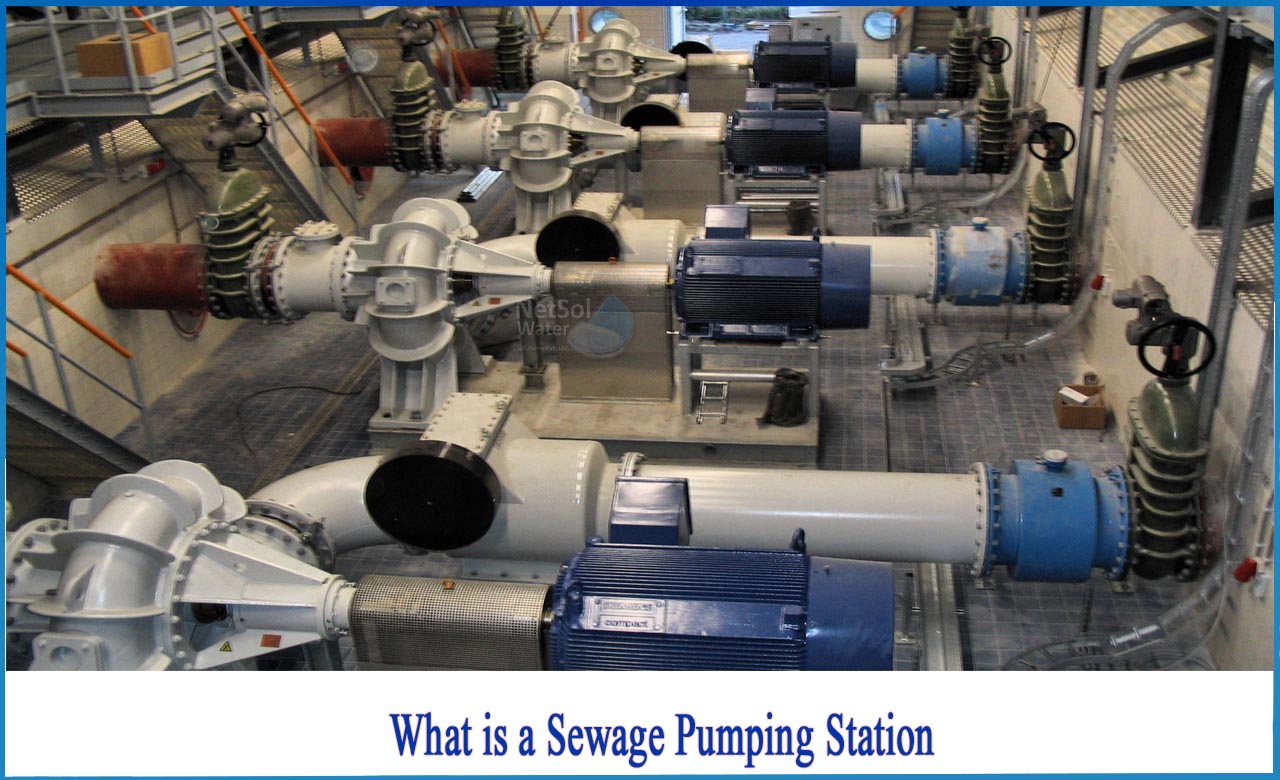

What is a Sewage pumping station?

Pumping stations in wastewater treatment are designed to collect and convey wastewater to a higher elevation. These are also called as Lift stations. It is generally intended to manage wastewater that is supplied from subterranean gravity pipes and stored in a pit or wet well. The wet well is outfitted with electrical equipment to detect the presence of wastewater. When the wastewater level reaches a specified level, the pumping station activates: a pump begins to push the wastewater upwards through a pressurized pipe system, which dumps the effluent into a gravity manhole. The cycle begins again until the effluent reaches its final destination, which is generally a wastewater treatment plant. When there is a large flow of water, for example, during peak flow periods and wet weather, multiple pumps will start in simultaneously. Pumping stations are often classified as pressured pumping stations (small), network pumping stations (middle), or major pumping stations (large).

When is a pump station required?

1: When the expense of constructing groundworks to allow sewage to flow by gravity exceeds the cost of constructing a sewage pumping station.

2: When a sewage line crosses a ridge.

3: If the basement floors are too low to enable gravity movement of sewage.

4: Where there is no gravity system.

What are the benefits of a Sewage Pump Station?

1: A pump station is useful when establishing a sewage system and has the ability to reduce construction costs.

2: Remote monitoring devices are installed at pump stations to keep operators informed.

3: Sewage is pumped mechanically without human intervention, reducing the danger of health concerns.

4: Pumps of various sizes are available for both household and commercial uses.

5: The intake of the pumps is frequently large to avoid blockage.

6: Alarms are installed in sewage pumping systems to warn you to system faults. Because you are warned promptly, the risk of sewage overflow is reduced.

What are the steps to take prior to the installation of the Pumping Station?

1:Look for surface water

To measure the workload of the pumps, you need to confirm or rule out if precipitation, surface water, or roof water is entering the system, either indirectly or directly.You must determine if the public sewer system is a combined system.

2: Make an informed decision regarding the type of pump you want

There are pumps that can chop up plastic bags, plastic cups, and tin cups. You should meet with the owners and explain the dangers of plastics being broken up into little bits in order for them to flow more freely into the public sewer.

3: To avoid issues, empower yourself with knowledge

Fat, grease, and oil are the most troublesome substances at pumping stations. This should be disclosed to our clients since it adheres to the float switches to the point where they no longer operate properly. They do not turn off the pump or prevent it from running the pumping station dry.

Netsol Water is a one-stop utility partner for industrial and commercial clients, assisting them in increasing resource productivity and bottom lines while protecting the environment.Contact our team for more information on sewage pumping stations or to schedule a survey. We will apply our decades of knowledge to give you with simple answers to your water and sewage treatment issues.

Please contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com for further information or to make a purchase.