What are the various Piping requirements in WWTP?

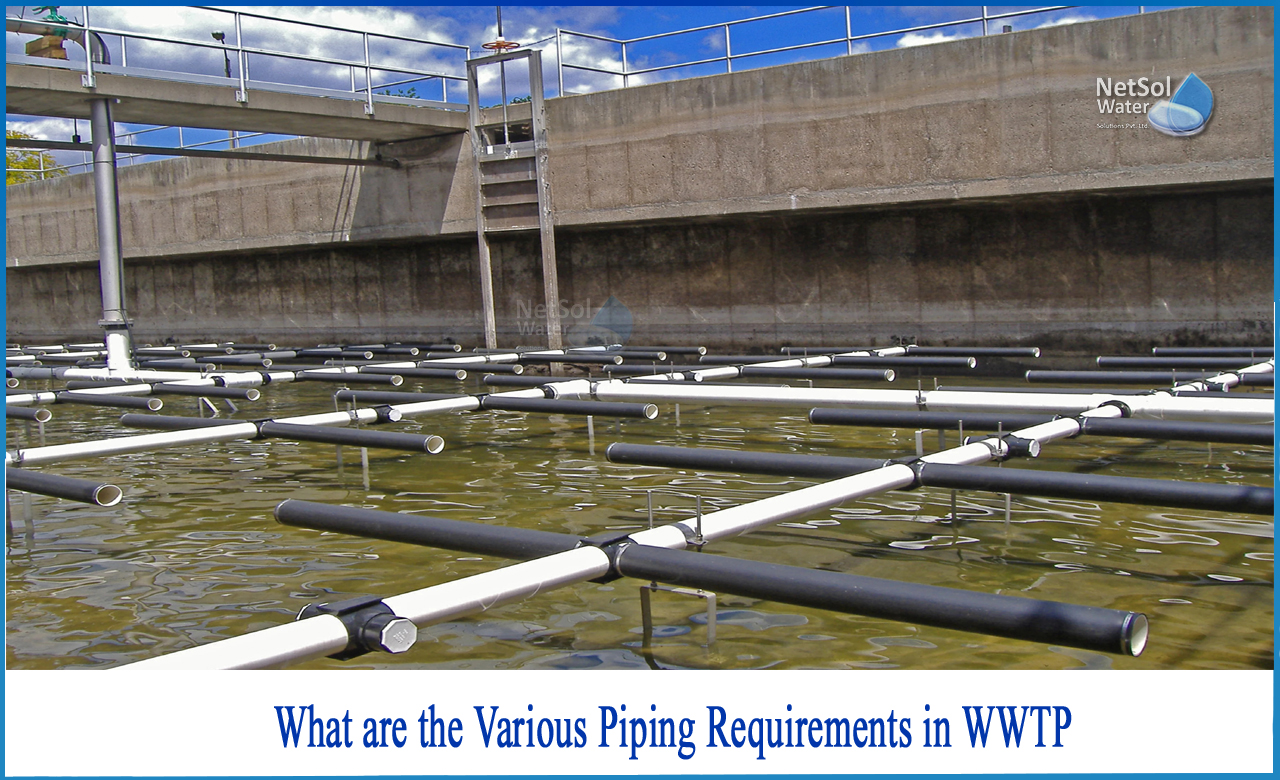

Modern water and wastewater treatment systems, water pumping units, desalination units, cooling water systems, and other systems all rely on piping. The veins of contemporary plants are similar to piping systems. Water, wastewater, chemicals, and mixes are all transported by pipelines from one point to another.

Understanding piping fundamentals, materials, generic and specific considerations, fabrication and installation, examinations, and testing and inspection requirements, as well as local and international regulations, all are required for the design, construction, operation, and maintenance of various piping systems.

Pressure drop/Head Loss in Piping Systems

Because of friction inside the pipe and fittings, as well as elevation variations, pressure drop or head loss happens in all piping systems. Turbulence generated by sudden changes in direction causes pressure decrease, which is normally included in the overall frictional pressure loss.

As a preliminary approximation, the frictional pressure loss for 10 m of water piping with a velocity of 1 m/s would be around 0.1 m of head (or say, 1 m frictional head for 100 m of pipe). This is a very preliminary estimate for a pipe with a diameter of 4 to 8 inches (DN100-200mm).

Note:Pressure drop is likely to be greater in small diameter pipes and it may decrease in larger diameter pipes.

Water and Wastewater Tanks, drums, and vessels including Piping Systems

Tanks, filters, pressure vessels, drums, and other fixed equipment’s have long been employed in water and wastewater treatment plants and other water-related facilities. Low-pressure or atmospheric tanks and drums typically have thin shells, and the stresses transmitted from piping to tank and drum shell nozzles can be problematic.

The following are some of the loads and effects to consider while connecting pipework to tank and drum nozzles:

• Rotation of the nozzle and radial movements of the shell while filling and emptying a tank or drum.

• The combined weight of the piping, valves, and contents.

• Piping movements.

These load combinations should create modest and manageable stresses in the pipes.The equipment nozzle and its connection should also be tested for moment loads and the consequent local strains.

Most systems benefit from having the first horizontal bend of the line as close to the equipment nozzle as practicable. After this first bend, torsion in the leg of horizontal pipework allows the shell nozzle to rotate.

Bare minimum of flange connectors

In pipes, the rule of "no extra flange" is well-known. This guideline simply states that no more flanges should be used unless they are absolutely necessary, such as for valves, in-lines, pump and equipment nozzles, necessary piping spools, and so on.

Any flange pair could be a source of leakage. Any disassembly of flange connectors necessitates the replacement of gaskets and labour. It's also worth noting that flange connectors are expensive. If flanges, bolts, several gaskets, many labour hours, and other charges are employed in an inappropriate area, the total cost will be exorbitant.

Drains and vents

Pressure testing, starting, cleaning (such as chemical cleaning), decommissioning, and other operational scenarios for pipe systems of water-related facilities generally require provisions for low-point drains and high-point vents. When testing, venting, and draining are needed on a regular basis, valved drain and vent connections are also supplied.

If possible, these drains and vents should be positioned on the equipment, but if there are no valves or blocks in between drain or vent connections and the equipment, they can be located in associated pipework. Draining the equipment and the related piping to the appropriate drainage system should be arranged using piping from drain connectors.

Criticality of piping in Water and Wastewater Treatment Systems

It's critical to recognise the many characteristics of pipes in water and wastewater treatment plants, as well as other water-related facilities, and thus factor these elements and parameters into the piping design, engineering, installation, and operation processes.

If you want to know more aboutpiping requirements in water and wastewater treatment plants, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Call us on +91 9650608473