In modern cities and towns, the proper management of wastewater is vital for keeping a healthy and clean environment. Sewage pump stations and lift stations play an imperative part in this handle, guaranteeing that wastewater is effectively transported from lower-lying regions to treatment stations. These stations are a basic portion of the general wastewater framework, and their smooth operation is basic for avoiding natural contamination and open wellbeing dangers.

What are Sewage Pump Stations and Lift Stations?

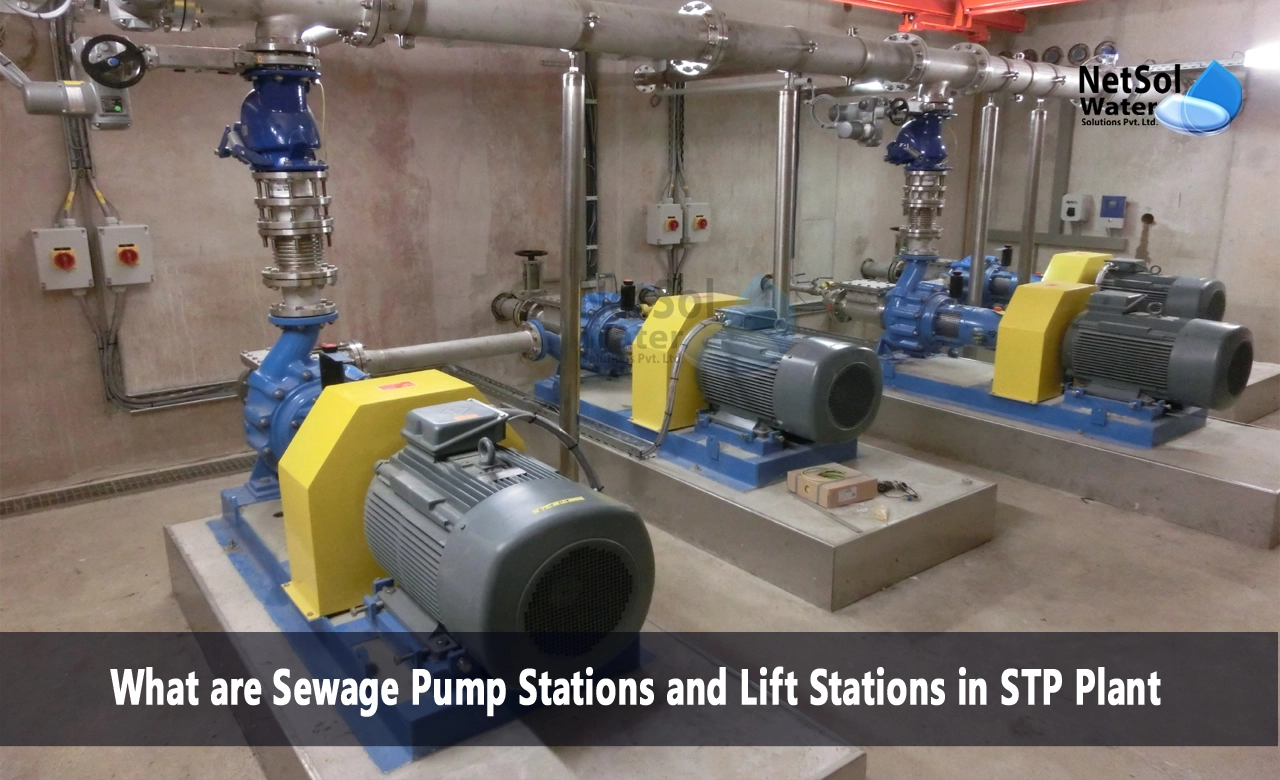

Sewage pump stations and lift stations are stations planned to move wastewater from lower rises to higher heights, overcoming gravity and permitting the wastewater to proceed its travel to treatment plants. These stations are ordinarily found in ranges where the territory or the format of the sewer framework makes it impossible for the wastewater to stream actually by gravity alone.

Sewage pump stations are regularly larger facilities that handle wastewater from different sources, such as private regions, commercial foundations, and mechanical stations. They are prepared with effective pumps that can move huge volumes of wastewater over critical separations.

Lift stations, on the other hand, are smallerstations that are planned to handle wastewater from a more localized range. They are commonly found in private neighborhoods or little commercial locale, where the sewage lines are not profound sufficient to permit for gravity stream to the most sewer framework.

