What is foaming in Aeration Tanks?

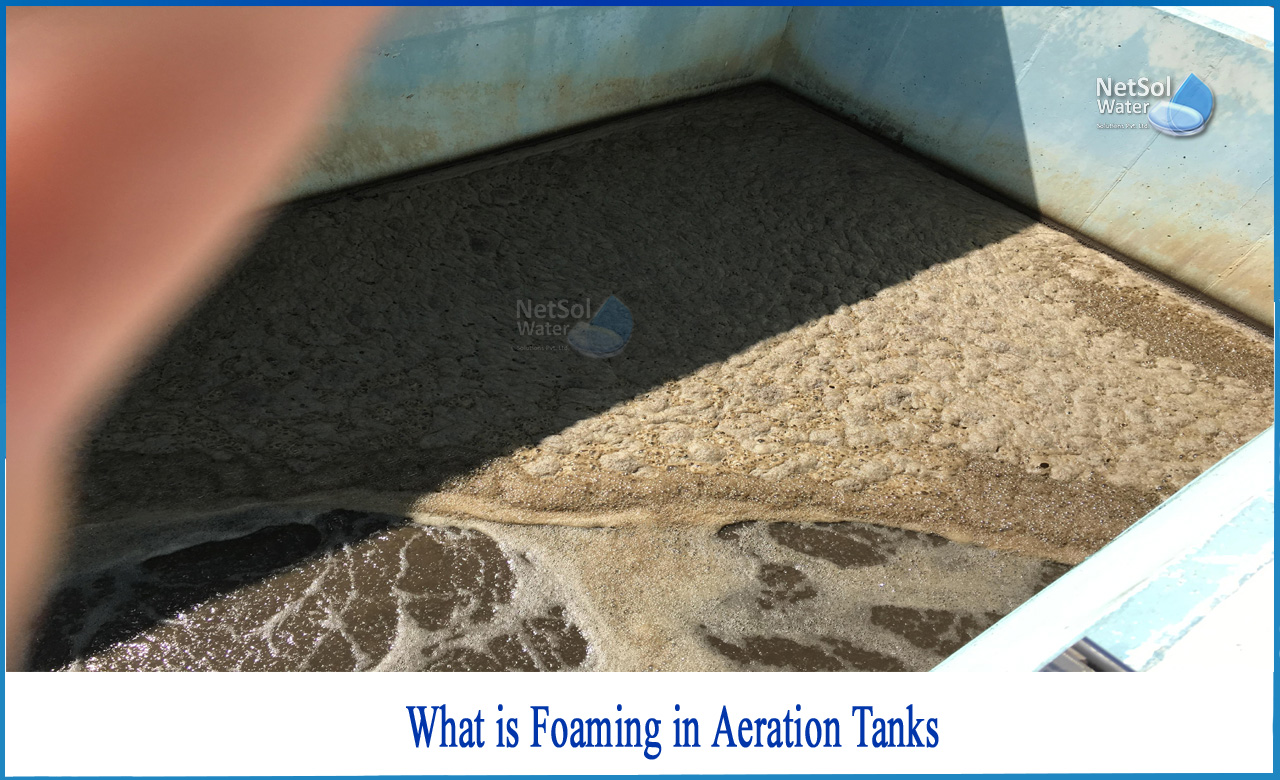

Foam is a gaseous mass formed on the surface of a liquid, such as the froth. There are various variables that can generate foaming in activated sludge. Foaming can be caused by operational or non-operational issues.

Most Operations employees’ believe that foam on the surface of an aeration basin indicates the presence of Nocardia; nevertheless, the foam does not appear on the surface of all plants due to Nocardia. Some may have too many or too few solids, as well as a low D.O.

Types of foams

1: Normal Activated Sludge Foam:Normal activated sludge is light tan in colour and covers anywhere from 10% to 25% of the tanks surface. The bubbles on the surface dissolve shortly.

2: Stiff White Foam:A new plant or an overloaded plant will usually have stiff white, billowing froth, indicating a juvenile sludge (low MCRT).

3: Heavy Brown Foam: Sludge re-aeration plants typically produce a thick, black scummy foam. The scummy, black foam suggests older sludge, which might cause other issues, downstream of the aeration tank. There's also a chance that Nocardia is present in the sludge.

What are the causes of the Stiff White Foam?

Young sludge (low MCRT) is found in either a new or overloaded facility, as evidenced by stiff white, billowing froth. This indicates a low MLSS content and a high FM concentration.

The following are some possible reasons of a firm white foam:

- Sludge that has been activated is not being returned to the aeration tank.

- Low MLSS as a result of the process's inception.

- Low MLSS for present organic loading due to severe sludge waste or a large organic load from an industry. Weekends are the busiest times.

- Toxic circumstances (pH below 6.5 or over 9.0), insufficient DO, nutritional shortages, or seasonal (winter/summer) temperatures in the activated sludge systems.

- Inadvertent solids loss from the secondary clarifier.

- Hydraulic loads that are too high or too sudden.

- Biological Disturbance.

- Solids washout due to a high sludge blanket in the secondary clarifier.

- Defects in the secondary clarifier's mechanical components (leaking seals, open de-watering valves).

- Inadequate flow or solids loading distribution to various clarifiers.

What are the causes of the Brown Foam?

These foams are typically found in plants that operate at a low loading range. Plants that are designed to nitrify and are in the nitrification mode produce low to moderate volumes of dark brown foam. Plants with filamentous organisms, such as Nocardia, produce a thick, oily dark tan foam that drips into the clarifier's surface. Filamentous organism-containing scum should be discarded rather than restored to the aeration tank. When functioning in the re-aeration mode of operation, a thick dark brown greasy foam is typical. Thick, dark brown foam indicates ancient sludge (high MCRT) and can cause extra problems in the clarifier by accumulating behind the influent baffles and causing a scum disposal issue.

Excessive Brown Foaming can be caused by a variety of factors, including the following:

- The aeration tank is being run at a low FM, since the regulatory agency requires nitrification.

- As a result of insufficient sludge waste, a high MLSS concentration develops. When wastewater temperatures shift between the winter and summer seasons, this situation might emerge unintentionally, affecting microbial growth and activity.

- Sludge re-aeration mode is active.

- Inadequate waste management programme.

Operational Considerations to control Foaming-

1: Chemical Addition: Chemicals can be used to assist manage foam, but great attention must be paid to the procedure or it could have negative consequences.

2: Antifoaming agents: Because biological foams are significantly more stable than the foams against which commercial antifoams were created, using antifoaming agents is a relatively expensive and risky strategy.

3: Skimming Foam: Skimming the foam to a location where it can be disposed of would be beneficial.

4: Water sprays: When appropriately positioned in the right areas, water sprays can aid in the fight against the foam. A sprinkler in the aeration basin may also be beneficial.

5: Surface and submerged overflows: Foam can be prevented from exiting the secondary clarifier by using submerged aeration basin gates. This makes it much more difficult to get rid of foam. Surface overflows from the aeration basin can aid in the transport of foam to the secondary clarifier, where it is skimmed off the top.

If you want to know more about foaming in aeration tanks, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.