Introduction

Different components of water treatment systems will contribute to operational and performance variation, in water and wastewater treatment systems. This variation may result from different treatment methods being used, the use of chemicals, or how much power the treatment methods need.

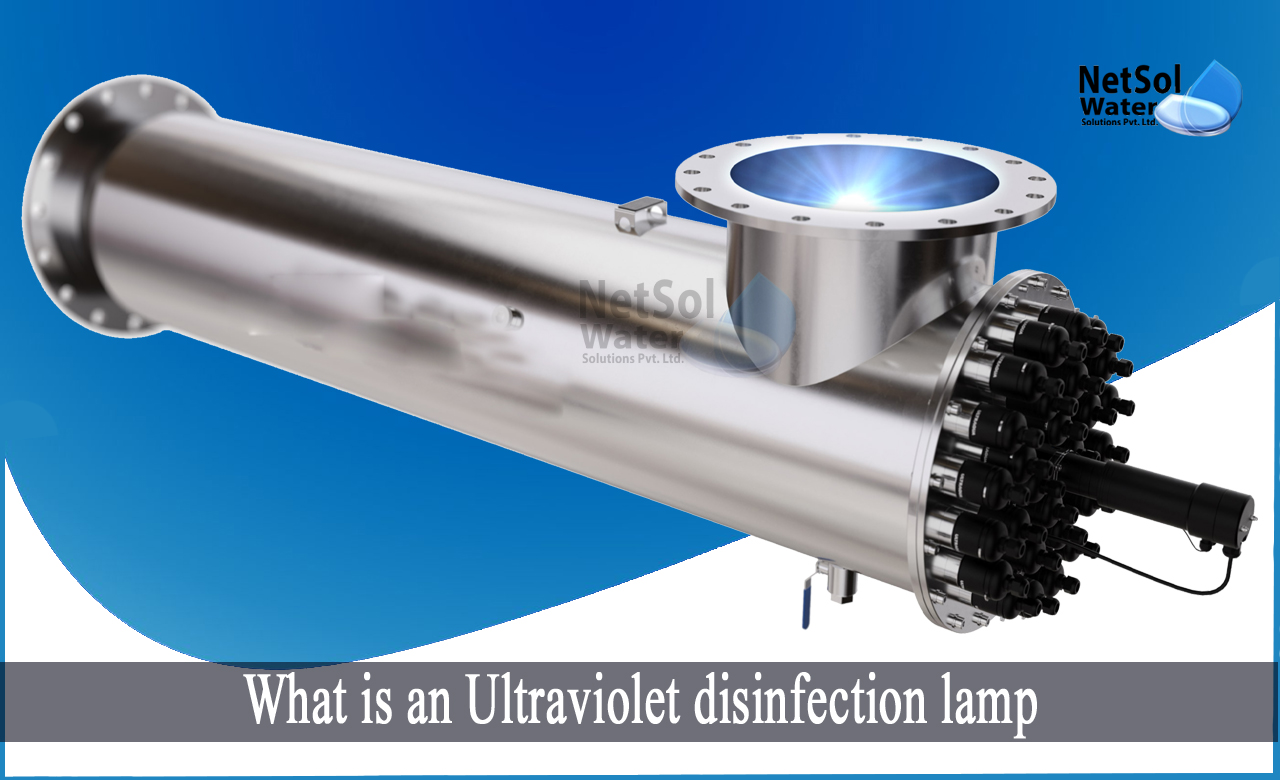

Many treatment systems pay careful thought to one single fundamental element, which could be described as the systems "heart and soul." The Ultraviolet (UV) lamps are this component in the case of a UV disinfection system.

In this article, we will discuss about some common types of UV disinfection lamps for disinfection of water.

What is an Ultraviolet disinfection lamp?

The UV light needed to destroy the pathogenic elements in the treatment of water, is produced by a series of lamps. UV lamps often have some kind of metallic filament that generates an electrical arc, which excites mercury vapour. When the vapour is excited, it heats up, creates more pressure inside the tube, and emits UV radiation.

The UVC subtype is preferred for disinfection, however, because of its short wavelength, it cannot penetrate through ordinary glass, hence, the lamp's main body is composed of a quartz sleeve.

There are some terms associated with UV lamps, which are described below.

1: UV lamps output

The UV lamp's output measures the UV radiation's strength. The pressure inside the lamp, which is created by raising the temperature, affects output.

1a: High power: At higher powers, germicidal efficacy is more strongly influenced by higher radiation emission.

1b: Low power: Radiation with a lower energy output has a lower pathogen-inactivating efficiency.

2: Pressure

The internal gas pressure of the lamp is referred to as its pressure. The gas's radiation output is dependent on its pressure level. Only low or medium pressure will produce UVC light in mercury-vapour lamps. Visible light will also be produced at higher pressures.

2a: Low pressure: At this pressure, a single band of radiation with a wavelength of 254 nm is produced. This wavelength has been found to be the most germicidal. The output of this wavelength is stronger at low pressure.

2b: Medium pressure:A wide range of wavelengths above and below 254 nm is produced at this pressure. The 254 nm wavelength's intensity is not as strong, but the increased pressure allows for coverage of other wavelengths, to cover anything that is not impacted by the 254 nm wavelength.

3: Two Standard UV Lamps

To handle the flow rates of the water to be treated, facilities often use two specific bulb types in industrial, commercial, and municipal water treatment systems.

4: Lamps with Low Pressure and High Output

These lamps are both electrically and germicidally efficient. Low pressure and high output, both promise reduced power consumption, and increased germicidal effectiveness. These lamps work well for moderately high flows, in settings where power efficiency and a little more room are priorities. Their features include,

· Spectrum in one colour

· Centred input power

· A respectable energy efficiency

· A moderate operating temperature

· A decent lamp life

· Small footprint (in terms of number of lamps)

5: Lamps with Medium Pressure and High Output

Because, they cannot be used at low output intensities, these are more commonly referred to as medium pressure (MP) lights. In facilities with limited space requirements, and the ability to tolerate increased power consumption, these are the most potent UV lamps. These are most effective at higher flow rates. Their features include,

· Multicolour spectrum

· A strong input power range

· Decreased efficiency

· A wide range of operating temperature

· Reduced lamp life

· Limited footprint (for number of lamps)

6: Lamps with Low Output and Low Pressure

Because, they are less efficient than LPHO or MP systems at high flow rates, and would need a lot more UV lamps, LPLO disinfection systems are less popular. They would, however, be the most economical for much smaller applications, and have the highest energy efficiency of the three systems.

Conclusion

Depending on the application, using a specific bulb in a disinfection system may be more or less advantageous. LPHO is usually a good choice, since it offers a little bit of the best of both worlds, outperforming MP in terms of energy efficiency and bulb life, while outperforming LPLO in terms of effectiveness at killing pathogens with fewer lamps.

How can we assist?

For the client's project, the system designer at Netsol Water will be able to examine all input and output requirements, and choose the most practical and effective option.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.