What is Inorganic membranes and its application?

Inorganic membranes are a class of membrane materials that are composed of inorganic substances such as ceramics, metals, and metal oxides. These membranes offer unique properties such as high thermal stability, chemical resistance, and mechanical strength, making them suitable for various separation and filtration applications.

In this blog, we will explore inorganic membranes in detail, including their structures, working principles, and common applications.

Structure of Inorganic Membranes:

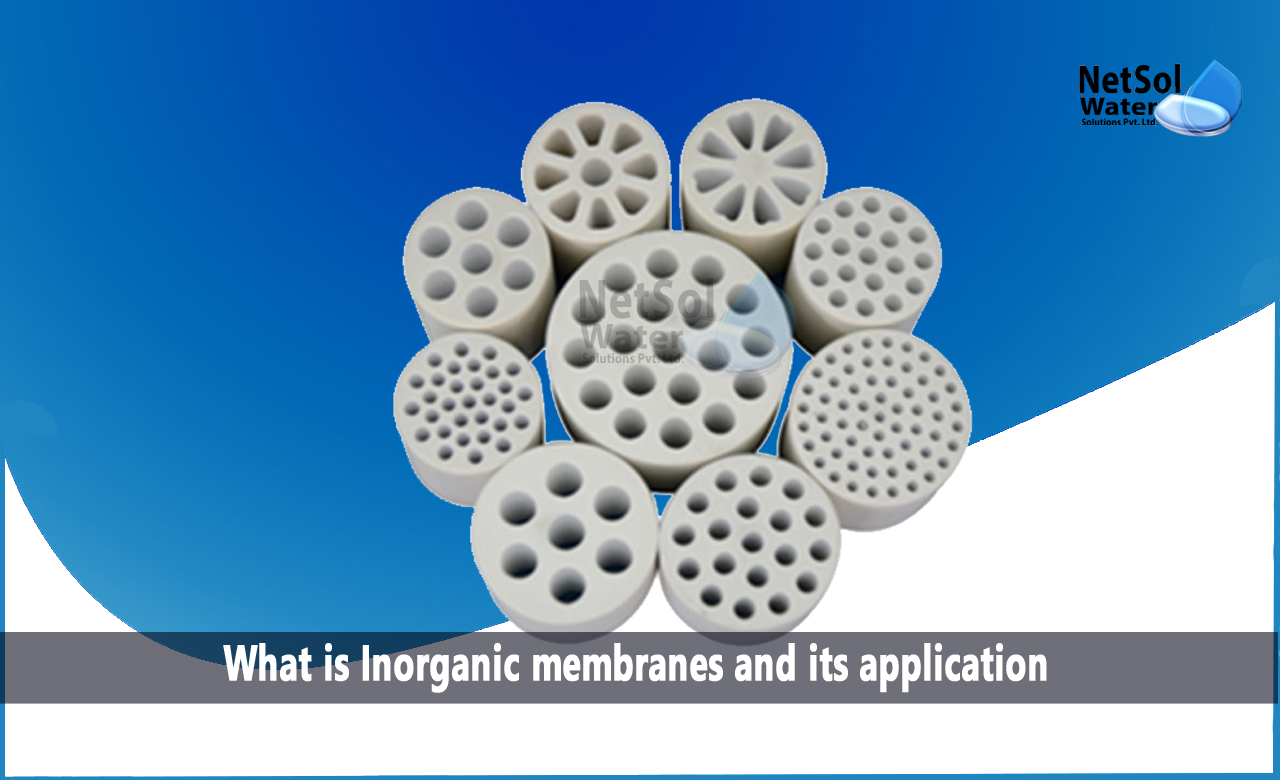

Inorganic membranes possess a dense or porous structure depending on the specific application and separation requirements. The structure of inorganic membranes can be categorized into the following types:

1. Dense Membranes: Dense inorganic membranes have a nonporous structure and are often used for gas separation applications. These membranes allow the selective transport of specific gas molecules while blocking others based on factors such as molecule size, shape, and solubility.

2. Porous Membranes: Porous inorganic membranes consist of a network of interconnected pores that allow the passage of certain molecules or ions based on their size. The pore size and distribution can be tailored to achieve desired separation characteristics. Porous membranes are commonly used in liquid filtration and separation processes.

Working Principles of Inorganic Membranes:

The working principles of inorganic membranes depend on their specific structure and separation mechanism. However, the general working principles can be summarized as follows:

1. Size Exclusion:

Inorganic membranes with uniform pore sizes, such as ceramic membranes and zeolite membranes, rely on size exclusion to separate molecules based on their molecular size. Smaller molecules or ions can pass through the pores, while larger molecules are retained.

2. Adsorption:

Inorganic membranes with a porous structure and surface modifications can exhibit adsorption properties. They can selectively adsorb certain molecules or ions onto their surface while allowing others to pass through. Adsorption-based inorganic membranes are commonly used in water treatment and removal of contaminants.

3. Solution-Diffusion:

Some inorganic membranes, particularly dense membranes, utilize a solution-diffusion mechanism for separation. This involves the dissolution of specific molecules in the membrane followed by diffusion through the membrane matrix. The selectivity is determined by the solubility and diffusion rates of the molecules in the membrane material.

Common Applications of Inorganic Membranes:

1. Gas Separation: Inorganic membranes are widely used for gas separation applications, including the separation and purification of gases. Some common applications include:

· Hydrogen Separation: Inorganic membranes, particularly metal membranes and metal oxide membranes, are utilized for the separation and purification of hydrogen gas. These membranes selectively allow hydrogen to pass through while blocking other gases, enabling the production of high-purity hydrogen for various industries, such as fuel cell applications and ammonia production.

