Every day, wastewater is discharged into India's sewer system from homes, workplaces, schools, and factories. In the majority of the city, a wastewater resource recovery facility receives wastewater as well as storm water runoff from streets, walkways, and rooftops through the combined sewage system.

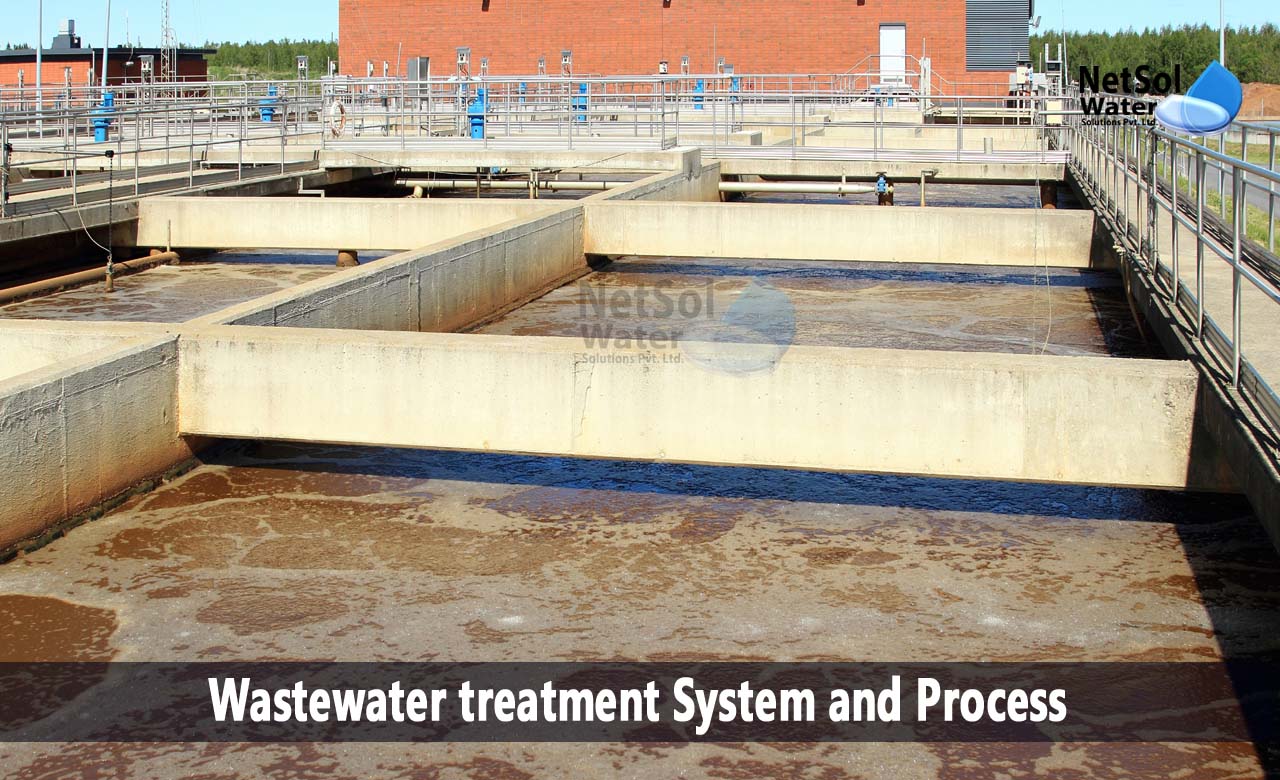

Wastewater is treated in five main steps at Wastewater Resource Recovery Facilities, which closely resemble how wetlands, rivers, streams, and lakes naturally filter water. Let’s discuss the wastewater treatment processes and various systems used in its treatment.

What is Wastewater treatment System and Process?

1: Preliminary Treatment

Incoming wastewater from the sewage system, referred to as influent, enters the plant several levels below ground. Wastewater is filtered by bar screens as it enters the plant to remove debris like leaves, twigs, and plastic bags, food wrappers, bottles, and sanitary wet wipes.

The trash and debris are gathered by us and transported by truck to landfills. The effluent from the screens is then pumped up to the facility's surface level, by the main sewage pumps.

2: Primary Treatment

The wastewater then moves into primary settling tanks, where the water flow is slowed down. These are removed from the surface of the tanks. The lighter solids float including oil and small pieces of plastic.

Sludge or the heavier organic substances such as waste products and paper fibers, starts to settle in the meantime. We take out this main sludge for thickening and digesting from the bottom of the settling tanks.

3: Secondary Treatment

In order to create a favourable habitat for the oxygen-loving microorganisms that are naturally present, in the sewage during secondary treatment, air is added to aeration tanks. These beneficial microbes devour a significant portion of the organic matter in the wastewater, resulting in heavier particles that are simpler to eliminate.

The heavier sediments then sink to the bottom of the final settling tanks, where the aerated wastewater is being processed. For thickening and digesting, we extract the majority of this secondary sludge and mix it with the primary sludge.

We transfer a portion of the secondary sludge back to the aeration tanks, to process incoming wastewater and assist maintain the proper balance of beneficial bacteria.

4: Disinfection

Add sodium hypochlorite, a substance also included in household bleach, to wastewater to disinfect it and get rid of any lingering pathogens. The cleaned-up wastewater, also known as effluent, is then discharged into nearby waterways.

5: Sludge Treatment

To further separate the water from the solid material after primary and secondary treatment, thicken the sludge that was collected. We put the thickened sludge into digesters, which are tanks that keep a low-oxygen environment at a temperature of about 98°F. The sludge is broken down by organisms that flourish in an anaerobic environment, and a large portion of the material is transformed into biogas, also known as methane gas.

The treated sludge undergoes dewatering, which uses giant centrifuges to separate the water from the solids, after around 15 days. Biosolids, or the residual solids, can be composted, applied to agricultural soils, or processed further for various advantageous uses.

Conclusion

Water quality and public health must be protected, hence, wastewater must be filtered or treated to some extent. To variable degrees, suspended particles and biodegradable organics must be eliminated. Bacteria that are harmful must be eliminated.

Nitrates and phosphates (plant nutrients), as well as neutralizing or removing harmful compounds and industrial waste, may also need to be removed. The level of treatment required for wastewater varies, depending on regional environmental factors and governmental regulations.

What do we offer?

Understanding need of wastewater treatment and water treatment techniques in India, a wide variety of wastewater treatment options which includes physical, chemical, and biological processes, are offered by Netsol Water.

Netsol combines cutting-edge technology with their years of experience to handle the most challenging, water treatment or wastewater treatment requirements of a wide range of clients, including small enterprises, corporations, and regional government agencies.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.