What is meant by Activated carbon filtration?

The use of carbon in the form of charcoal has been used since antiquity for many applications. In Hindu documents dating back to 450 BC, we can find mention of charcoal filters for the treatment of water.

Charred wood, bones and coconut charcoals were used during the 18th and 19th century by the sugar industry for decolourising solutions. Activated carbon is prepared in such a way that it exhibits a high degree of porosity and an extended surface area.

Structure of a typical carbon-

A typical carbon particle has numerous pores that provide a large surface area for water treatment.

How carbon aids in filtration?

During filtration of water with activated carbon, impurities either adhere to the surface of these carbon granules or are trapped in the small pores of the activated carbon. This process is called adsorption.

Activated carbon filters efficiently remove certain organics (such as unwanted taste and odours, micro-pollutants), chlorine, fluorine or radon, from drinking water or wastewater. But it is not effective for microbial contaminants, metals, nitrates and other inorganic contaminants, which makes disinfection an important process after activated carbon treatment.

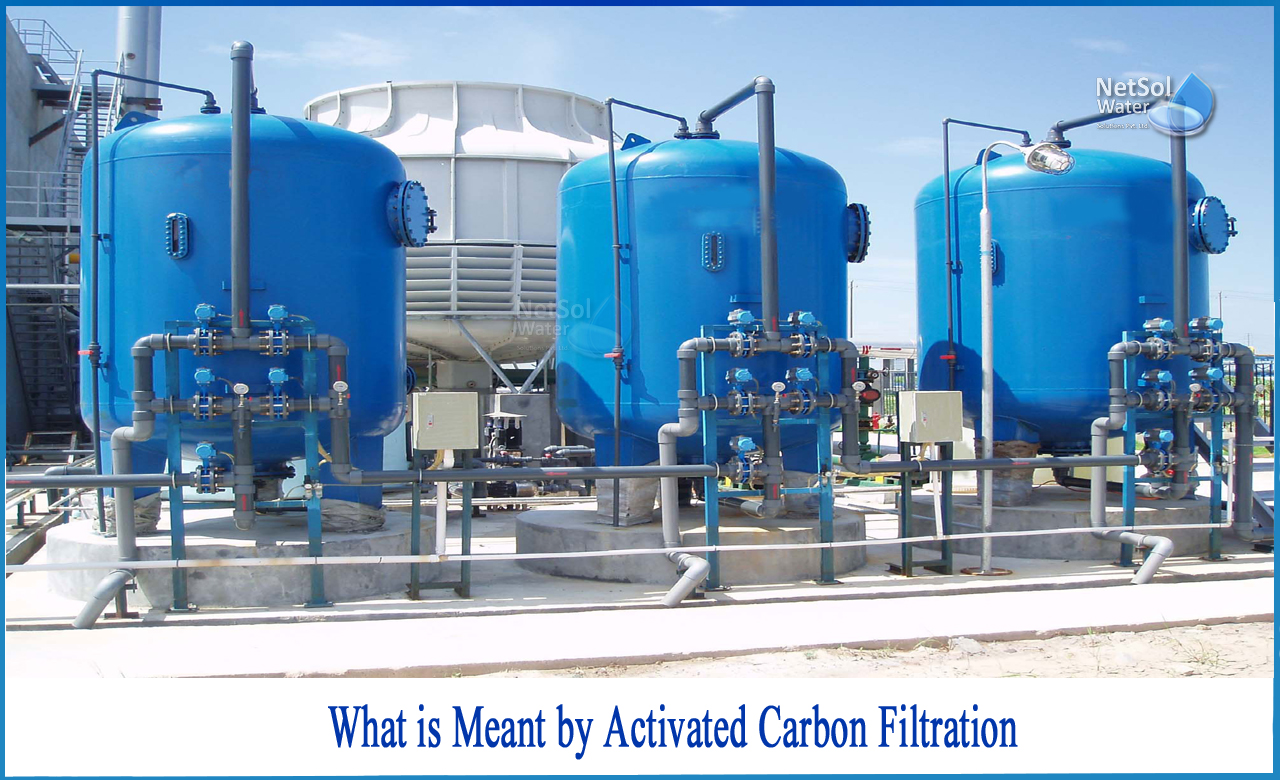

Activated carbon filtration is used in centralized treatment plants and at household levels, to produce drinking water and in industries to treat effluents. It is also an upcoming treatment process for the removal of micro-pollutants both in drinking water production and for the purification of treated wastewater before effluent discharge.

Treatment principles

There are two types of water filters: particulate filters and adsorptive/reactive filters.

Particulate filters remove particles by size, and adsorptive/reactive filters contain a material that either adsorbs or reacts with a contaminant present in water.

The principles of adsorptive activated carbon filtration is same as those of any other adsorption material. The contaminant is attracted to and held (adsorbed) on the surface of the carbon particles. The characteristics of the carbon material (particle and pore size, surface area, surface chemistry, etc.) influence the efficiency of adsorption.

Activated carbon filtration depends upon the following parameters

1: The characteristics of the chemical contaminant are important. Compounds that are less water soluble are more likely to be adsorbed to a solid.

2: A second characteristic is the affinity that a given contaminant has with the carbon surface. This affinity depends on the charge and lower the charge, the higher the affinity of contaminant with carbon.

3: When multiple compounds are present in water, more adsorbents with stronger adsorptive power will adhere to carbon than those with relatively weaker adsorptive power.

Preparation of activated carbon

The medium of the activated carbon filter is usually petroleum coke, bituminous coal, lignite, wood products, coconut shells, or peanut shells. Carbon media are "activated" by exposure to high temperature (800-1000° C) streams (gas such as water, argon, nitrogen), which normally do not contain oxygen.

In some cases, carbon can be pickled or coated with a compound to enhance the removal of certain contaminants. Activation produces carbon with many pores and a high specific surface area. It is then ground to produce a granular or powdered carbon product.

What is Point Of Entry and Point of Use treatment of Activated Carbon?

The activated carbon system is often used to remove organic substances (odours, trace pollutants) from drinking water at centralized and dispersed levels. At the central level, these are usually one of the last steps before water is supplied to the distribution network.

At the distributed level, the activated carbon filtration unit can be either a point of use (POU) or point of entry (POE) treatment.

Activated carbon filters can also be used as a tertiary treatment in wastewater treatment plants to remove micro-pollutants from municipal effluents or recalcitrant contaminants from industrial effluents.

Combination of activated carbon and other processes

Activated carbon is often used as a pre-treatment to protect other water treatment equipment’s such as reverse osmosis membranes and ion exchange resins from potential damage from oxidation and organic fouling.

The combination of ozone treatment and activated carbon is a very efficient method for removing organic matter, including trace pollutants. In addition, the life of activated carbon filters combined with ozone is significantly extended and operating costs are significantly reduced.

Conclusion

The use of activated carbon filtration is very old technique for water filtration and in modern era, we have modified its use and understood the mechanism of treatment. This has led us to enhance the efficiency of the treatment procedure.

How can Netsol Water help?

Many aeration technologies are currently available in the market, and each is designed to address a specific challenge or range of challenges.

We are India’s leading water and wastewater treatment solution company which covers all the needs of any water treatment scheme on all levels. We have the expertise to provide wastewater solutions at domestic, industrial and municipal levels including various Aeration devices.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.