What is a Screw Pump?

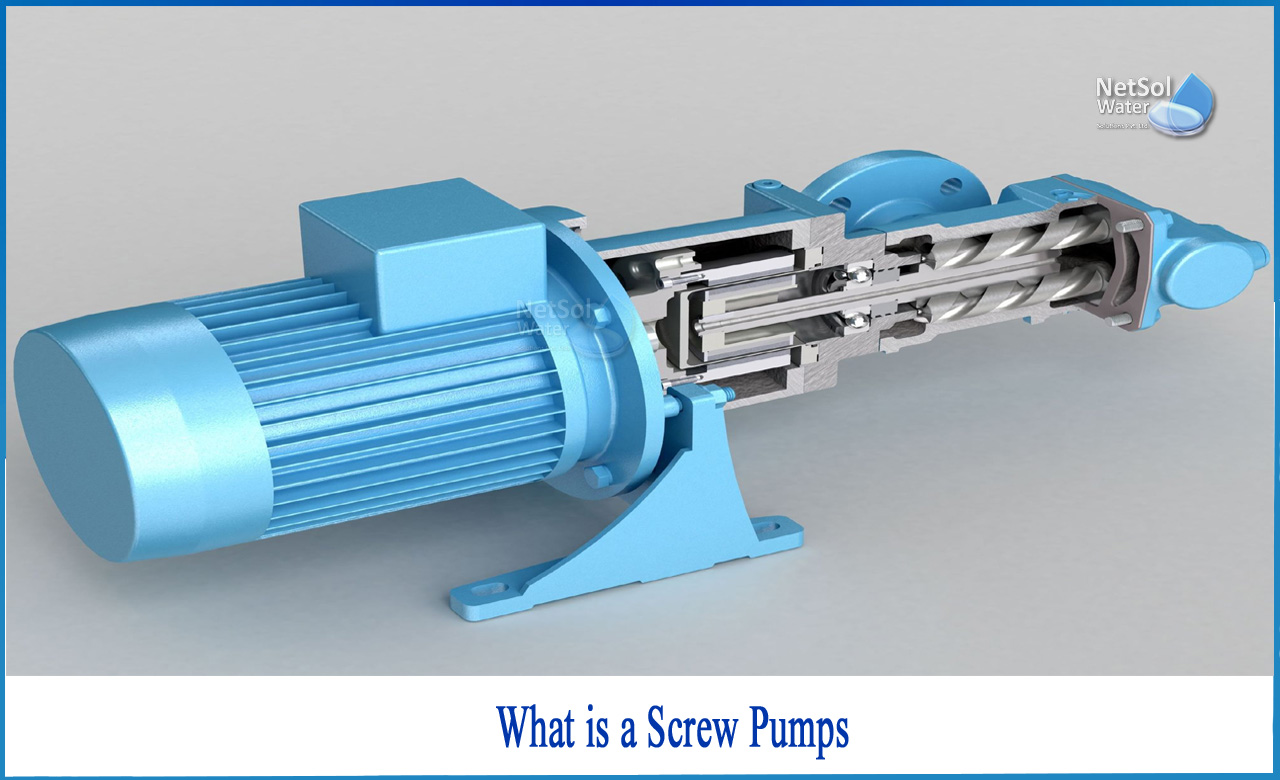

This is a positive displacement pump that may be constructed using many screws. These screws are linked together to pressurize and circulate liquids inside a system. The pump's screws take the fluids and push them out of another surface while increasing the pressure.

This pump's structure is both consistent and straightforward. It contains three screw spindles, one of which is a driver and the other two are driven. The fluid pumping motion is accomplished by these screws having a good clearance between them. The screw is supplied with liquid from the engine as a whole.These pumps feature a casing with an inlet and an outlet, with the inlet always being picked at the bottom of the pump and the outlet being selected at the top. All of these may be seen in the construction process. At the output end, there is a relief valve.

