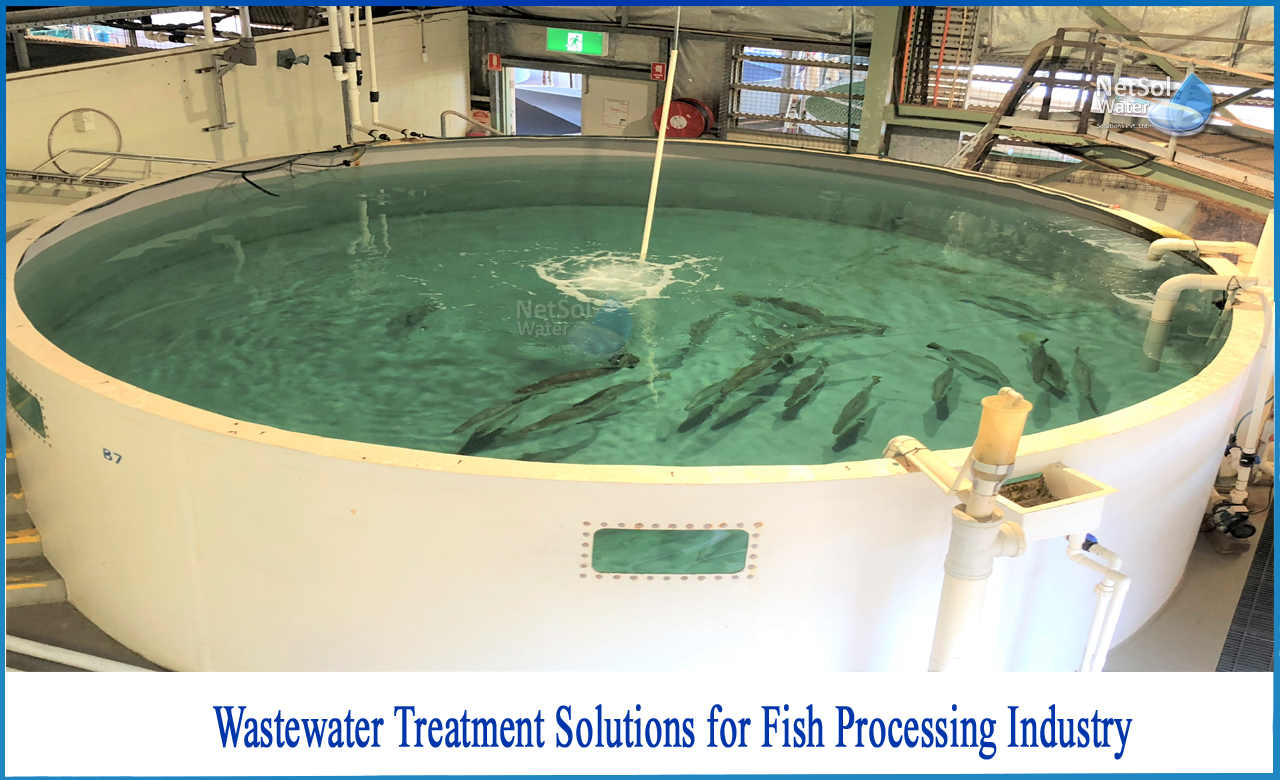

How to treat waste water in fish processing industry?

Many small processing plants make up the seafood business, with a few larger plants positioned near industry and population centres.

Mollusks (oysters, clams, and scallops), crustaceans (crabs and lobsters), saltwater fishes, and other sorts of seafood are all processed. Seafood processing facilities, like most processing industries, produce waste. Significant pollutants are in soluble, colloidal, and particle forms in wastewater.

The degree of contamination varies depending on the operation. The biochemical oxygen demand (BOD), fat, oil, and grease (FOG), and nitrogen content of waste water from seafood processing activities can be extremely high. The severity of the problem generated by these wastewater streams is difficult to generalise because the impact is dependent on the effluent strength, the rate of discharge, and the assimilatory capacity of the receiving water body. However, when defining the characteristics of a wastewater, critical pollutant criteria must be considered.

Wastewater Composition

Processing Water - Flow rates might vary dramatically depending on the plant's operations. Effluents can be divided into two types:

High salinity waste fluids resulting from products or the use of seawater in part of the process, and,

Low salinity waste waters resulting from the use of fresh water with no salinity produced as a by-product.

Cleaning Wastewater - Cleaning wastewater is typically generated by washing machines that come into direct touch with the product. Product leakage, pressing and brining, CIP effluents or equipment breakdown, and even operational errors are all examples. These effluents are plentiful and highly contaminated, necessitating additional treatment.

Sanitary Wastewater -Sanitary wastewater can be found in restrooms, shower rooms, and other public areas. Sanitary wastewater is comparable to municipal wastewater in composition and is typically piped straight to sewage treatment plants; however, it can be used as a nitrogen source for imbalanced effluents prior to additional aerobic treatment.

Seafood processing wastewater treatment

The wastewater generated during the processing of seafood fluctuates a lot from hour to hour. Obtaining a representative sample for the purpose of designing a treatment system might be difficult.

In the 1ststage of the design process, a single point sample is frequently all that is available. The 2ndphase, if possible, should be the hourly collection of 24 hours of effluents. This could help detect pollutants' peak loads, peak flows and flow durations.

The optimal time to take a sample is right before the water is discharged into the receiving body. In addition to analysing pollutants loads such as TSS, FOG, COD, BOD, and nutrients, doing jar tests to find the appropriate dosage and type of treatment chemicals is always a good idea.

The different processes are –

Equalization -An industrial effluent that has been properly equalised can give a more consistent and homogeneous flow to the flotation machine. Equalization also lowers hydraulic surging, which can have a negative impact on the system's performance. In some circumstances, EQ tanks can be sized to allow the flotation units to operate for specific periods of time.

Screening -Screening is one of the most cost-effective and straightforward wastewater treatment method. Self-cleaning mechanisms are sometimes provided. Because of their flow properties, tangential screens are less prone to clogging. The trapped solids are washed out of the screen into a collector in the upper section of the drum by a spray of water as the screened wastewater flows outside the drum. Screens used in the treatment of wastewater from seafood processing can eliminate anywhere from 30% to 80% of solids. This can minimise the pressure on following basic treatment stages like flotation.

Coagulation and Flocculation - Coagulation, flocculation, and flotation are three of the most efficient methods for removing fats, oils, and grease, suspended particles, and colloidal components. Coagulation is the insertion of oppositely charged ions or molecules to destabilise colloidal suspensions by neutralising surface charge. The production of huge stable flocs that either sediment or float is known as flocculation. Reagents that cause flocculation are known as flocculants that link together smaller coagulation flocs.

Conclusion

Contaminants such as TSS, FOGs, COD, BOD, and microbes are abundant in seafood processing effluent. TSS, FOGs, and microbes are the most unpleasant and environmentally unfavourable contaminants. The removal of these toxins might greatly minimise the industry's impact on nearby bodies of water, such as rivers, lakes, and seas.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.