What is double pass Reverse Osmosis system?

With a double pass reverse osmosis (DPRO) system, the permeate water is fed to a second reverse osmosis unit to produce purer water. With a one or two stage RO, the concentrate or reject stream is fed to a second RO system to produce water. A reverse osmosis system is used to purify the water by removing about 99% of all dissolved solids from the feed water. Single pass reverse osmosis systems produce product water (permeate) and reject water (concentrate) at the same time.

CHALLENGES

How does a double pass RO system work?

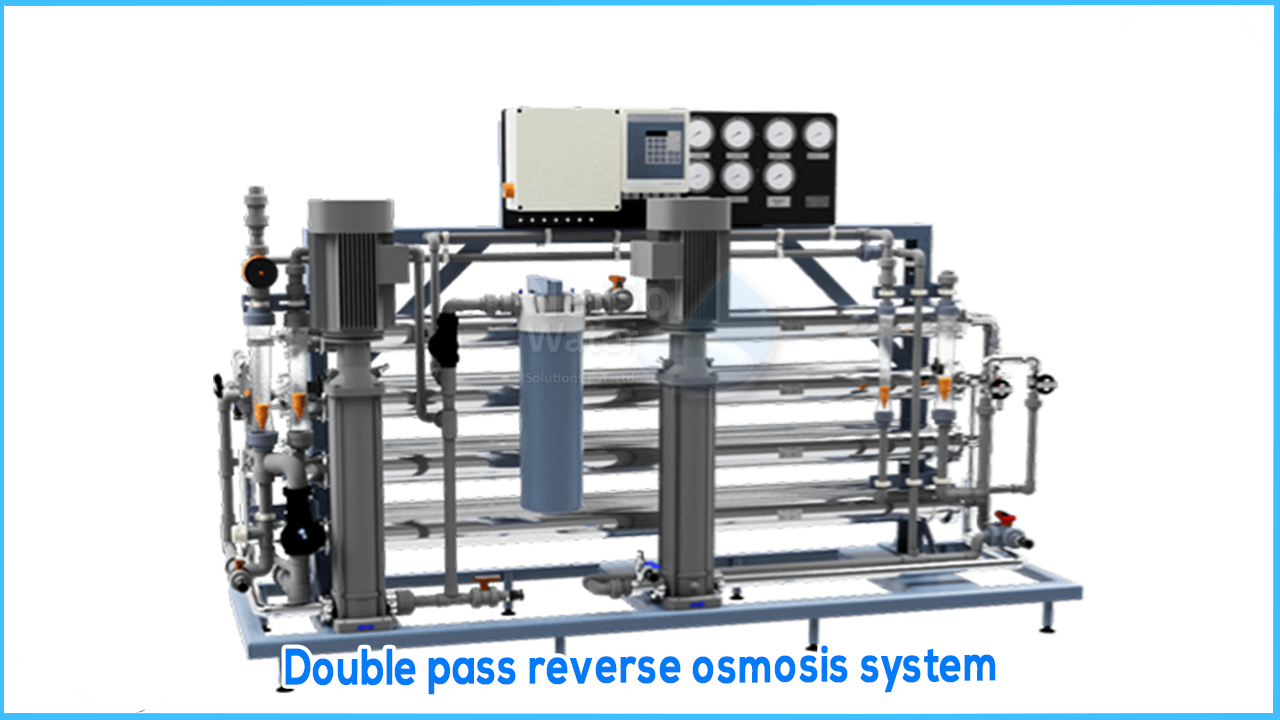

Two-Pass Reverse Osmosis Systems consist of two Reverse Osmosis systems (1st Pass and 2nd Pass), where the 1st pass has a higher volumetric flow capacity than the 2nd pass. In the middle there should be a rupture tank in which the permeate or concentrated water from the first RO step is stored and fed to the second step for subsequent filtration. In the case of water recovery, pre-treatment is required for both the 1st-pass and 2nd-pass RO systems, as the quality of the concentrated water in the 1st pass must approach the saturation point. On the other hand, an application may only require one pass pre-treatment when used as a permeate to feed the second pass.

SOLUTIONS

Why a two-step reverse osmosis system?

DPRO is used in most cases when the final permeate has a certain desired water quality required by the process equipment. It can be a combination of two brackish reverse osmosis systems, or a seawater reverse osmosis system followed by a brackish reverse osmosis system. Some farms are beginning to recycle water due to community pressure to minimize the use of city-supplied water or the extraction of water from raw sources, which dries up the aquifer in their area. These facilities use a DPRO system to increase the water efficiency of their systems. Due to their design, single pass reverse osmosis systems can only recover up to 80% of the feed water. Using a DPRO can increase water recovery to over 90%.

Many parts of the world face droughts and pressure to conserve water. A 2-step RO system can help minimize the generation of reject water. Some manufacturing facilities go a bit further by using the Zero Liquid Discharge plan by using a DPRO, evaporator or brine concentrator to separate salt from pure water in the final treatment phase and a salt crystallizer at the end. .

A mixed bed deionization (MBDI) system can also be used to polish the permeate water from the one-pass reverse osmosis system when the application is solely concerned with water quality. However, due to environmental concerns about hazardous chemicals needed to regenerate DI units, engineers specify the use of DPRO when the final water quality is within their requirements. An Electrode Ionization System (EDI) is a complementary water polishing system to the DPRO if the facility requires ultrapure water for advanced microchip or semiconductor fabrication applications.

BENEFITS

Our innovative dual-pass reverse osmosis system technology helps reduce dissolved solids by 99.9 percent while maximizing water recovery. Demineralized water is produced with a double pass reverse osmosis system to ensure a final conductivity of less than 5 µS / cm. This pure water is used to prepare the dialysate required for haemodialysis. Demineralized water must be not only chemically but also biologically high-purity. High quality is guaranteed by this ultrapure water treatment system with a solution that can be disinfected with hot water. The reverse osmosis system can be disinfected with hot water up to 80 ° C and guarantees high quality without the use of chemicals.

We at Netsol can make brackish water reverse osmosis systems on order in a double pass configuration.