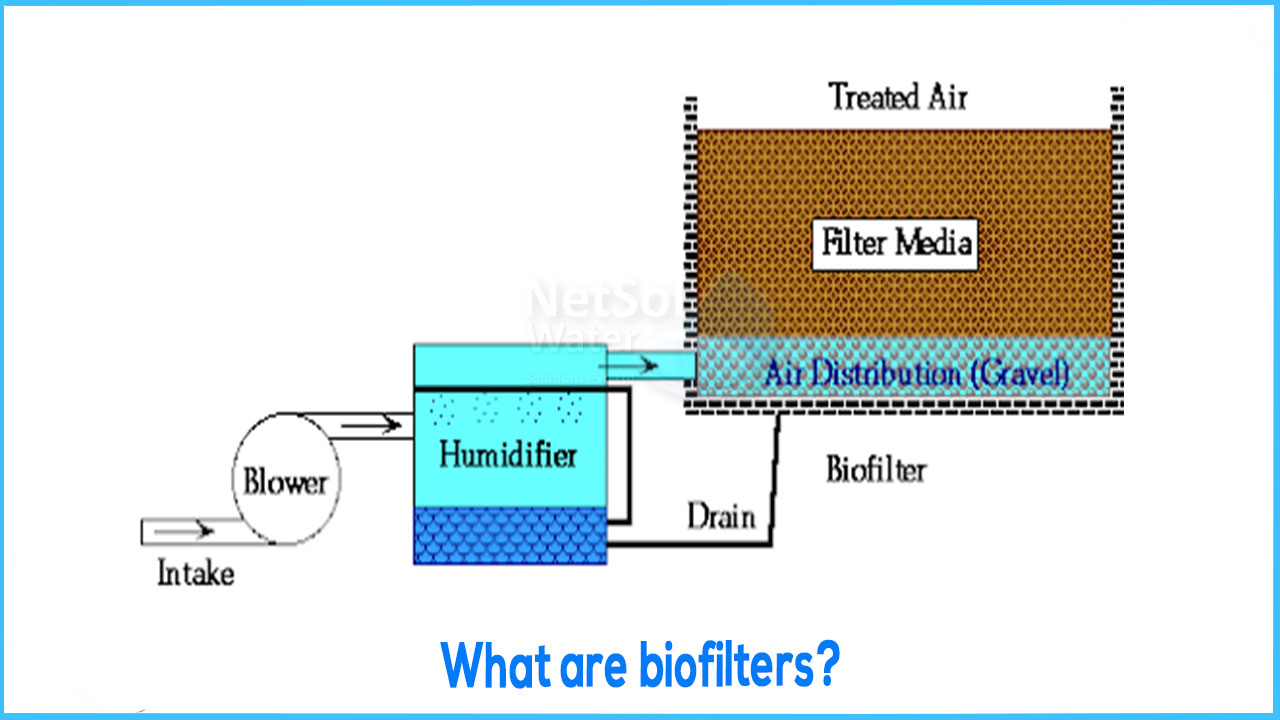

What are biofilters?

The term biological filters or bio filters used in wastewater treatment includes all the processes that combine biological purification through attached growth with the retention of suspended solids.This technique applies thin biological films that are regularly renewed by washing (12 to 48 hours cycles). This provides a biomass with a concentration and, especially, an activity that are higher than for activated sludge. Compared with activated sludge, this technique has the following main advantages:

- 1. Space saving, by eliminating the clarification stage. By virtue of the system’s compact nature, its structures can more easily be covered over, controlling olfactory and noise nuisances and producing aesthetically acceptable plants;

- 2. no danger of leaching because the biomass is attached to a support that is used to adapt to flow rate variations;

- 3. appropriate for use with diluted wastewater, as water velocities can be very high without adversely affecting treatment;

- 4. Modular construction and easy to automate (comparable to drinking water plant filter batteries)

BOD REMOVAL

With medium concentration primary settled urban wastewater, BOD loadings of 2 to 4 kg m–3·d–1 will reliably produce a BOD of less than 25 mg · L–1. This figure can even exceed 6 kg BOD · m–3 · d–1 with diluted water (BOD below 70 mg · L–1).These applied loadings will vary depending on temperature. On the other hand, the granulometry of the material used has little effect on BOD removal.

NITRIFICATION

Maximum nitrification capacity CVN max. (in kg N-NH4·m–3·d–1) is significantly affected by temperature, like any nitrification process, and also by the readily assimilated carbon/ N-NH4+ ratio and, therefore, by upstream treatment. When partial nitrification is required (less than 70% NK efficiency), only one bio-filtration stage will be needed. When advanced nitrification is required (80 to 96% NK efficiency), advantage can be gained from removing as much carbon as possible over a first stage.

REMOVAL SUSPENDED SOLIDS

Bio-filter performance depends on the choice of material, on the suspended solids concentration in the influent and on hydraulic loading in the filtration stage. For water to be treated that has an initial suspended solids content of less than 100 mg · L–1, suspended solids removal efficiency will vary from 75 to 85% at water velocities of 3 to 6 m · h–1.

EXCESS SLUDGE PRODUCTION

Suspended solids retention and of an increased heterotrophic and autotrophic biomass creates excess sludge production. Excess sludge production is characteristic of medium loading biological systems, allowing for enhanced suspended solids collection. Between two washes, retention capacity normally ranges from 2 to 4 kg suspended solids · m–3 of matter. These suspended solids are collected in the form of wash water having an average concentration of between 200 to 800 mg · L–1 depending on the application. These suspended solids are either returned to a point upstream from primary treatment or processed separately by sedimentation or floatation. It should be noted that the sedimentation and dewatering capacity of this sludge is far better than that of activated sludge.

PROCESS AIR VELOCITY

The process air velocity must meet the following oxygen demands: carbon oxidation, nitrogen N-NH4 oxidation and endogenous respiration. Depending on application conditions, process air velocity can vary from 5 to 25 Nm3 · m–2 · h–1,or more in tertiary nitrification carried out at high temperature levels