What are main Coagulation Chemicals used in Chicken Processing WWT?

Poultry slaughterhouse wastewater (PSW) is often disposed of by releasing it into waterways, municipal wastewater treatment works (MWTWs), or spreading it across grasslands and croplands. The PSW, on the other hand, is detrimental to human health and the environment due to its hazardous character.

To attain zero effluent emissions, the poultry sector must use cutting-edge technology that minimize freshwater consumption and boost reuse techniques.

Wastewater from poultry Industrial processes

Large volumes of high-quality water are required for process cleaning in the poultry processing industry. Due to the presence of organic material such as blood, fat, meat, and excreta, process wastewater created during these operations often has a high biochemical and chemical oxygen demand (BOD and COD). Furthermore, process wastewater may include significant quantities of nitrogen, phosphate, and residues of chemicals used for washing and disinfection, as well as pathogens such as salmonella and campylobacter.

What are the Coagulants used?

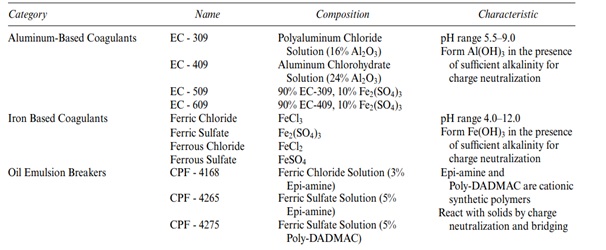

Compounds that enhance the coagulation of liquids into solids are known as coagulant chemicals. There are two types of chemical coagulants for wastewater treatmentviz.: Organic and inorganic

Coagulants are used in water/wastewater treatment to remove a wide range of harmful pollutants, including organic waste and pathogens, as well as inorganics and toxic element chemicals including phosphorous, fluoride and arsenic. They are frequently used as the initial stage in a pollution reduction plan for developing nations, particularly those with rapidly increasing metropolitan areas and no centralized wastewater treatment.

Coagulants are utilized in medical applications to cause blood clotting, in addition to being chemicals used in water treatment plants. They're also employed in the production of pulp, paper, and textiles, as well as in oil, gas, and mining activities.

Main chemicals used for WWTP in chicken processing_

A combination of 800 mg/L ferric chloride and 900 mg/L floccin 1115 would provide the best treatment, removing at least 98 percent of total suspended solids (TSS) and 97 percent of volatile suspended solids (VSS) while increasing water clarity by 97 percent. With a DAF recycle ratio of 40%, the flocculated particles may be transported to the surface.

Conclusion

A chicken processing plant's effluent resembles an oil emulsion with a high suspended solid concentration. Because of the size, charge, and particle weight of this slurry of fats, oils, greases, and tiny particles, it will remain in suspension. Coagulation is used to aggregate these particles into bigger sizes so that they can settle more rapidly or be more easily floated.

How can we help?

Feel free to contact Netsol Water with any queries you may have about custom-designing and manufacturing wastewater treatment plantsfor a variety of industries and applications. We can help you through the process of determining the best solution and determining a reasonable price for your individual wastewater treatment system requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.