What is sludge?

Sludge is a semi-solid slurry created by a variety of industrial processes, including water treatment, wastewater treatment, and on-site sanitation. It can be made from a settled suspension acquired from standard drinking water treatment, sewage sludge received from wastewater treatment operations, or faecal sludge obtained from pit latrines and septic tanks, for example.

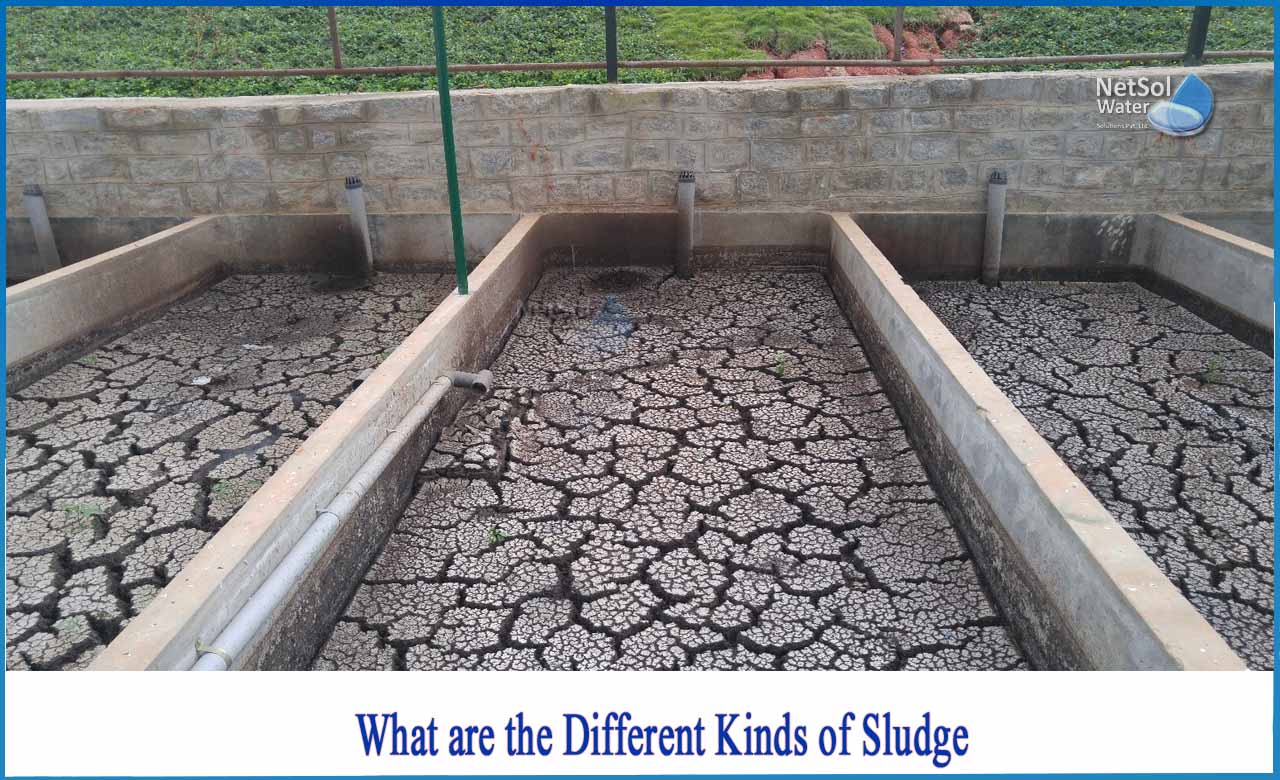

What are the different kinds of Sludge

After any industrial operation, there is material left over that has no other function than to be discarded as trash or used for other purposes. It is primarily found in sewage treatment plants and is produced as a by-product of treatment.

Various Types of Sludge

1: Raw Sludge: Sludge from raw sewage is often seen as an issue that must be addressed. It has a foul odor, harbors infections, and is mostly made up of water, which increases handling costs. The organic material in raw sludge, on the other hand, might be seen as a clean energy source with the ability to produce methane. Furthermore, because sewage sludge is high in organic matter, nitrogen, and phosphorus, it can be used as fertilizer once the aforementioned difficulties are rectified. Thermal hydrolysis followed by anaerobic digestion (AD) reduces odor, kills microorganisms, and increases dewater ability in the anaerobic digester, all while increasing methane production.

2: Return Activated Sludge: Contaminants are decomposed in the aeration tank with the help of biomass. In the final clarification, the biomass/activated sludge is separated from the clean effluent, the clear water is discharged into the receiving body of water, and the settled sludge is returned to the aeration tank such as return activated sludge. It's made available for biological eradication once more. The surplus sludge from the biological process is transferred to a sludge treatment facility.

3: Sludge Surplus: Unused biomass must be removed from the biological treatment system as extra sludge in order to maintain a constant sludge age. Due to metabolisms, the surplus sludge comprises non-hydrolysable particle components and biomass. The surplus sludge has a lot of moisture in it and is difficult to treat. Many scientists have worked on various projects to treat the extra sludge. These WWTP byproducts are dewatered, dried, and then burned into ashes. Some are utilized as compost fertilizer on farmland. Our civilization is burdened by the lack of ash dumps and the high expense of treating surplus sludge.

4: Activated Sludge: In the biological treatment process, dissolved organic matter and nutrients are eliminated from the wastewater. It is accomplished by the interaction of various bacteria and microbes, all of which require oxygen to survive, grow, and reproduce in order to devour organic waste. Activated sludge is the sludge that results from this procedure. The activated sludge is typically in the form of flakes, which comprise adsorbed, stored, organic, and mineral materials in addition to living and dead biomass. The sedimentation behaviour of the activated sludge flakes is critical for the biological treatment's performance. The flakes must be easily eliminated so that the biomass can be easily separated from the cleaned wastewater and a sufficient volume of activated sludge is fed back into the aerated section.

5: Primary and Secondary Sludge: Processes including sedimentation, chemical precipitation, and other primary processes produce primary sludge.Secondary sludge is waste biomass produced by biological treatment processes. It also covers any sludge that forms as a result of secondary industrial activities on primary sludge.

6: Drinking Water Sludge: Sludge from drinking water treatment plants or tanks are what this is. It is generally disposed of as non-hazardous trash in landfills and does not require complex treatment techniques. It also has almost no germs, making it safe to dispose of.

7: Fecal Sludge: Sludge from pit latrines, onsite sanitation systems, and septic tanks are what this is. It contains human excreta, solid wastes, urine, water, and any other substance that could be disposed of in sanitation systems' pits, vaults, or tanks.

Vacuum trucks are used to transfer faecal sludge to specialized faecal sludge treatment plants. Sludge can be used for irrigation, as a soil conditioner, or in the manufacture of biogas, biodiesel, charcoal, powdered industrial fuel, and electricity after treatment.

8: Industrial Wastewater Sludge:This is the sludge that is collected from warehouses, manufacturing plants, and other companies. Heavy metals, bacteria, and other chemicals are present in high concentrations, which can leach out if the sludge is not properly controlled.

The toxins in the sludge have the potential to harm both the environment and humans. As a result, thorough and meticulous treatment is required before it is disposed of on land.

For sludge treatment procedures, consult expert engineers from Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.