can be achieved in any aerobic-biological process. In both fixed film and suspended growth systems, nitrifying bacteria grow more slowly than heterotrophic bacteria, which make up the majority of the biomass.

The key condition for nitrification to occur is that the process is so well-controlled that the net rate of biomass build-up, and hence the net rate of biomass withdrawal from the system, is smaller than the nitrifying bacteria's growth rate.

The following are the processes currently employed in the treatment of wastewater for nitrification:

1: Trickling filters: Temperature, dissolved oxygen, pH, presence of inhibitors, filter depth and media type, loading rate, and wastewater BOD all influence the level of nitrification in trickling filters. The growth of a high-nitrifying population is enabled by low-rate trickling filters.

2: Rotating biological contractor: RBC biofilm is formed by microorganisms adhering to the disc surface and forming a 1-4 mm thick biofilm that removes BOD. Only until the BOD has been lowered to around 14 mg/L, does nitrification begin and the rate of nitrification increases with rotation speed.

3: Two-stage activated sludge systems with separate carbonaceous oxidation and nitrification systems: The nitrification process necessitates the use of slow-growing nitrifying bacteria, as well as sludge that has been aged for a long time and a high concentration of dissolved oxygen. These are vulnerable to a wide range of chemicals, even at concentrations that are too low to harm the heterotrophic bacteria.

What is Denitrification?

The biological process of denitrification is the conversion of nitrate to nitrogen and other gaseous end products. The following are the requirements for the denitrification process:

a) Nitrogen in the form of nitrates;

b) A source of organic carbon, and

c) An anaerobic setting.

The following are the biological denitrification processes currently in use:

1: Continuous flow stirred reactor (CFSR): Denitrification processes could be run at close to maximal unit removal rates while still achieving adequate nitrogen conversion (less than 2 mg NO3-N/L in the denitrified effluent). The amount of time cells stay in the reactor is determined by the amount of organic carbon required and the effectiveness with which nitrate is removed.

2: Activated sludge systems: Multiple anoxic zones with a step feed process had recently been modelled and appeared to be the most cost-effective denitrification option since it uses the carbon present in the feed as the carbon source for step feed denitrification.

3: Fluidized bed biofilm reactor: It is discovered that using tiny, fluidized medium in a fluidized bed biofilm reactor (FBBR) allows the FBBR to retain high biomass concentrations while operating at much shorter hydraulic retention durations. It is also claimed that 99 percent of influent nitrates could be eliminated at an empty bed with hydraulic retention durations as short as 6 minutes when volatile solid concentrations are between 30,000 and 40,000 mg/L (when pilot-scale denitrification is used).

What can we offer?

If you want to know more about nitrification and denitrificationin wastewater treatment, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Call us on +91 9650608473