What is membrane and types of membranes are there?

Membranes are becoming more and more common for the enhanced treatment of water, wastewater and desalination, as well as for the creation of potable drinking water from sources of ground, surface, and ocean. Over the past 20 years, these methods have been among the most popular for the treatment of water.

Let us discuss in detail about the membranes and the types of membranes.

What is a membrane?

Membranes are barriers that allow water to pass through while preventing undesirable substances. They are employed in water treatment and wastewater treatment. Similar to how the cell walls in human bodies filter out salts, toxins, viruses, and other particles, these membranes do the same for water.

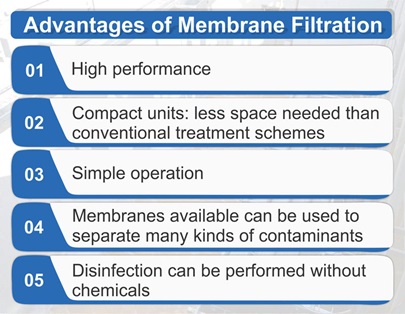

What are the advantages of membrane filtration in water treatment?

The advantages include:

· extreme performance

· compact units require less space than traditional treatment methods

· easy operation

· numerous types of pollutants can be separated using the available membranes

· it is possible to disinfect without using chemicals

What are the disadvantages of membrane filtration in water treatment?

Some disadvantages include:

· creation of contaminated water from backwashing

· regular membrane replacement and maintenance is required

Types of membranes as per their structure

Traditional membranes come in different primary categories. Some of these include:

· Plate and frame membrane

The flat sheet membrane, two end plates, and spacers make up this structure, which is the simplest. The membrane is frequently on the inside of a tube in tubular modules, and the feed solution is pumped through the tube.

· Spiral wound membrane

The spiral wound module is the most often used in the industry for nanofiltration or reverse osmosis membranes. This module has a perforated permeate collection tube covered in a flat sheet membrane.

On one side of the membrane, the feed flows. On the other side of the membrane, permeate is gathered and spirals inward towards the central collection tube.

· Fine hollow fibre membranes

Bundles of hollow fibres are placed in a pressure vessel to form the hollow fibre modules, used for seawater desalination. They may have a shell-side feed configuration, in which the feed exits the fibre ends after travelling along the outside of the fibres. In a bore-side feed design, where the feed is cycled via the fibers, hollow fibre modules can also be employed.

Pressure vessels don't always use the hollow fibres used in membrane bioreactors and wastewater treatment. The permeate can be collected from one end of fibre bundles that have been suspended in the feed solution.

· Tubular membranes

Micro-porous coatings of PVDF or PES are applied to the inside or outside walls of porous tubes, with inner diameters ranging from 5 mm to 15 mm.

Tubular modules, which are made of individual tubular membranes fitted into a cylindrical housing, can operate in either outside-in (waste water stream flows outside individual tubes), or inside-out (waste water stream flows inside individual tubes) configurations, depending on the orientation of the micro-porous layer.

· Vibratory membranes

The main distinction from conventional membranes is that this membrane's basic structure is vertical rather than horizontal, which results in a less area requirement per unit than for other separation techniques. Vibratory membranes or VR were created a while ago to address the most prevalent issue with membranes, which is the scaling brought on by the residue layers, which build up on the membrane's surface during the filtration process.

Any sort of wastewater can be filtered by these vibrating membranes, which can also handle effluents with a high solids load. Additionally, it is a technique that does not require chemicals for operation, with the exception of those required for routine membrane cleaning.

Working of vibratory membranes

The liquid that needs to be treated in a VR Membranes system circulates slowly, between the components of the parallel membranes, making it nearly immobile. By aggressively vibrating the membrane components in a direction, tangential to the membrane surface, the shear's cleaning action is produced.

The solids are forced to rise to the membrane's surface and are once again mixed with the substance or effluent, which is moving through the membrane as a result of the shear waves created by the membrane's vibration. Due to the membrane's pores being cleaned by the severe shear, it performs better than usual membranes.

Learn more about our options for treating water with the use of membranes

Contaminated water is harmful to the environment and to people's health. To prevent water pollution, poisonous and dangerous substances that are released into the water must be eliminated.

We provide various water treatment solutions for any sector with high-quality, dependable products and a knowledgeable engineering group, such as Commercial RO Plants, Industrial RO Plants, Water Softeners, DM Plants, EDI plants, etc. To find out more about our alternatives for treating water, get in touch with us. Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.