What is Food to Mass (F/M) ratio?

The food-to-microorganism (F/M) ratio, which can be measured, is an important factor in the design and operation of aeration basins such as activated sludge basins.

The sludge age, which governs the mass of sludge to be wasted daily from the system, is a critical parameter in the design and control of the activated sludge system. The sludge age should completely replace the Food to Microorganism ratio (F/M, kg BOD or COD load per day per kg MLSS or MLVSS in reactor) as a reference and control parameter, especially if nitrification is required.

The relationship between the load (i.e. kg/day as opposed to mg/l) of BOD (or bacterial 'food') entering the aeration plant and the 'mass' of bacteria in the aeration tank available to treat the entered BOD is one of the most fundamental control parameters for the activated sludge process. As a result, this is known as the Food to Mass Ratio (F/M ratio), also known as the Sludge Loading Rate (SLR).

The amount of biomass contained within the reactor is referred to as the Mixed Liquor Suspended Solids (MLSS).

The loading measured as BOD-5 is referred to as FB: M, as opposed to FC: M, which is when COD is the measured parameter. This critical ratio, defined as the kg of BOD-5 applied per kg MLSS per day, is perhaps the single most important parameter in controlling the activated sludge process.

Just to function properly, the activated sludge process requires a balance between the food entering the bioreactor and the microorganisms in the bioreactor.

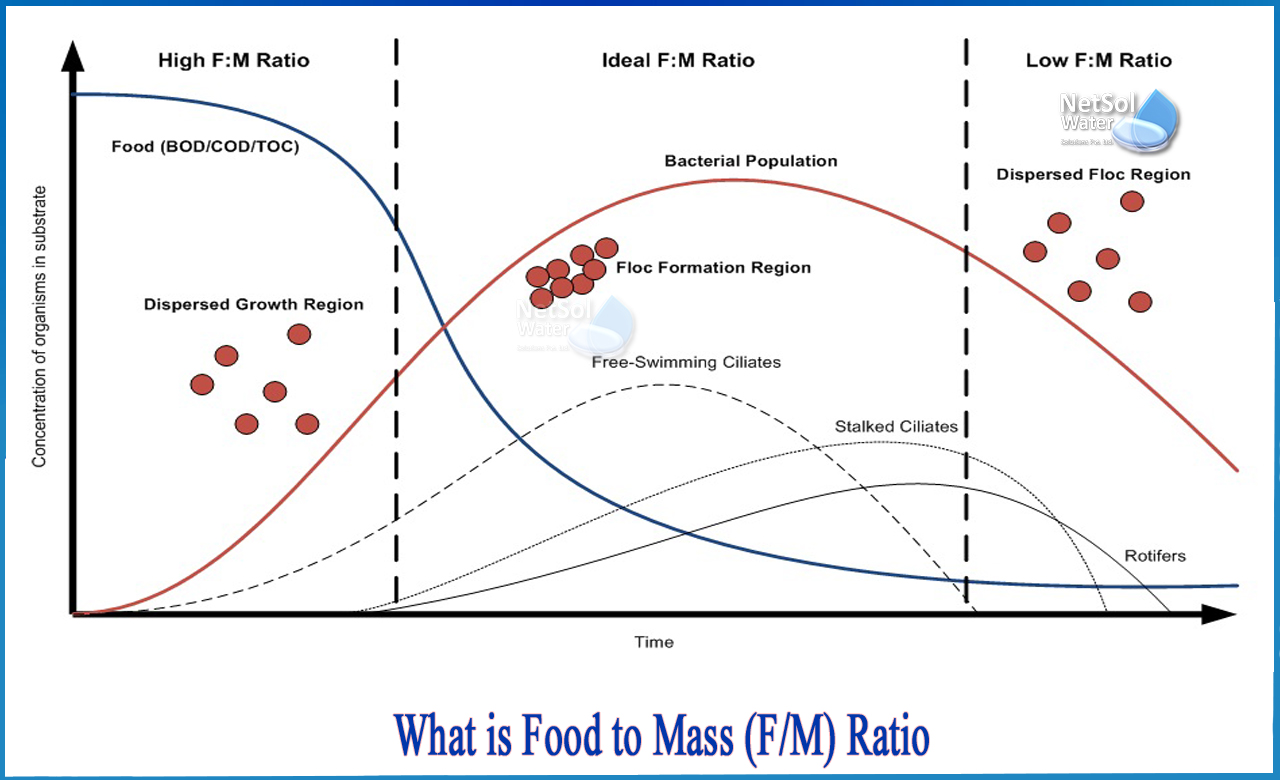

A high F: M ratio indicates that there is more food (measured as BOD, COD, or TOC) than microorganisms available to consume that food. In suspended growth bioreactors, when the F:M ratio is high, the bacteria are active and multiply quickly, but they are also more dispersed. A high F:M ratio, as a result of this dispersion, creates an environment in which the bacteria will not form a good, large, dense floc. As a result, a high F:M ratio frequently leads to the poor settling sludge in the secondary clarifier and turbid effluent.

A low F:M ratio indicates that there are many microorganisms but only a limited amount of food. Only when food is scarce, bacteria begin to form a thicker slime layer, lose motility, and clump together to form a dense floc that settles well in the clarifier.

Two quantities are required to calculate the F:M ratio:

1) Kilogrammes of organic material entering the bioreactor and

2) Kilogrammes of microorganisms in the bioreactor.

The organic load, or food, is calculated using the five-day biochemical oxygen demand (BOD-5) concentration, and the microorganism concentration is calculated using the mixed liquor volatile suspended solids (MLVSS) concentration.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.