What is faecal sludge?

Faecal sludge is the mixture of liquid and solid waste that builds up in on-site sanitation systems (OSS), such as septic tanks or sewage treatment plants. The collection, storage, or treatment of mixtures of excreta and blackwater, with or without greywater, results in a raw or partially digested slurry. The main parts of this are scum, wastewater, and sludge. It smells bad, looks bad, and has a lot of grease, grit, hair, debris, and harmful microorganisms in it.

Thus, the management of faeces requires collection, treatment, and appropriate disposal/reuse. Safe disposal of the treated sludge is a necessary component of effective faecal sludge management. Let’s understand what faecal sludge is and its treatment process with the process flow diagram.

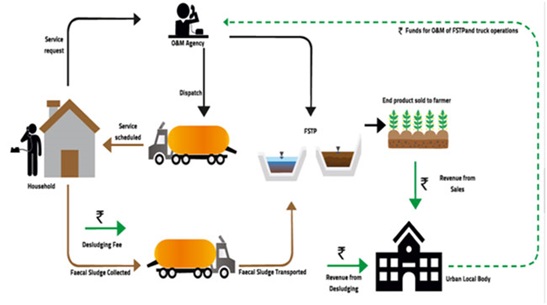

Collection of faecal sludge

Faecal sludge removal from on-site sewage treatment plants is secure. Different conditions frequently exist in urban settings that either make collecting easier or more difficult. Urban/small towns and cities have a wide range of OSS, where the rate of sludge output varies and affects collection.

Transportation of faecal sludge

It is used to move waste from the source to the treatment centre. De-sludging trucks, mounted tractors and hoover trucks are most frequently utilised, to collect the sludge in metropolitan parts of India. Transport vehicles in India come in a variety of sizes and designs and are often built locally.

Treatment of faecal sludge

Sludge can be treated by a number of methods, depending on what is appropriate for the area. There are numerous solutions that can be wisely chosen while taking elements like cost and reusability into account. The choice of treatment option is also influenced by the type and quantity of septage de-sludged from on-site systems.

Some frequent and adaptable treatment strategies include dewatering, co-composting with solid waste, co-treatment at STP, land application, and natural treatment methods.

What is faecal sludge management?

The collection, transportation, and treatment of faeces from septic tanks or other onsite sewage treatment systems is known as faecal sludge management (FSM). Faecal sludge, which is disposed of in pits, tanks, or vaults of onsite sanitation systems, is a mixture of human excreta, water, and solid wastes such as toilet paper or other products.

How is faecal sludge treated? What is the process/technology of faecal sludge treatment?

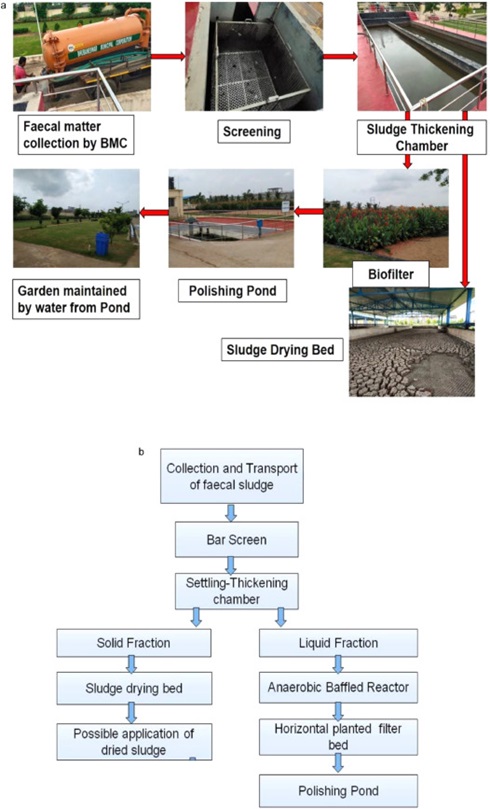

The following processes are required for the treatment of faecal sludge:

