What is Imhoff tank and its uses?

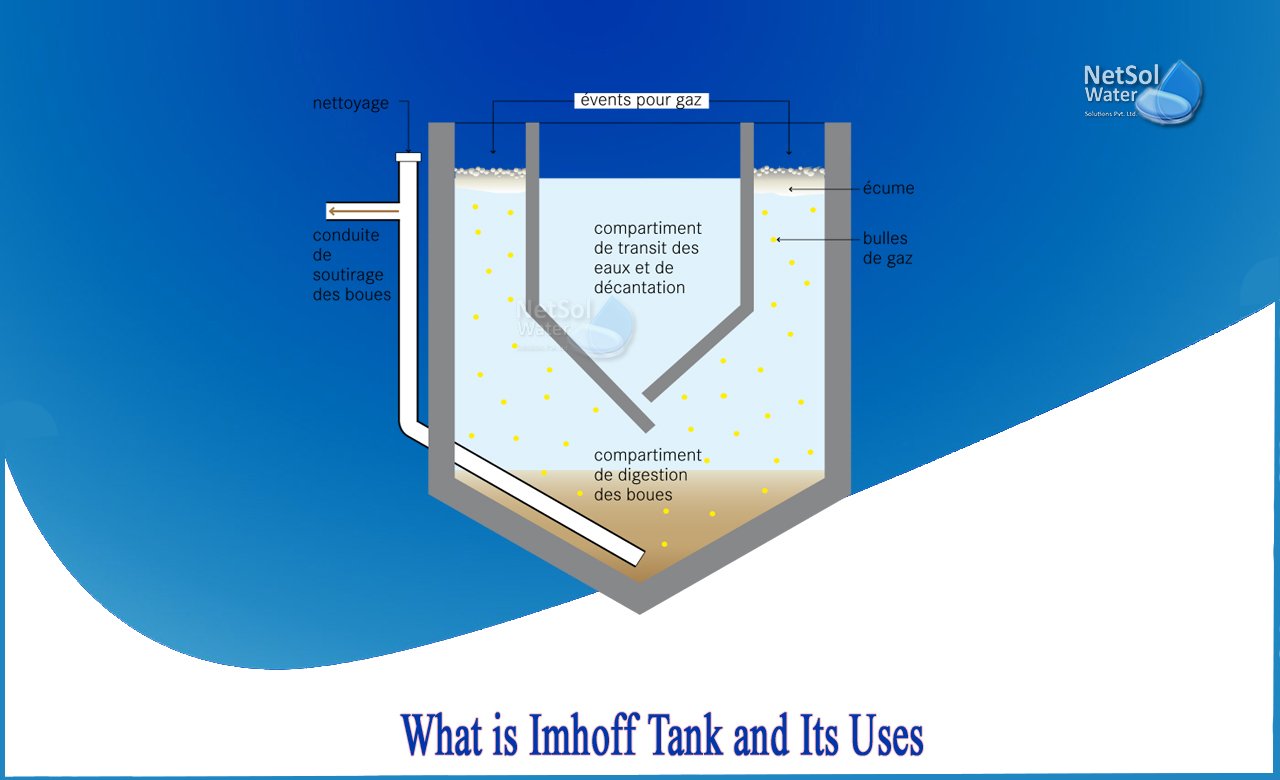

The Imhoff Basin (named after the German engineer Karl Imhoff) consists of two chambers: An upper sedimentary zone and a lower sedimentary and sludge decay zone.

Depending on the dimensions and climatic conditions, suspended solids can be reduced by 50-70%, COD can be reduced by 25-50%, and sludge can be well stabilized. This is an example of a simple, compact, and effective system for urban sewage treatment.

The tank can be cylindrical or parallelepiped in shape. A settling zone with a typical V-shaped wall has a slot at the bottom that allows solids to settle in the digestion chamber. The system also prevents the gas produced by the anaerobic reaction from returning to the surface and interfering with the sedimentation process. The gas produced in the digestion chamber drags sludge particles from the bottom of the water to the surface, creating a top layer of foam that needs to be removed on a regular basis. Sludge is collected in a digestive tub where it is subjected to an anaerobic process and partially stabilized. The liquid fraction remains in the tank for only a few hours (3.5-7 hours). This allows you to get (not septic tank) final drain.

The solids stay in the chamber digestion for much longer under uniform and controlled conditions that ensure good thickening. Biogas production is higher than septic tanks and requires a proper ventilation system to avoid the problem of foul odours. Wastewater may permeate the soil (according to local regulations) or may require post-treatment (e.g., activated sludge, drip filters, artificial wetlands, etc.).

How does Imhoff tank work?

The Imhoff Basin is a two-story purification basin consisting of a sedimentation chamber at the top and a sludge digestion chamber at the bottom. Both vent and foam accumulation zones are on the sides of the sand basin. Normally, the water pressure retention time is shorter than that of septic tanks (3 to 7 hours), and it can maintain aerobic conditions in wastewater.

T-shaped pipes or baffles are used to slow down water and prevent light liquids from dragging. The bottom of the settling tank usually has an inclination of 50 ° to 60 ° and a slot should be created between the two chambers to prevent the gas from rising in the settling unit. With larger solutions, the walls of the digestive sludge chamber reach an inclination of about 45 °, where the sludge slides into the centre, where it can be removed more easily.

The dimensions of the anaerobic digestion mainly depend on the population supplied, the degree of sludge stabilization, the frequency of cleaning, and the amount of sludge produced in relation to weather conditions (temperature).

Digestion chambers are generally designed with a sludge storage capacity of 6-12 months in mind to allow for a sufficient anaerobic process. In cold climates, long residence times need to be considered to achieve comparable sludge stabilization, resulting in higher quantities. Wastewater is stable enough and almost odourless, so choose the Imhoff basin as a pre-treatment, especially if other processes are in contact with the external environment (phytoremediation, wetlands, surface water, etc.).

What are the benefits of Imhoff tank?

Sedimentation and digestion into a single unit.

- Resistance polluting peak input.

- Small footprint.

- Fresh effluent (aerobic conditions, not septic, less odour).

- Low operating costs.

- Simple operation and maintenance.

- No energy consumption related to the operation.

What are some the disadvantages?

- Greater height or depth compared to other solutions.

- Low pathogens reduction.

- Periodic operation by specialized companies.

- Risk of occlusion of slot between two compartments.

- Odour problems if not properly connected to vents.

- Sludge disposal.

More complex than septic tank.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.