What are the types of Trickling filter?

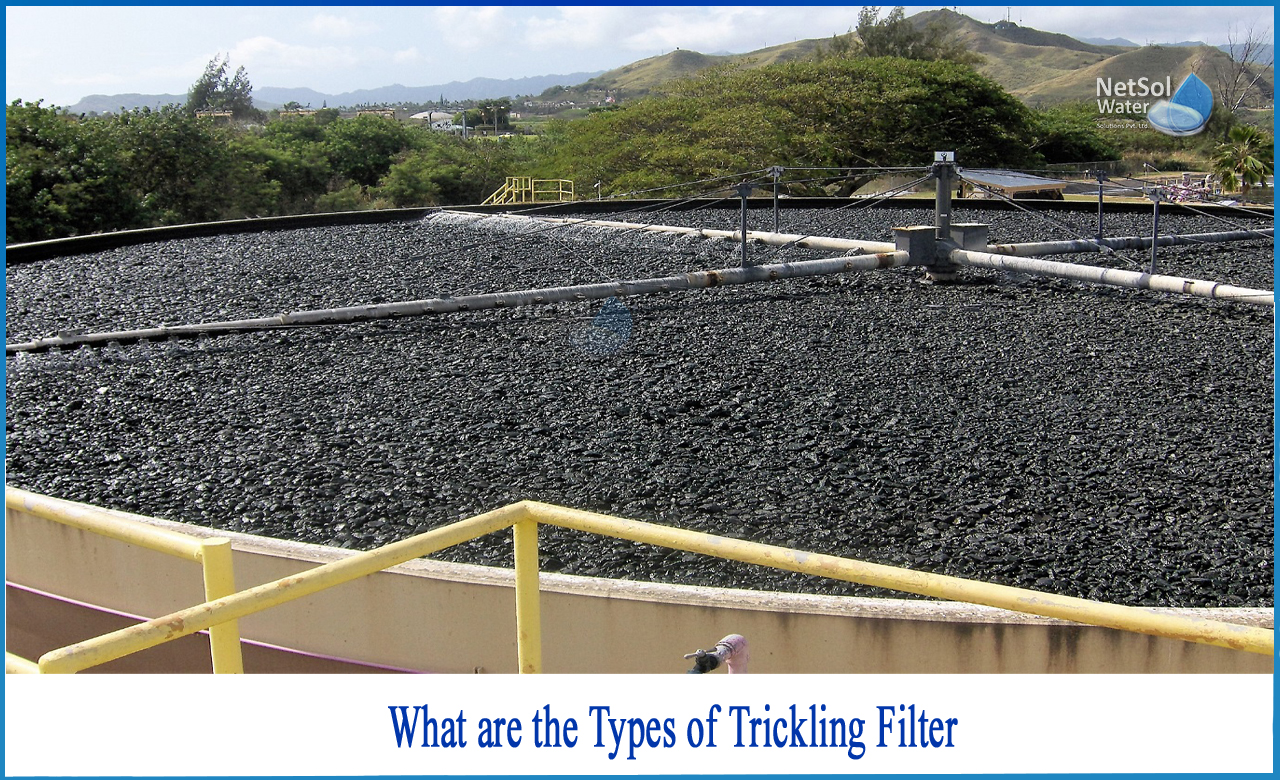

A Trickling Filter is made out of a permanent bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media, over which sewage or other wastewater runs downhill, causing a layer of microbial slime (biofilm) to form and cover the bed of media.

Splashing, diffusion, and either forced air flowing through the bed or spontaneous convection of air if the filter media is porous sustain aerobic conditions. The treatment of sewage or other wastes with these filters is one of the oldest and most well-known treatment methods.

Types of Trickling Filters

1. Trickling filter at a low rate or Low-Rate Trickling Filters (LRTF)

The standard rate or low-rate trickling filters (LRTF) are very basic treatment devices that often yield constant effluent quality even when influent intensity varies. They are not usually supplied with effluent recirculation. Depending on the dosing system, wastewater is sprayed intermittently with rest intervals of no more than five minutes at the designated waste flow rate.

The LRTF, comprising primary and secondary sedimentation units, removes 80 to 85 percent of the applied BOD with adequate loadings. While certain solids are unloaded or sloughed at all times, the primary emptying normally occurs many times a year for relatively brief periods of time.

2. High-Rate Trickling Filters (HRTF)

The High-Rate Trickling Filters (HRTF) feature the same construction details as the Low-Rate Trickling Filters (LRF), but they include effluent recirculation.

A portion of the treated settling effluent is pumped to the PST or the filter. The recirculation of wastewater is a critical component of the HRTF. As a result, the entering wastewater is diluted and the TSS content is lowered. High-rate filters often have greater hydraulic and organic loadings than low-rate filters. The increased BOD loading is achieved by adding a greater volume of waste per unit surface area of the filter. Incorporating recirculation is one way to improve the efficiency of a trickling filter. The hydraulic loading per unit area of filter media increases when recirculation is utilized.

As a result, larger flow velocities are more likely to occur, resulting in a more continuous and uniform sloughing of surplus growths. Under typical operation, high-rate trickling filters, including primary and secondary sedimentation, should remove 65 to 85 percent of the BOD from the wastewater.

3. Roughing Filter

Roughing filters are high-rate filters with plastic packing. Roughing filters are often used to treat wastewater prior to subsequent treatment. When compared to the activated sludge process, one of the advantages of roughingfilter is the low energy demand for BOD removal of high strength wastewaters since the energy required is solely for pumping the influent wastewater and recirculation flows.

4. Two-Stage Trickling Filters

A two-stage TF system with SST effluent recirculation is used. With high strength wastewater, a two-stage TF system with an intermediate settling tank (IST) to remove particles produced by the first filter is most commonly utilized. When nitrification is necessary, two-stage TF systems are also employed. Carbonaceous BOD is reduced in the first step by a filter and an intermediate clarifier, and nitrification occurs in the second stage.

What is the use of a Trickling Filter? What is its role in the treatment of industrial wastewater?

Industrial wastewater treatment may entail the use of specialized trickling filters with plastic media and high flow rates. Trickling filters have been used to cleanse wastewater from a range of industrial operations.

There are two kinds of industrial wastewater trickling filters:

1: Large concrete enclosures or tanks filled with plastic packing or other material.

2: Vertical towers containing plastic packaging or other media.

Because of the low cost of plastic tower packings, they are being used as trickling filter beds in tall towers, as tall as 20 meters.

Conclusion

As with other trickling filter applications, the treated wastewater effluent from industrial wastewater trickling filters is often handled in a clarifier to remove the sludge that sloughs off the microbial slime layer adhering to the trickling filter medium.

Some of the most recent trickling filter technology consists of aerated biofilters of plastic media in vessels that use blowers to inject air at the bottom of the vessels, with either downflow or upflow of the wastewater.

What can we offer?

Netsol Water is a large water and wastewater treatment company in India that manufactures WTP, WWTP, STP, ETP, Industrial & Commercial RO Plants, among other services. It has become our job to rescue the earth. The firm manufactures equipment’s and is dedicated to offering practical solutions that enable businesses to thrive.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.