Working principle of screw pumps

When the screw pump is pushing a thick fluid, the screws can be tightly linked without authorization because the faces are greased as the liquid is pumped. When the fluid is pumping, these portions are unable to communicate with one another, resulting in rapid wear on the elements. A three-screw pump should not be used for multi-phase or water service because of this. Only shaft seals are required over the rotor drive in triple screw pumps. Bearings are included on additional rotors, which are protected within the pumping hall. Rotors extend throughout the pump container into a gear container where the timing gears reside in a 2-screw pump otherwise a 4-screw pump.

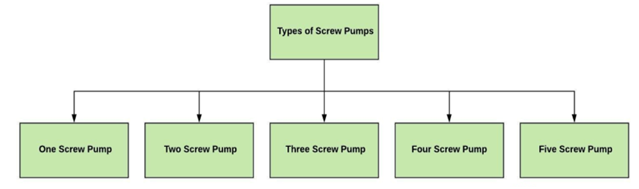

Types of Screw Pumps

Screw pumps are available in a variety of styles and designs in the market.

Let’s explore th?em one by one!

1: Pump with a Single Screw

PC pumps, also known as progressive cavity pumps and worm pumps, are two types of these pumps. In general, these pumps are not regarded to be part of the screw-pump family. Because the rotor in these pumps is more akin to a twisted round shaft than a typical screw. A progressive cavity pump consists of one shaft that is twisted into the shape of a screw and is enclosed within a rubber-lined pumping hall.

2: Pump with two screws

These pumps are also known as double screw pumps, and they are the most common kind utilized in high-power applications such as the transfer of heavy oil tubes. The motor drives the screws in the pumps, and timing gears are usually provided to turn the next screw.

3: Pump with three screws

These pumps, also known as triple screw pumps, are often utilized in minor applications such as lubricating systems. The remaining two screws in the pump are rotated without the use of timing gears since the screws in the pump are dictated by the motor.

4: Pump with four screws

These pumps are essentially two screw pumps, but with two screws in opposing directions for each rotor. These pumps absorb the liquid in the suction port, split it evenly, and send it to both ends of the pump.

With the aid of the pump, the two liquids flow towards the centre and reconnect before exiting the release port. This pump, like the double screw pump, has a timing system that allows the second rotor to run. Multi-phase applications and oil transport pipes typically employ these pumps.

5: Pump with Five Screws

These pumps are similar to triple screw pumps, however they have five instead of three screws. This pump, like the three-screw pump, has a single diving rotor that drives all of the other screws. This sort of pump is commonly utilized in a variety of applications, such as tube oil or hydraulics.

Advantages and Drawbacks

The following are some of the benefits and drawbacks of screw pumps.

1: These pumps have the highest flow rate of any PD pumps.As a result, these pumps are the greatest option for persons who work with non-movable liquids that need to be moved fast, such as oil, gas, and other thick liquids.

2: These pumps are suitable for both 2-phase fluid and gas combinations. However, these are not suited for moving dirt-free liquids at consistent rates, with the exception of pumps. In comparison to easier pumps, the complexity of these pumps typically comes with increased protection and tiny gear.

Applications of Screw Pumps

The following are some of the uses for screw pumps:

1: These pumps are used in a wide range of sectors, including oil, manufacturing, gas, and mining.

2: The majority of pump applications are high viscosity fluids, such as asphalt, or multi-stage liquids, in which fluid and steam are combined together inside the liquid stream.

3: Multi-phase Pumping, Lubrication, Hydraulic Systems, and Weighty Oil Pipeline are some of the applications for these pumps.

Conclusion

Screw pumps are used commonly. Sometimes, these pumps are chosen based on single suction, while other times, they are chosen based on double suction. The liquid enters from one side and leaves from the opposite side of the two screw pumps, which have single suction. Similarly, four screw pumps have a double suction configuration, with a suction stream that splits at both ends and runs through a central outlet.

If you are curious to know more about the screw pumps, then you can clear your curiosity by connecting to Netsol Water Solutions.

You can have a healthy discussion with our expert!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.