What are the Essential Tools and Methods for STP Plants?

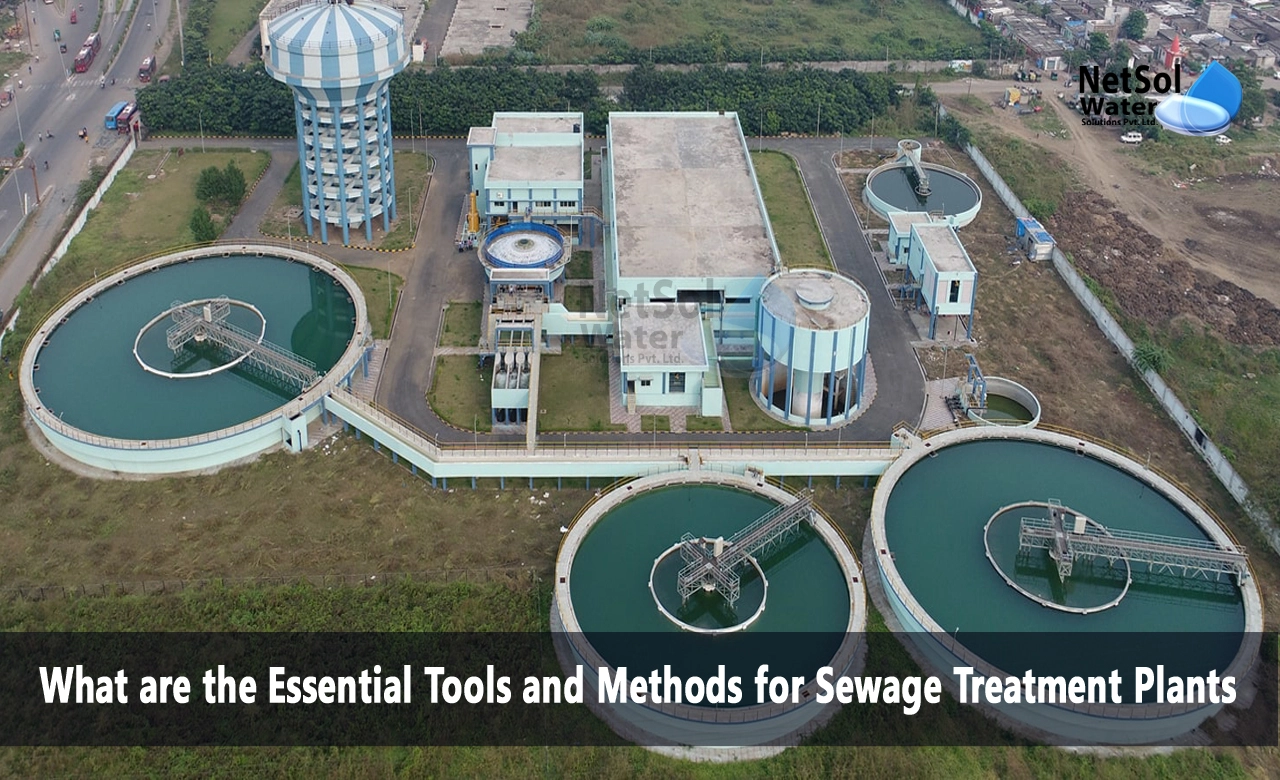

Sewage treatment is the process of removing contaminants from wastewater before it is discharged back into the environment. It is a crucial public health measure that prevents the spread of disease and protects water resources from pollution. We will explore the main tools and methods utilized in sewage treatment plants to clean wastewater effectively.

Essential Tools and Methods for Sewage Treatment Plants:

1- Preliminary Treatment

The first stage of sewage treatment involves removing large objects and grit from the incoming wastewater flow. This is achieved using bar screens, which are metal grids that catch solid objects like rags, plastics and debris. The wastewater then passes through grit chambers, where sand, gravel and other heavy inorganic material settle out. These preliminary processes protect downstream equipment from damage and clogging. Comminutes may also be used to chop up larger debris into smaller pieces.

2- Primary Treatment

Next is primary treatment, which removes suspended organic solids from the wastewater. This is accomplished through sedimentation tanks, also called primary clarifiers. Here, solids sink to the bottom and a layer of grease and scum floats to the top. Scrapers, skimmers and sludge collection equipment then remove the separated sludge and scum. The effluent from primary clarification may also pass through flocculation tanks, where chemicals (flocculants) are added to help coagulate and precipitate more suspended solids for removal.

3- Secondary Treatment

After much of the suspended solids are removed, secondary treatment steps work to substantially degrade dissolved organic matter. The predominant method is through aerobic biological treatment in activated sludge tanks. Air is pumped into the tanks to provide oxygen to support microbial growth. The microbes metabolize organic substances, thereby removing them from the wastewater. Clarifiers then separate out the microbes (activated sludge) to be recycled back to the aeration tanks. Other techniques like trickling filters and rotating biological contactors may also be used for secondary treatment.

4- Tertiary Treatment

Tertiary or advanced treatment provides further purification by removing specific residual contaminants. Common tertiary treatment methods include:

i- Filtration using sand, anthracite or activated carbon filters to remove fine particles.

ii- Nutrient removal through biological or chemical methods to reduce excessive nitrogen and phosphorus levels.

iii- Disinfection using chlorine, ultraviolet radiation or ozone to kill disease-causing pathogens.

5- Sludge Treatment

The sludge extracted from primary and secondary clarifiers requires processing before disposal. Treatment steps include thickening, stabilization, conditioning and dewatering. Thickening increases sludge solids concentration, while stabilization reduces odors and pathogens either anaerobically through digestion or aerobically through aeration lagoons. Conditioning chemically prepares the sludge for mechanical dewatering, which further reduces sludge volume. The treated sludge has many beneficial reuse options like land application, incineration or land filling.

Instrumentation and Controls

Modern sewage treatment installations rely heavily on instrumentation, automation and control systems. Flow meters, level sensors and analyzers continuously monitor parameters like flow rates, tank levels, pH, dissolved oxygen and suspended solids. Programmable logic controllers collect this data to regulate treatment processes via feedback control. Overall, instrumentation improves operational efficiency, process optimization and reliability.

Conclusion

Effective sewage treatment is vital for protecting public health and the environment. It involves multiple stages to remove physical, chemical and biological contaminants from wastewater. Key tools and techniques include screening, clarification tanks, activated sludge systems, tertiary treatment methods, sludge processing equipment and instrumentation for process control. A combination of these technologies enables sewage plants to produce treated effluent suitable for discharge or reuse.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com