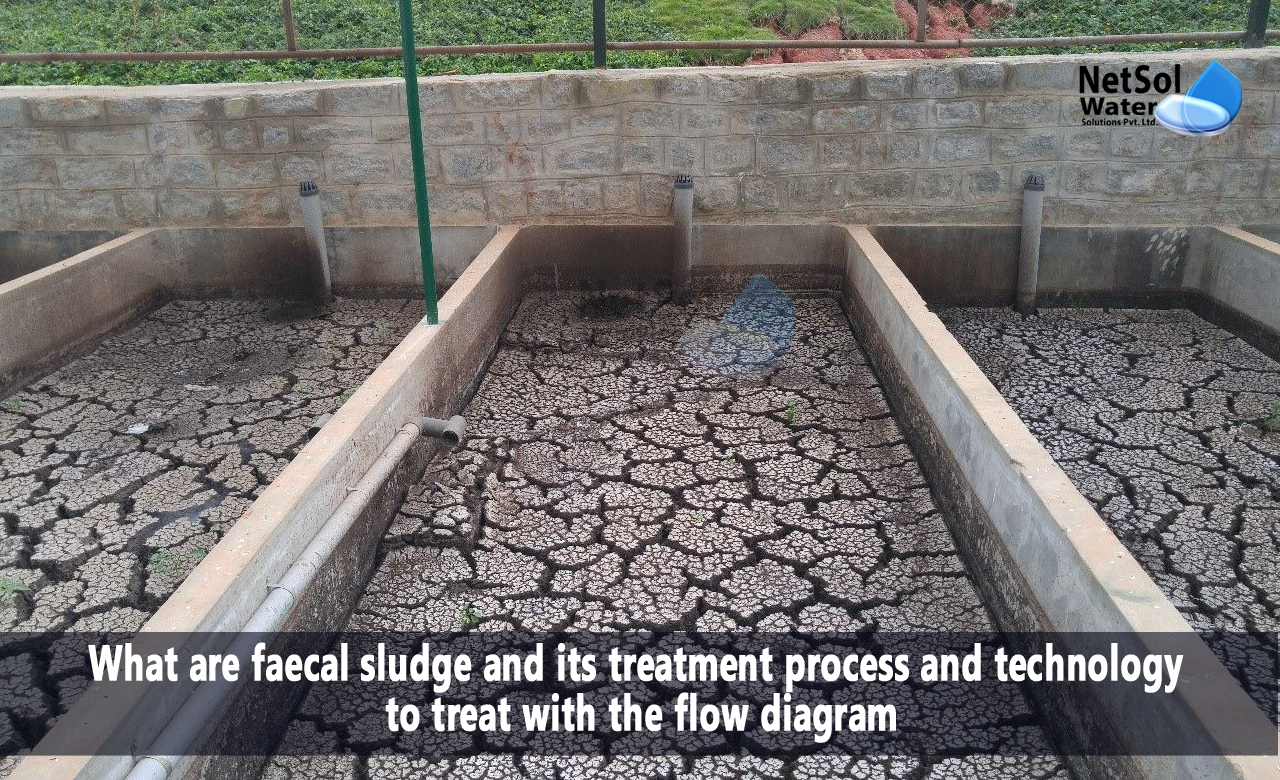

Sludge receiving chamber and screening

The cesspool vehicles gather the faecal sludge and dispose of it in the sludge receiving chamber. Then, sludge is routed via various-sized bar screens to a tank that contains a settling-cum-thickener. These are used to separate plastic, large floating items, and other contaminants from faecal sludge. The grit is also separated from the faecal sludge by gravity.

To retain large solid particles, bar screens are positioned vertically or obliquely with respect to the incoming flow. To avoid solids deposition, the hydraulic characteristics of the sludge receiving chamber should be adequate. For alternate loading and cleaning operations, two receiving chambers will work well.

Sludge thickening tank or ST tank

The Settling-cum-Thickening Tank (ST Tank) largely permits heavier septage particles to sink to the bottom of the tank due to gravity, while lighter particles such as fats, oils, grease, and water remain above.