· Oxygen Enrichment: Inorganic membranes, such as ceramic membranes, are employed for oxygen enrichment processes. These membranes selectively transport oxygen from air or gas mixtures, allowing the generation of oxygen-enriched streams for medical applications, oxy-fuel combustion, and wastewater treatment.

· Carbon Dioxide Capture: Inorganic membranes, especially ceramic and metal oxide membranes, are used for carbon dioxide capture from flue gas or industrial exhaust streams. These membranes allow the selective permeation of carbon dioxide, enabling its separation for storage or utilization in various industries, such as enhanced oil recovery and carbon dioxide-based chemical processes.

2. Water Treatment: Inorganic membranes play a vital role in water treatment processes, providing solutions for various applications:

· Microfiltration and Ultrafiltration: Ceramic membranes are commonly employed for microfiltration (MF) and ultrafiltration (UF) processes in water treatment. These membranes effectively remove suspended solids, bacteria, and larger particles, providing clarification and pre-treatment of water sources for further purification.

· Nanofiltration and Reverse Osmosis: Inorganic membranes, including ceramic and metal oxide membranes, are used for nanofiltration (NF) and reverse osmosis (RO) processes. These membranes remove smaller particles, ions, and dissolved contaminants, enabling the production of high-quality drinking water, desalination of seawater or brackish water, and treatment of industrial wastewater.

3. Catalysis and Chemical Reactions: Inorganic membranes find applications in catalytic processes and chemical reactions:

· Catalytic Membrane Reactors: Inorganic membranes with catalytic properties are utilized in membrane reactors, where reactions occur directly on the membrane surface or within the membrane pores. These membrane reactors offer enhanced selectivity, improved conversion rates, and simplified separation processes in various chemical reactions, such as hydrogenation, dehydrogenation, and oxidation reactions.

4. Environmental Remediation: Inorganic membranes are employed in environmental remediation processes to treat contaminated water and wastewater:

· Heavy Metal Removal: Inorganic membranes, particularly ceramic membranes, are used for the removal of heavy metals from industrial wastewater and contaminated groundwater. These membranes can selectively adsorb or separate heavy metal ions, helping in the remediation of polluted water sources and meeting regulatory requirements.

· Nutrient Stripping: Inorganic membranes, such as ceramic and metal oxide membranes, are employed for nutrient stripping processes, particularly in the treatment of wastewater from agricultural or industrial sources. These membranes selectively remove nutrients such as nitrogen and phosphorus, preventing eutrophication and improving water quality.

5. Industrial Filtration and Separation: Inorganic membranes find applications in various industrial filtration and separation processes:

· Solid-Liquid Separation: Inorganic membranes, including ceramic membranes, are used for solid-liquid separation applications in industries such as pharmaceuticals, biotechnology, and food and beverage. These membranes effectively remove particles, colloids, and microorganisms, providing clear and purified liquids for further processing.

· Oil-Water Separation: Inorganic membranes, such as ceramic membranes, are utilized for oil-water separation in industries like petrochemicals, oil and gas, and wastewater treatment. These membranes facilitate the separation of oil or hydrocarbon contaminants from water, allowing the recovery of valuable resources and minimizing environmental impact.

6. Biotechnology and Pharmaceuticals: Inorganic membranes are utilized in biotechnology and pharmaceutical industries for various applications:

· Protein Separation and Purification: Inorganic membranes, particularly ceramic membranes, are employed for protein separation and purification processes. These membranes can selectively retain or separate proteins based on their size, charge, and other properties, enabling the production of purified proteins for pharmaceuticals, biopharmaceuticals, and diagnostic applications.

· Bioreactors and Cell Culture: Inorganic membranes are used in bioreactors and cell culture systems for cell retention and biomass separation. These membranes enable the continuous operation of bioreactors by retaining cells within the reactor while allowing the passage of nutrients and products, facilitating efficient and cost-effective bioprocesses.

· Virus Filtration: Inorganic membranes with precise pore sizes are utilized for virus filtration in pharmaceutical manufacturing and biotechnology processes. These membranes effectively remove viruses from process streams, ensuring the safety and purity of final pharmaceutical products.

7. Energy Storage and Conversion: Inorganic membranes play a role in energy storage and conversion technologies:

· Fuel Cells: Inorganic membranes, such as ceramic and metal oxide membranes, are used as electrolyte membranes in fuel cells. These membranes enable the selective transport of ions, facilitating the conversion of chemical energy into electrical energy in fuel cell systems.

· Batteries and Energy Storage: Inorganic membranes are employed in batteries and energy storage devices for ion transport and separation. These membranes help in maintaining the integrity of electrochemical systems and preventing cross-contamination between different cell components.

8. Gas and Liquid Filtration in Industrial Processes: Inorganic membranes find applications in various industrial processes for gas and liquid filtration:

· Chemical Process Filtration: Inorganic membranes are used in chemical process industries for the filtration and separation of chemical compounds, catalyst recovery, and purification of process streams.

· Food and Beverage Processing: Inorganic membranes, such as ceramic membranes, are utilized in the food and beverage industry for the filtration and separation of liquids, removal of particulates, and clarification of beverages.

· Pharmaceuticals and Personal Care: Inorganic membranes are employed in pharmaceutical and personal care industries for the filtration and separation of liquids, removal of particles, and purification of active ingredients.

Conclusion:

Inorganic membranes offer a wide range of applications across various industries. Their unique properties, such as high thermal stability, chemical resistance, and precise pore size control, make them valuable for separation, filtration, and purification processes. From gas separation and water treatment to catalysis and environmental remediation, inorganic membranes contribute to efficient and sustainable processes in industries such as energy, water, pharmaceuticals, biotechnology, and more. Continued research and development in inorganic membrane materials and technologies are expected to further expand their applications and improve their performance in the future.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com