A membrane bioreactor (MBR) is a procedure that combines a suspended growth bioreactor, and a microfiltration or ultrafiltration membrane unit. It is now commonly utilized in municipal and industrial wastewater treatment plants (WWTPs).

The effluent has less bacteria and virus content and is free of suspended particles, as compared to the activated sludge (CAS) process. As a result, only minimal disinfection is necessary.

As a result, the MBR process makes it simple to discharge treated effluent to sensitive receiving bodies, or to reuse it for uses like urban irrigation, utilities, or toilet flushing. It is also of a high enough standard to be fed directly to a reverse osmosis (RO) procedure.

What are the Uses and applications of membrane bioreactors?

Currently, MBR technology is widely utilized to treat a variety of wastewater streams, including landfill leachate, industrial wastewater, and municipal wastewater.

1) Treatment of municipal wastewater

MBR systems were initially designed with an emphasis on water reuse and recycling, for municipal wastewater treatment applications. Due to its small size, capacity to create reusable water, and ease of operation, the MBR is a perfect technique for recycling municipal wastewater in areas, with limited water and space.

2) Treatment of industrial wastewater

Alternative treatments like MBR are preferable for industrial waste streams, since they can contain large levels of organic matter and chemicals, which are particularly challenging to handle or decompose.

In fact, MBRs fully maintain the biomass, which allows for a higher richness of the bacterial and protozoa population, and favours the biodegradation of resistant materials such as herbicides, pesticides, etc.

3) Management of landfill leachate

MBRs have been used in a variety of different applications besides treating sewage, from municipal and industrial sources. Organic and inorganic chemicals are typically found in high amounts in landfill leachates.

Reverse osmosis and nanofiltration technologies, as well as other extra treatment steps for the removal of heavy metals and inorganics, have been employed successfully with MBR systems.

Our MBR services

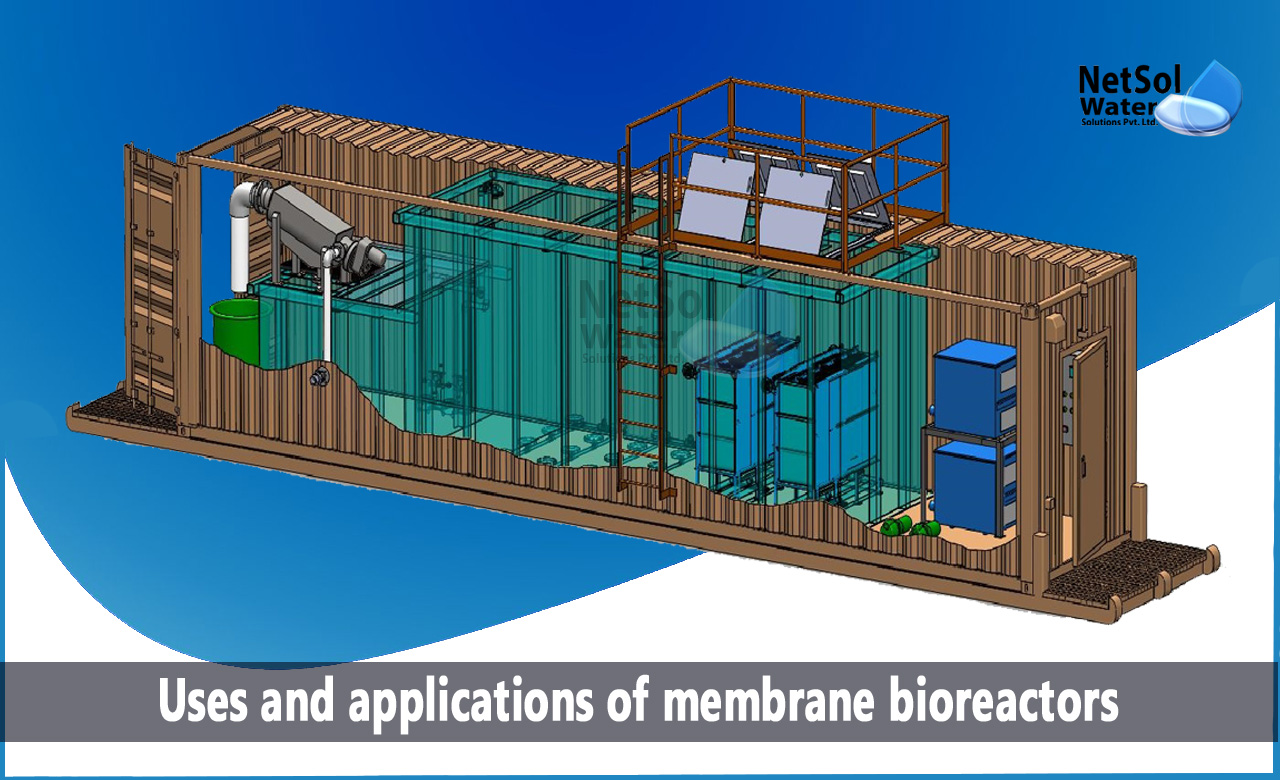

Netsol Water can provide a variety of technologically cutting-edge and cost-effective membrane geometries/configurations, to meet all of your needs. Depending on the nature of the wastewater and the infrastructure already present on the site, MBR systems can be offered as conventional packages or as custom solutions.

Reverse osmosis Plants from Netsol can be used to produce the highest-quality filtrate stream, by subjecting the produced effluent to one more polishing stage.

Get your STPs from us!

Your wastewater treatment needs can be satisfied with MBR's low-footprint, high-effluent solution. It can be utilized to construct brand-new, cutting-edge facilities as well as to upgrade current WWTPs.

We are happy to assist you as one of the few vendors who provide both submerged and side-stream membranes. Find the MBR solution that is best for your particular situation with the aid of our specialists. This is becoming more and more important in light of the severe effluent quality criteria, set by municipal rules that will go into force in the coming years.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.