ST Tanks have a rectangular shape with an outlet on the tank's opposite side for the supernatant's evacuation. To stop the separation of scum and the scouring of settled sludge, a baffle can be put at the outflow. The tank primarily has two compartments, though it occasionally has three compartments that can be loaded with septage in different ways.

Each tank is loaded for at least a week before the sludge is allowed to thicken and settle, stabilising the settled solid during the anaerobic sludge digestion process. Then, at regular intervals, thickened sludge is injected to the sludge drying bed. If the sludge is not thick enough, it is often removed using a vacuum truck, an excavator, or pumps.

Anaerobic baffled reactor (ABR) for faecal sludge treatment

The ABR is an airtight reactor made up of a number of chambers where liquid enters by gravity, from the settling cum thickening tank and runs through the baffles. Its design guarantees that the wastewater has more time to interact with the sludge, increasing efficiency. It decreases the pathogens and degradable organic matter in the faecal sludge, but not the nutrients. The chamber is kept totally closed, and vent pipes are used to discharge the gases produced within.

Additionally, ABR needs few months to get going because it takes time for anaerobic microorganisms to grow and adapt. The level of scum and sludge in the ABR must be checked, and dangerous chemicals shouldn't be dumped into it.

Also, sludge build-up is typically cleared every one to three years. With an input range of 2-200 m3/d and 3–8 chambers, the typical HRT for an ABR is 2–3 days. For maintenance purposes, access must be possible to every chamber. The amount of biogas produced is so small that it is not collected.

Bio-Filter technology for faecal sludge treatment

The faecal sludge treatment facilities can also use "Bio Filter" technology, which has a daily capacity of 10 Kilolitres (KLD) of faeces sludge treatment. The processes that make up this method are polishing, anaerobic digestion, and vermifiltration. Vermifiltration using earthworms processes waste quickly, without odour or the requirement for desludging.

Comparing vermifiltration to more traditional sanitation, it is said to be a more effective technology. Vermicompost is created as a result of earthworms helping to stimulate the decomposition of organic waste. To establish a stable population in the vermifilter, the worms simply require access to air, water, and organic material.

Biological Digester for faecal sludge treatment

In the absence of oxygen, microorganisms break down biodegradable material through a variety of processes known as anaerobic digestion. To lessen the organic load from faeces sludge, these tanks are utilised. A specially created bacterial culture that consumes organics from faecal sludge is present in this tank.

The thickened sludge is then applied to beds containing earth worms and bacterial cultures, which offer a favourable habitat and breathing zone for earthworm development and reproduction. This tank is used to separate the liquid stream coming from anaerobic digesters from the leftover solids. At this point, all unpleasant odours have been fully eliminated. Earthworms devour the trapped solids and turn them into vermicompost, which lowers the organic burden. The tank's bottom is where the liquid stream exits and is kept.

Use of Activated Carbon Filter, Pressure Sand Filter, and Disinfection for faecal sludge treatment

This polishing unit is offered to get rid of any colour or smell that remains after additional treatment. Chlorination, ozonation or UV is used to disinfect treated wastewater, making it suitable for human handling and disposal.

Reuse vs. disposal

In some procedures like composting, humus is created that can be utilized to improve soil. Thus, sludge can be used as a source of energy as well.

Process Flow-chart for faecal sludge treatment

Benefits of faecal sludge treatment

· Natural

· Economic

· Eco-friendly

· Capital and O&M cost is low

· It can handle high loading

· Less energy is required

· Un-skilled labour can operate as well

Learn more about our options for treating faecal sludge

Faecal sludge is harmful to the environment and to people's health. To prevent pollution from sludge, poisonous and dangerous substances that are released into the water must be eliminated.

That is why; Netsol Water provide various sewage treatment solutions for treating sewage and faecal sludge. We also provide outstanding wastewater solutions for any sector with high-quality, as well as dependable products and a knowledgeable engineering group. To find out more, get in touch with us at +91 9650608473 or email at enquiry@netsolwater.com.