What are carbon adsorbers?

Volatile organic compounds (VOCs) and several sulphur-containing chemicals, including mercaptans and hydrogen sulphide, are removed from vapour streams via carbon adsorption. The performance of adsorption systems is influenced by a variety of parameters, including the type of carbon used, the nature of the contaminant, gas flow rates, and temperature.

Adsorption of VOCs and other gas-phase contaminants: Highly effective oil vapour, H2S, and other odour removal

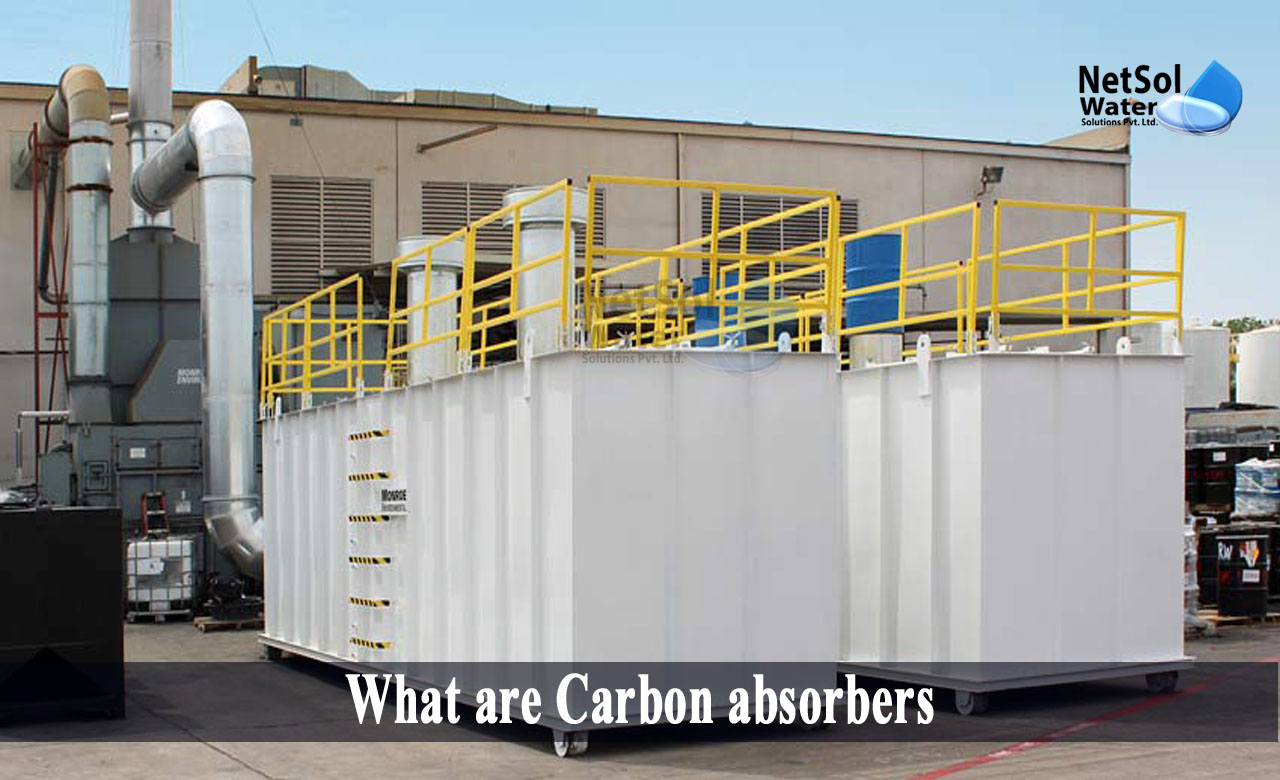

Carbon adsorbers are produced by Netsol for the physical and chemical adsorption of gas-phase contaminants. Pollutant gas molecules adhere to porous solid surfaces during adsorption, which happens as the contaminated air stream passes over them.

Our activated carbon adsorber is very effective at removing gas phase hydrocarbons, H2S and other odours, oil vapours, and VOCs.While, chemical adsorption requires the creation of chemical bonds, physical adsorption depends on intermolecular interactions.

For adsorbers using a variety of different adsorbent materials in bulk-packed fixed bed designs, which are either regenerative or non-regenerative filter bed designs, Netsol provides comprehensive in-house manufacturing and engineering services. Engineers and designers in our staff will assess each application separately, and choose the best design parameters for each installation.

Applications of Carbon Adsorbers

· Removing VOCs and recovering solvents.

· Industrial emissions from removing grease, spray painting, coating paper, plastic film, metal foil, rubber, and printing.

· Odour removal from head-works, digesters, and sludge dewatering processes at municipal wastewater treatment plants, as well as other odours.

Types of carbon adsorbers

Deep Bed Adsorber: It is a vessel that has one or more deep beds arranged in sequence, either horizontally or vertically.

Airflow between two parallel beds in either a horizontal or vertical configuration runs between them, allowing for a higher airflow since there is a larger pathway for the gas' initial contact, with one of the adsorbent beds.

Multiple Adsorber Vessel System: Two or more distinct adsorber vessels provide uninterrupted adsorption and regeneration, by directing air flow through one or more vessels for the adsorption of pollutants. The other vessels are regenerated with steam.

Flow moves parallel through numerous detachable carbon trays in a carbon tray adsorber. When the pellets are saturated, each tray of activated carbon can be removed and refilled.Air is channelled via pleated or canister-style filters that may be quickly changed out, as they become saturated with carbon.

Features of the Carbon Adsorbers

· Various adsorbents, including carbon, zeolite, and synthetic polymers are used.

· Effectiveness is around 99.9%

· Construction materials include mild steel, stainless steel, PVC, FRP, and others.

· Electrical controls and full instrumentation are provided.

· It is resistant to corrosion.

How can we assist further?

Netsol Water provides expert guidance and technical support for all air, water and wastewater related issues. Our certified specialists have worked on a wide range of carbon adsorbers, in a variety of sectors.

We will assist you in ensuring that your industry complies with all authority laws. We are the experts, from design to installation, to support and maintenance.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.