What are the current conceptions of Biological Trickling Filters?

One style of wastewater treatment system is a trickling filter.

It is made out of a continuous bed of rocks, coal, sand, slag, polyurethane foam, sphagnum peat moss, ceramic, or silicone media, over which sewage or other wastewater runs downstream, generating a layer of microbial slime (biofilm) to form and cover the surface of media. Splashing, diffusion, and either forced air flowing through the bed or spontaneous convection of air if the filter media is porous sustain aerobic conditions.

The cleansing of sewage or other wastes with trickling filters is one of the oldest and most well-known treatment methods.A trickling filter is also known as a trickling bio-filter, a bio-filter, or a biological trickling filter. Roughing filters, intermittent filters, packed media bed filters, alternative septic systems, percolating filters, attached growth processes, and fixed film processes have all been used to characterise these systems.

What is a Biofilm?

The bio-film that occurs in a trickling filter may expand to be several centimetres thick and is often a gelatinous matrix containing several species of bacteria and amoeboid protozoa, annelids, round worms and insect larvae, and other micro fauna. This is in stark contrast to several other bio-films, which can be as thin as 1 mm.

Aerobic and anaerobic zones can coexist within the biofilm's thickness, enabling both oxidative and reductive biological activity. At certain times of year, particularly in the spring, fast development of organisms in the film may cause it to become excessively thick and slough off in sections, resulting in "spring slop."

Elements of bio trickling filter:

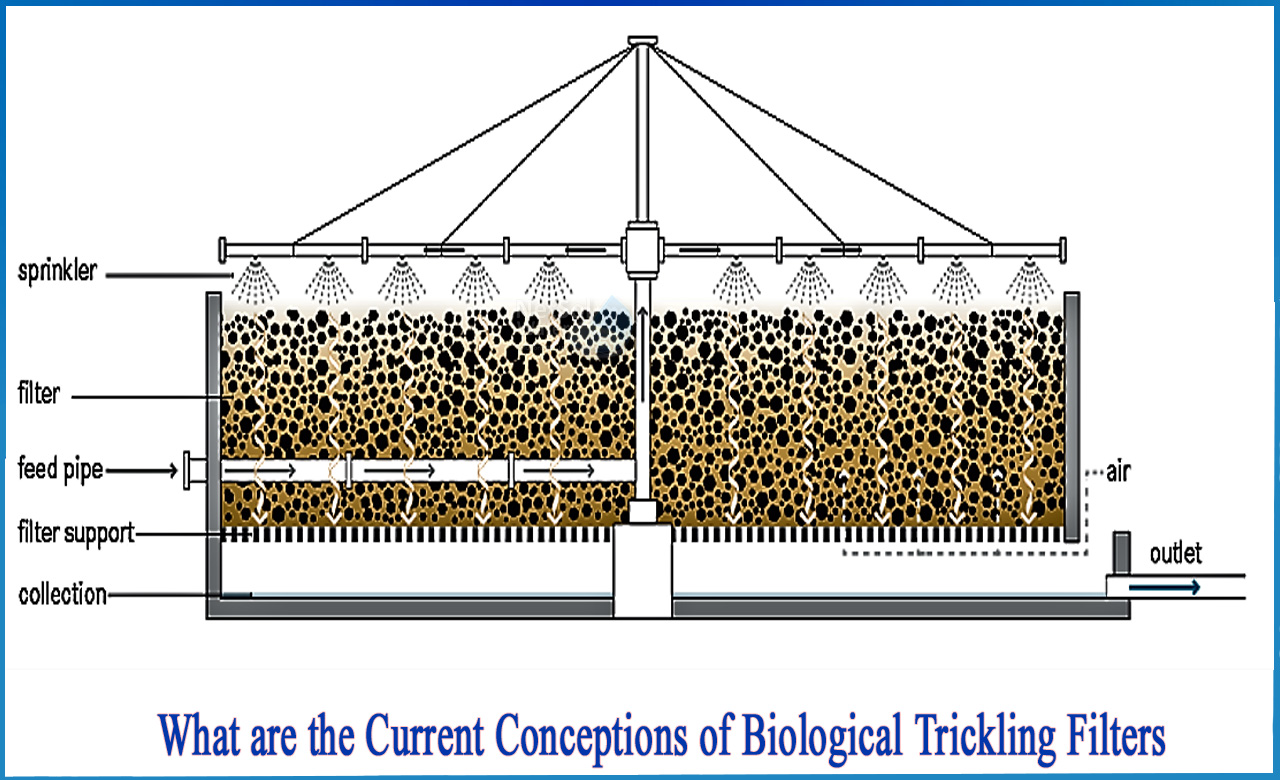

The following are typical elements of a comprehensive trickling filter system:

- a bed of filtration process that promotes and develops a layer of microbial slime;

- an enclosure or container that houses the bed of filter medium;

- Distributing the flow of wastewater over the filter medium.

Design of trickling filter

The standard trickling filter is circumferential, measuring between 10 and 20 metres wide and 2 to 3 metres deep.

A circumferential wall, commonly made of brick, houses a bed of filter media, and is supported by an under-drain foundation. These under-drains remove liquid that passes through the filter media while also allowing unrestricted flow of air up through the filter media.

A spindle mounted in the middle above the top of the filter media supports two or more horizontal perforated pipes that extend to the media's edge. The holes on the pipes are oriented to allow an equal flow of liquid throughout the whole surface of the media and to allow the entire assembly to revolve around the central spindle when fluid passes from the pipes.

Trickling may employ a variety of filter media to sustain the biofilm. Coal, pumice plastic matrix material, open-cell polyurethane foam, gravel, sand, and geotextiles are the most often employed media types. The ideal filter media maximises surface area for microbial attachment, wastewater retention duration, permits air passage, resists clogging, is mechanically strong in all weathers, allows walking over the filter, and does not decay. Some residential systems necessitate the use of forced aeration devices, which raises cost and operational expenses.

Benefits of bio trickling filter

- Appropriate for places where extensive expanses of land are not accessible for land intensive treatment systems;

- Depending on the medium employed, effective in treating large amounts of organics.

- Power needs are minimal.

- Suitable for small to medium-sized populations.

- Reduce soluble BOD-5 in application wastewater quickly.

- Long-lasting process components.

For more information, contact Netsol water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.