Components of Sewage Pump Stations and Lift Stations

Both sewage pump stations and lift stations share comparative components, in spite of the fact that their sizes and capacities may shift. Here are a few of the key components found in these stations:

1. Wet Well:

Usually a deep, underground chamber where approaching wastewater is collected. The damp well acts as a brief holding region for the wastewater some time recently it is pumped out.

2. Pumps:

These are the heart of the sewage pump station or lift station. Capable pumps are utilized to lift the wastewater from the damp well and release it into the sewer framework or a drive fundamental (a pressurized pipe that transports the wastewater).

3. Control Frameworks:

Modern control frameworks are utilized to screen and direct the operation of the pumps, guaranteeing they work effectively and react to changes in wastewater stream.

4. Back-up Control Supply:

To guarantee nonstop operation amid control blackouts, sewage pump stations and lift stations are regularly prepared with back-up control supplies, such as generators or battery banks.

5. Ventilation Frameworks:

Appropriate ventilation is basic in these stations to expel odors and keep up a secure working environment for upkeep staff.

Operation and Upkeep

The operation and support of sewage pump stations and lift stations are significant errands that require specialized information and mastery. Regular inspections, preventive upkeep, and opportune repairs are vital to guarantee these stations work dependably and productively.

Prepared specialists and administrators are mindful for observing the hardware, checking for any potential issues, and tending to them instantly. They too perform routine tasks such as cleaning the damp well, keeping up the pumps, and guaranteeing the control frameworks are working accurately.

Appropriate upkeep also includes overseeing the stream of wastewater to avoid over-burdening the framework, which can lead to reinforcements and potential natural risks. This may include planning with other components of the wastewater framework, such as treatment plants and sewer mains, to guarantee smooth operation all through the complete framework.

Environmental Considerations

Sewage pump stations and lift stations play a basic part in ensuring the environment by anticipating the release of untreated wastewater into water bodies and other touchy ranges. In any case, these stations themselves can moreover have natural impacts in the event that not legitimately managed.

Odor control could be a critical concern, as the collected wastewater can discharge obnoxious odors that can be a nuisance to adjacent inhabitants and businesses. Progressed odor control frameworks, such as biofilters or chemical scrubbers, are regularly utilized to relieve this issue.

Commotion contamination is another potential natural effect, particularly in residential zones. Appropriate sound covers and noise-reducing measures are executed to play down unsettling influences on the encompassing community.

Moreover, measures are taken to prevent accidental spills or floods, which may lead to water contamination and potential wellbeing dangers. This incorporates normal maintenance, emergency reaction plans, and reinforcement frameworks to contain and relieve any episodes.

Vitality Effectiveness and Supportability

In a long time, there has been a developing accentuation on progressing the vitality effectiveness and supportability of sewage pump stations and lift stations. These stations can be significant consumers of power due to the vitality required to function the pumps and other gear.

To decrease vitality utilization and minimize their natural impression, numerous facilities are actualizing energy-efficient innovations and hones. These may incorporate:

1. Variable Speed Drives:

These progressed engine control systems allow pumps to work at ideal speeds based on the stream of wastewater, diminishing vitality utilization amid periods of lower request.

2. Effective Pumps and Engines:

Replacing more seasoned, less effective pumps and engines with more current, more energy-efficient models can lead to noteworthy vitality investment funds over time.

3. Renewable Vitality Sources:

A few stations are investigating the use of sun-based boards, wind turbines, or other renewable vitality sources to supplement or supplant their dependence on grid-supplied power.

4. Checking and Control Frameworks:

Progressed observing and control frameworks can optimize the operation of the pumps and other gear, diminishing vitality squander and progressing in general effectiveness.

By grasping energy-efficient innovations and hones, sewage pump stations and lift stations can diminish their natural affect and contribute to a more feasible wastewater administration framework.

Conclusion

Sewage pump stations and lift stations are fundamental components of advanced wastewater foundation, playing a pivotal part in guaranteeing the correct administration and treatment of wastewater. These stations overcome the challenges postured by shifting territory and height, permitting wastewater to be transported effectively to treatment plants.

Whereas frequently inconspicuous and overlooked, the smooth operation of sewage pump stations and lift stations is crucial for securing open wellbeing and the environment. Customary maintenance, skilled staff, and adherence to natural controls are key to guaranteeing these stations work dependably and economically.

As communities proceed to develop and urbanize, the significance of these stations will only increase. Contributing to their modernization, vitality effectiveness, and natural supportability will be vital for meeting the wastewater administration needs of long-term while minimizing their natural affect.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.