What is Filtration process in Sewage Treatment Plants (STP’s)?

A sewage treatment plant works by circulating air in order to stimulate bacteria to multiply and break down sewage. The goal is to produce effluent that is cleaner and environmentally friendly. Sewage treatment plants can be used to treat the wastewater produced by commercial as well as domestic households.

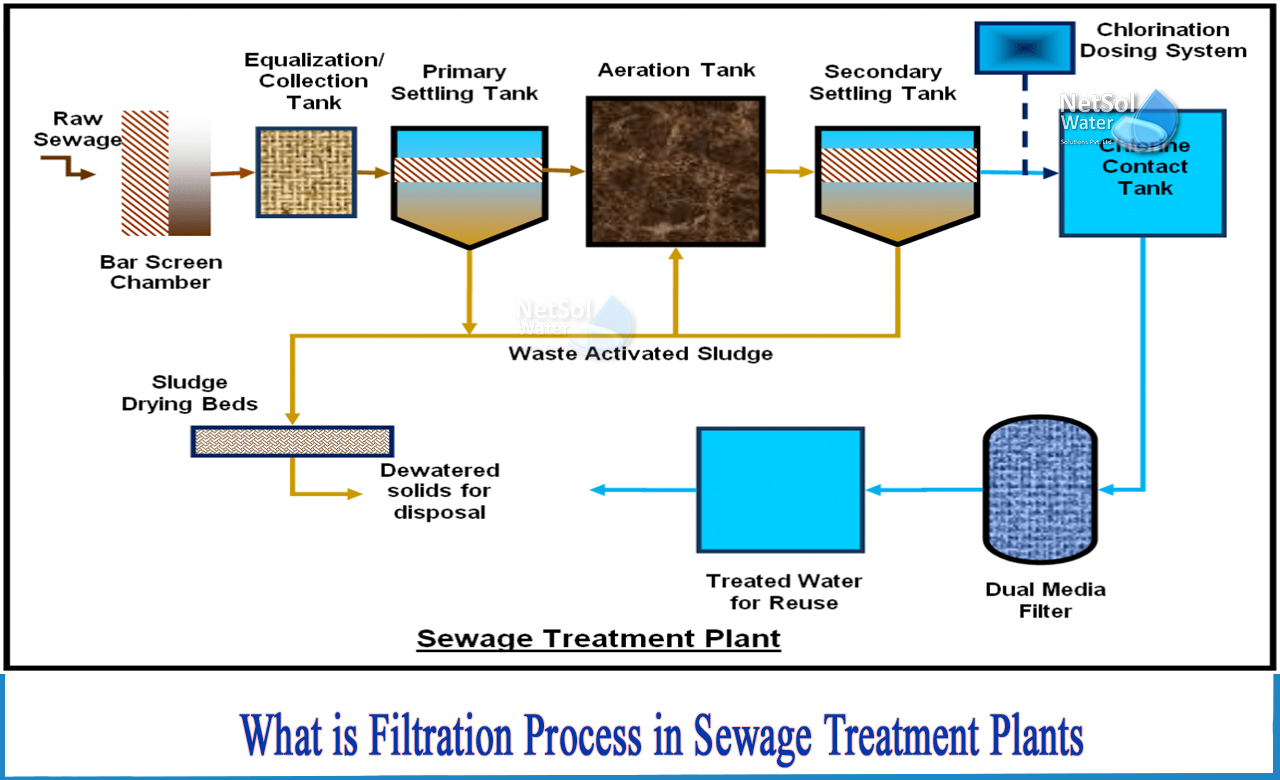

Stages involved in Sewage Treatment Plant:

1. Screening

The first step in the wastewater treatment process is screening. Large materials such as diapers, nappies, and even broken bottles, bottle caps, plastics, and rags that could impede or harm equipment are removed during screening.

2. Primary Treatment

Separation of solid, organic matter from wastewater is required. It is accomplished by placing wastewater in big settlement tanks and allowing the solids to settle to the bottom. Large scrappers scrape the tank floor continuously at the bottom of these circular tanks, pushing the sludge to the center, where it is pumped away for further treatment. The remaining water is pumped to a secondary treatment facility.

3. Secondary Treatments

At this point, the water is pumped into big rectangular tanks. In order to enable microorganisms to break down the microscopic particles of sludge that escaped the sludge scraping process, air is pushed into the water.

4. Final Treatment

After that, the water is pumped through a settling tank. More sludge is created at the bottom of the tank due to the bacterial activities settling. Sludge is scraped and collected once more for treatment. At this point, the water is nearly devoid of hazardous compounds and pollutants. Water is allowed to run over a wall before being filtered through a sand bed to remove any remaining particles.

Types of filtrationin Sewage Treatment Plant:

The technique of removing particles and other media of a given size and larger from liquids is known as liquid filtration. When these particles are removed from a wastewater system, the water can be reused within the system. This form of filtration is necessary for a variety of reasons.

The two main forms of filtration used in wastewater treatment systems are:

1. Particle filtration

Particle filtration is a system that uses physical or mechanical ways to separate particulates from liquids. Particle filtration is often one of the initial steps in the treatment of contaminated wastewater when it comes to wastewater treatment.

For particle filtering, there are three common filter types:

a. Bag Filters

Bag filters are an excellent choice for smaller applications and systems where waste reduction is a priority. Wastewater is pumped into the bag, which traps the solid particles in the water, enabling only clean water to pass through the pores to the other side.

b. Cartridge Filters

Cartridge filters are a modular form of filter that uses pleated fabric or another type of screen to catch particles and even chemicals throughout the filtration process.

c. Self-cleaning filters

The ability of these filters to clean themselves is widely regarded as one of the most helpful features of these filters. Self-cleaning filters are perfect for systems that can't be turned off for maintenance.

2. Membrane Filtration

When particle filtration alone is insufficient for water reuse, membrane filtration is typically utilized. Depending on the final aim for the water, the treatment and processes necessary to process it can vary significantly. The more processes that must be utilized to make the water cleaner, the more processes that must be employed. Membrane filtering systems are commonly utilized when the best water quality is desired. Some of the commonly used membrane filters are:

a. Reverse osmosis

Filtering is indicated for applications that require the reduction or removal of dissolved solids. The reverse osmosis method also aids in the removal or reduction of extremely minute organic particles.

b. Ultrafiltration and microfiltration

Ultrafiltration and microfiltration are widely employed as a pre-treatment step before reverse osmosis. Water is forced through the tiny pores of the filter under low pressure during ultrafiltration. This technique aids in the removal of silt, organic debris with a high molecular weight, and even infections such as viruses.

Thus, when selecting a filter system for a certain application, a number of considerations must be considered. The filter's efficiency requirements, prospective changes in filter media, and the system's sterilization cycles are all factors to consider.

All these issues can be dealt by taking advice from professionals such as Netsol Water Solutions. We believe in giving complete set of solutions to all the problems.