What are the advantages of Electrocoagulation in WWT?

Electrocoagulation is a wastewater treatment process that entails the operation of a low voltage, direct electric current and sacrificial metallic electrodes, commonly aluminium or iron, to destabilize water pollutants that are already suspended, emulsified, or dissolved. It is a small continuous-operation device that uses a specifically built reactor with metal plates or metallic electrodes. This method produces high amounts of cations, which destabilise remaining pollutants in water, forming complex hydroxides that can adsorb contaminants and form aggregates or flocs. Gas, on the other hand, develops, causing turbulence and pushing floc to the surface.

Chemical oxidation, which oxidizes metals and non-toxic contaminants while also significantly reducing COD and BOD, is another fantastic benefit of the electrocoagulation process.

Advantages of Electrocoagulation (EC)

When compared to alternative technologies, an electrochemical process offers the following advantages:

1: In EC process, both process and wastewater can be treated;

2: It can handle a broad variety of pollutants;

3: The operation makes use of simple and safe equipment’s;

4: Typically, no chemical treatment is required;

5: Electrocoagulation-treated waters may usually be reused, reducing waste.

How does Electrocoagulation (EC) work?

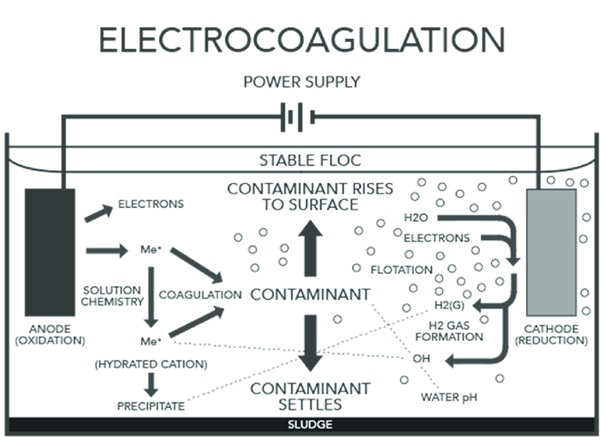

As we know that, Electrocoagulation (EC) is an electrochemical water treatment technology that is employed in many different sectors using an electrical charge to keep contaminating particles, ions such as heavy metals, and colloids in solution, the method destabilises and aggregates them. To destabilise the charges, the technique generally uses an anode and a cathode, both of which are stimulated by a DC power source. This procedure separates flocculated particulates from water, allowing them to be removed and replaced with pure water.

Stages of Electrocoagulation (EC) in Water/Wastewater Treatment

The electrochemical process is complicated, yet it is well understood. It is divided into three stages, each of which includes chemical and physical events.

Stage 1: Electrolytic oxidation and in-situ coagulant formation

The sacrificial electrode (usually iron or aluminium) is electrolytically oxidized, resulting in the creation ofOxides, aluminium hydroxide (a polymeric hydroxide generated when aluminium hydrolyses) and oxyhydroxides.

Stage 2: Destabilization of contaminants, emulsions, and particulates

1: Ions produced by the sacrificial electrode's oxidation interact to compress the diffuse double layer surrounding charged contaminating species;

2: Ions created by the electrochemical dissolution of the sacrificial electrode neutralize ionic species in process and wastewaters, reducing electrostatic interparticle repulsion;

3: When inter-particle repulsion is reduced, van der Waals attraction takes over, causing coagulation.

Stage 3: Formation of floc through aggregation of destabilised phases and particulates

1: Active surfaces for the adsorption of contaminating species are provided by oxides, hydroxides, and oxyhydroxides;

2: Floc generated by coagulation entraps and connects colloidal particles that remain in the aqueous medium;

3: At the anode, electrolyzed water creates small bubbles of oxygen, and at the cathode, small bubbles of hydrogen. The bubbles attract flocculated particles, causing them to float to the surface.

Conclusion

Electrocoagulation is a straightforward procedure that requires only basic equipment. Because the electro coagulated flocs contain less surface water, are acid-resistant, and more stable, they can be separated more easily by filtration. Furthermore, it is a low-cost technology that requires little investment and upkeep. In addition to being a technology for treating wastewater, it has also become a highly attractive process to use before reverse osmosis since it facilitates the desalination of the water to be treated.

Netsol Water has the solution to the electrocoagulation water treatment issues. To know more about how this technology eases your wastewater treatment procedures, keep-up with Netsol and learn how we capitalise on the best aspects of classic electrocoagulation, solve its challenges, and provide a totally different and superior technique.

Make a phonecall at +919650608473 or contact via email at enquiry@netsolwater.com for further consultation or product purchase related query.