Overview

Many municipalities have investigated utilizing desalination technologies to supply fresh water when conventional sources and treatment procedures are uneconomical or not ecologically responsible as populations grow and supplies of high-quality fresh drinking water become scarce.

What is desalination?

Any technique that removes excess salts and minerals from water is referred to as desalination. In most desalination procedures, feed water is treated, and two streams of water are produced:

- treated fresh water with low salt and mineral contents

- Concentrate or brine with greater concentrations of salt and minerals than feed water

Seawater or brackish water can be used as the feed water for desalination procedures. Brackish water has more salt than fresh water but less salt than salt water. It is most usually found in estuaries, which are the lower courses of rivers where they meet the sea, and aquifers, which are subterranean reservoirs of water.

Water Sources

Seaw?ater: Seawater is drawn into a desalination plant from either the water's surface or from beneath the sea floor.

Brackish Water: Brackish water is a frequent feedstock for desalination plants. It is often drawn from nearby estuaries or brackish inland water wells. Because it contains less salt and a lower percentage of suspended particulates than saltwater, brackish water requires less preparation, lowering overall outputcosts.

What are the technologies for thermal desalination?

Thermal distillation and membrane distillation are the two most common distillation procedures used for desalination across the world.

Thermal distillation methods are frequently employed in the Middle East, owing to the region's abundant petroleum reserves, which keep energy prices low. Multistage flash distillation (MSF), multi-effect distillation (MED), and vapor compression distillation are the three basic large-scale thermal procedures (VCD). Solar distillation is another thermal process that is mainly utilized for extremely tiny output rates.

Membrane distillation methods treat the feed water by forcing it through membranes using a pressure gradient. Electrodialysis (ED), electrodialysis reversal (EDR), and reverse osmosis are the three basic membrane processes (RO).

Thermal technologies

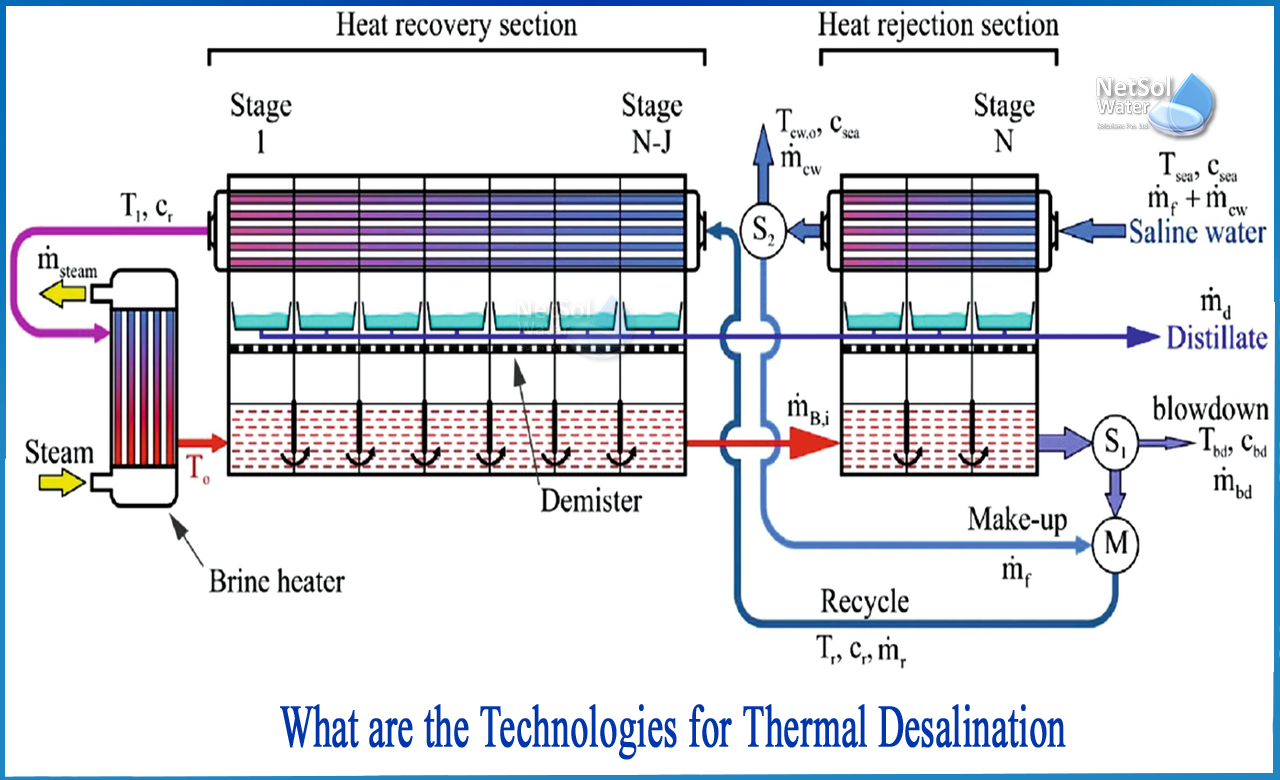

1: Multi-stage flash distillation

The procedure of multi-stage flash distillation involves passing the saline input water through many chambers. The water in these chambers is heated and compressed to a high temperature and pressure. As the water moves through the chambers, the pressure decreases, causing the water to boil quickly. The vapor, which is fresh water, is created by boiling in each chamber and then condensed and collected.

2: Distillation with several effects

Multi-effect distillation follows the same principles as multi-stage flash distillation, except that instead of numerous chambers in a single vessel, MED utilises succeeding containers. The water vapor produced as water boils is condensed and collected. The use of numerous containers improves the efficiency of the MED procedure.

3: Vapor compression distillation

Vapor compression distillation can be used alone or in conjunction with another thermal distillation technique. The heat generated by the compression of vapor is used by VCD to evaporate the supply water. VCD units are frequently used to generate fresh water for small- to medium-scale applications including as resorts, industry, and petroleum drilling sites.

4: Distillation using the sun

Solar desalination is often employed on a modest basis. Although the designs of solar distillation units differ widely, the fundamental principles remain the same. The sun generates the energy required to evaporate the salty water. The evaporation process produces water vapor, which condenses on the transparent glass or plastic covering and collects as fresh water in the condensate trough. The covering transmits solar energy while also allowing water vapor to condense on its inside surface. The brine solution is formed by the salt and un-evaporated water is left in the still basin and must be removed properly. This approach is commonly employed in desert locations where clean pure water is scarce. Depending on their design and location, solar distillation units generate varying volumes of fresh water.

Conclusion

As high-quality freshwater supplies dwindle, more communities may choose brackish and salt water desalination to create drinking water.Based on site-specific limits and requirements, all desalination processes offer advantages and drawbacks. Small-scale brackish water desalination using solar stills is a viable solution in rural areas where good-quality drinking and cooking water is scarce.

Netsol Water is one of India's leading manufacturers of various types of water treatment facilities.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.