What is a flow metre?

A flow metre is a device that measures the volumetric flow rate of liquids or gases. Flow metres come in a variety of shapes and sizes, including ultrasonic flow metres, electromagnetic flow metres, and others.

The following variables must be considered when purchasing a flow metre:

1) Type of flow measurement: Measurement of volumetric or mass flow

2) Liquid, gas, or slurry as a medium

3) Media conditions: media pressure and temperature, as well as whether media conditions are expected to stay the same or change.

4) Flow range: The media's needed flow range (min and max readings required)

5) Accuracy: The readings must be accurate.

6) Environmental considerations: Hygienic construction or tamper-proof readings are necessary in some applications.

How does flow meters help?

Municipalities may use flow metres to make a difference at every stage of the water production process, from collecting and purifying water to providing it to customers.

>Acquire: The first stage in successful water production and distribution is to acquire water. It entails controlling ground or surface water intake for efficient pump performance and downstream treatment, which necessitates the use of accurate flow metres. Electromagnetic, clamp-on ultrasonic, open channel, turbine, and differential pressure are the most often employed flow technologies.

>Clarify and filter: During the clarifying and filtration stages, it's critical to keep an eye on the flow to regulate the distribution of coagulants and polymers. Effective filtration backwash cycles are also ensured by proper monitoring. Electromagnetic, clamp-on ultrasonic, turbine, and differential pressure are some of the most advanced flow metre technologies.

>Treat and disinfect: Treating and disinfecting water include adding the proper amount of disinfectant, pH correction, corrosion inhibitors, and fluoride. These additives are necessary for disinfecting water in order to comply with strict safety regulations.

>Distribute: Water distribution is more complicated than simply delivering it to homes, buildings, and other structures. To help find leaks by closely monitoring flow, distribution loads must be balanced. Electromagnetic flow metres, as well as inline and clamp-on ultrasonic flow metres, are good choices for this process's highly accurate measurement.

>Deliver: Measure final delivery to houses, commercial buildings, industrial locations, and other facilities, or transfer service to another water authority, is the final stage in providing residents with safe drinking water. Electromagnetic, inline and clamp-on ultrasonic, and positive displacement flow metres are among the best flow metre technologies for this crucial final phase, ensuring delivery rates are collected effectively and successfully.

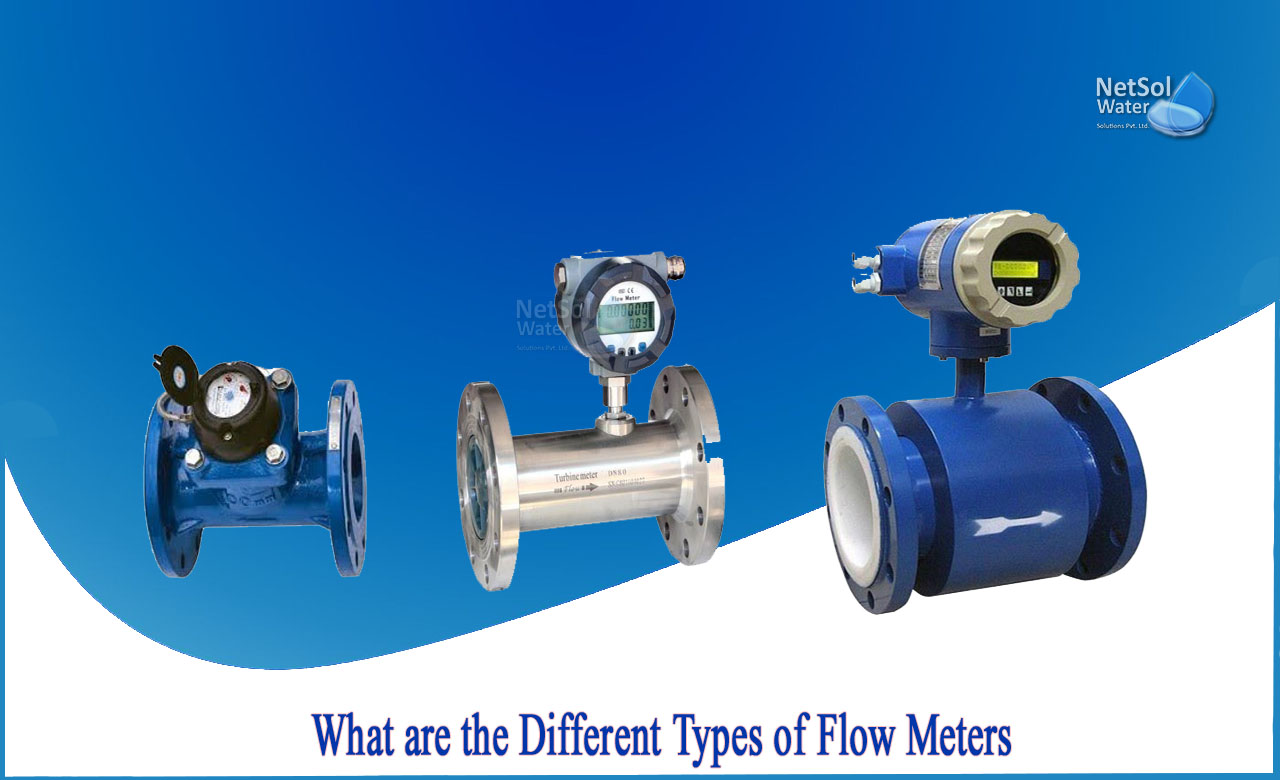

What are the different types of flow metres?

There are many types of flow meters. In this blog we know about different types of flow meter

>Ultrasonic flow metre: An ultrasonic flow metre is a flow metre that uses ultrasound to detect the velocity of a fluid. The device's clamp-on sensors create and receive ultrasonic waves in a non-intrusive manner. For homogeneous fluids with few suspended particulates and gas bubbles, an ultrasonic flow metre is ideal.

>Electromagnetic flow metre: Electromagnetic flow metre is used to measure the flow rate of liquids or slurries precisely. Electromagnetic flow metres does not have any obstructions. Because there are no moving parts, it requires no maintenance. It is extensively used to determine the flow rate of sewage. It can be used in:

· Syrup of sugar

· Slurry of Coal

· Water that is too hard to drink

· Beverages

· Acids and alkalis

· A chemical remedy

>Oval gear flow metre: An oval gear flow metre has oval gear rotors with great precision. The rotors spin within a container. The volumetric flow rate is determined by the frequency of rotation. A digital and mechanical display are included with oval gear flow metre. It is made of high-quality materials and is designed to house oval gears. The petrochemical and chemical industries both employ oval gear flow metres.

>V-cone flow metre: A V-cone flow metre is a differential pressure flow metre that is used in harsh environments to measure liquid, steam, or gas. V-cone flow metres from can be easily adjusted to meet the needs of the industry. V-cone flow metres are utilised in the most demanding applications because of its great mix of performance, low maintenance, and longevity. They can be employed in a variety of situations, including:

· Plastic industry

· Pharmaceutical industry

· Textile industry

· Power and water & wastewater applications

· Oil/gas production

· Chemical production

· Food & beverage industry

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.