What are the typical Design Parameters for Step feed Technology?

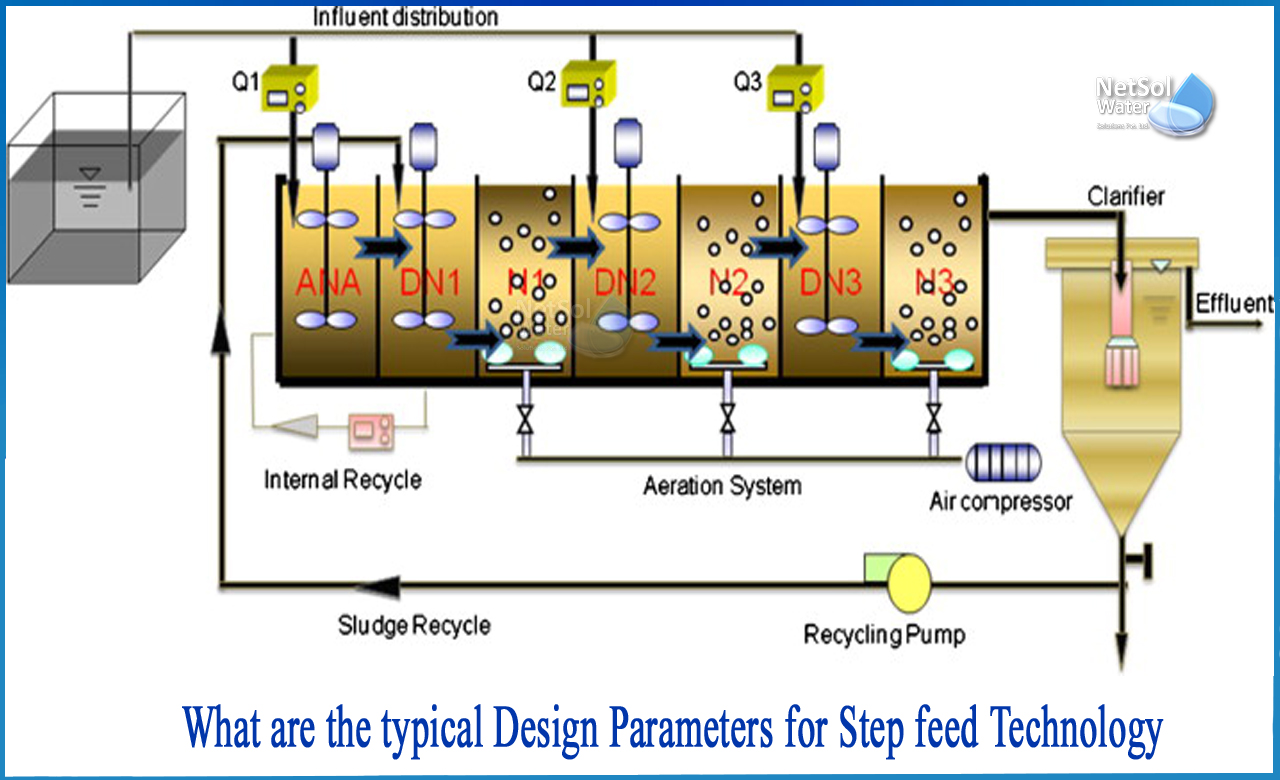

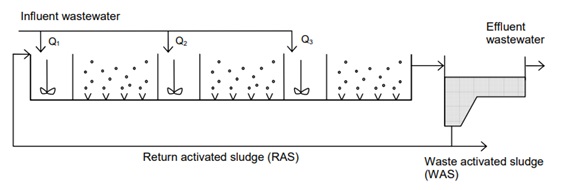

The step-feed technology feeds influent wastewater into the biological reactor in stages providing readily biodegradable organic material to the denitrifying bacteria in several compartments. If nutrient removal is desired, the basins are separated into numerous zones with differing biochemical conditions, comparable to the standard activated sludge BNR method.

At the basin's head, all return microorganisms (sludge) are introduced. When compared to a plug-flow system with the same basin capacity, a larger solids retention period is achieved by dividing the flow to various influent feed points and routing recovered sludge to the beginning of the process.

Characteristics of Step-Feed process for Nutrient removal

Anoxic zones for denitrification and oxic zones for oxidation of organic material, nitrification, and phosphorus absorption are common characteristics.Denitrification occurs when nitrified mixed liquor is reintroduced from the oxic zone to the anoxic zone.

Figure shows a three-stage pre-denitrification system with step-feed pre-denitrification

Stepfeeding not only saves energy by lowering the need for pumping, but it also produces MLSS concentration gradient in the tank. At the head end of the reactor, the return sludge will only be slightly diluted with the entering wastewater, and the MLSS will be greater in the early compartments. This means that in the step-feed process, the average MLSS in the tank may be larger – compared to a traditional plug-flow system – without raising the solids loading to the secondary clarifier, and therefore SRT can be enhanced.

Applicability of Step-feed Multiple Biological Nutrient removal process

1: Modifications to existing facilities are possible.

2: Installing partitions in the reaction tank, producing anoxic and aerobic zones, and adding a distribution system for the step-feed of the primary effluent may all be done without jeopardizing existing treatment capacity.

3: All of the recirculated sludge must be returned to the front end of the tank and not mixed with the influent sewage for it to be effective.

4: It tackles the frequent issue of filaments at the front end of the tank caused by high F/M and filaments at the rear end of the tank caused by low F/M.

Advantages and Disadvantagesof Step-feed Multiple Biological Nutrient removal process

The follow?ing are the benefits and drawbacks of this method:

a. Aspects that are favorable

i. Waste load equalization is improved;

ii. Operational adaptability;

iii. A more consistent oxygen demand throughout the aeration tank, with a reduced peak demand;

iv. Provides operational control over the age of the sludge and the length of time it spends in the hydraulic reservoir;

v. Prevents catastrophic process failure owing to hydraulic overloading or sludge thickening;

vi. The sludge is reused numerous times in the tank, increasing the BOD treatment capacity;

vii. This design minimizes the size of the aeration tank and the time it takes to aerate it while maintaining BOD removal effectiveness. The reduced aeration time lowers capital costs.

b. Aspects that are unfavorable

Mechanical and control equipment must be properly maintained and operated in order to achieve adequate flow distribution and liquid recirculation.

Design Parameters that are typically used in Step-feed Multiple Biological Nutrient removal process

The process's main design requirements are listed below:

Important considerations related to design of Step-feed Multiple Biological Nutrient removal process

a. DO (0.2 mg/L)_ anoxic tank and DO (2.0 mg/L) _oxic tank;

b. Denitrification Rate: 60-80%

c.It has a small footprint. The tank capacity is decreased to half of a traditional circulating operation due to the reduction in hydraulic retention time.

d. It is a low-energy device. Energy usage can be reduced to roughly 70% of the conventional recirculation procedure depending on the necessity for nitrified liquid recirculation.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated problems by strategically integrating modern treatment technology with practical solutions. We are the leading name for manufacturers of water and wastewater treatment plants including Stabilization Ponds, and is known to be NO. 1 at solving complicated processes like nutrient removal.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.