Introduction on Dissolved Air Floatation

Although dissolved air flotation (DAF) is extremely effective at removing fats, oils, and grease (FOG) and total suspended solids (TSS) from wastewater, it is less effective at reducing biochemical oxygen demand (BOD). That may not matter in many places. In other words, it could lead to community issues or surcharges at publicly owned treatment works (POTW).

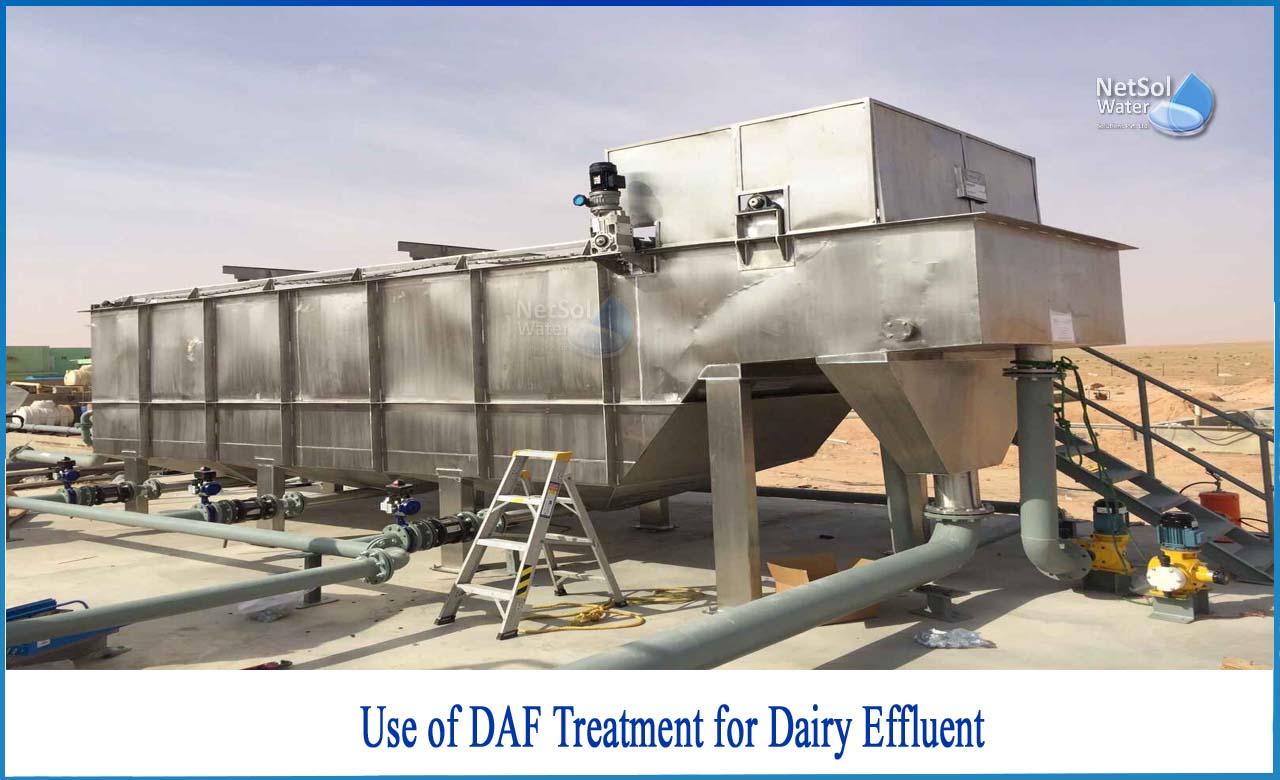

The onsite wastewater treatment process begins with a fine solids screening system. The effluent is then routed through an equalization (EQ) tank with mechanical mixing and aeration before entering a DAF system for final organic separation before discharge to the POTW. A polymer-assisted flocculation unit is included in the DAF system to coagulate organics prior to the air flotation tank.

Food production wastewater has the potential to carry ten times the organic load of municipal wastewater. Sewer and water utilities frequently can't keep up with the demand, and when they do, they charge accordingly. As a result, many businesses treat their wastewater entirely in-house.

Another option for plants is to do pretreatment in-house to save money on municipal treatment. Effluents from dairy production are particularly difficult to treat. Different types of effluent are produced at different times, resulting in large variations in the effluent stream. Dairy effluents, on the other hand, are typically distinguished by high temperatures, high organic loads, and a wide range of pH values.

What is the use of DAF Treatment for Dairy effluent?

Dairy effluent contains detergents and other chemicals used in the cleaning of milking equipment, as well as nutrients from animal faeces, urine, and milk. Although the amount of effluent discharged by a single dairy farm may be small, the cumulative effects of many dairies contributing to one catchment can be substantial. Small watercourses and drains still have ecological value and should be protected from stock because many species use them as routes to major waterways as well as places to spawn and hatch their young.

Waste-to-Energy

Because of the high organic load in food industry wastewater, it also contains enough potential energy to significantly reduce power bills. An increase in wastewater volume, either through increased production or collaboration with other dairy operations, would justify the addition of a waste-to-energy system in the future to further reduce production costs.

How does DAF systems work?

DAF systems function by dissolving air into wastewater. This produces thousands of micro-bubbles, aerating the wastewater. The suspended material in the wastewater floats and thickens as a result of this process. After that, the solids are separated for recovery or disposal. This is a critical step in the removal of solids from wastewater. Following that, the water is ready for further treatment and reuse.Effluent is typically treated and disposed of in one of three ways: discharge to surface water, pond soakage into the ground, or irrigation onto pasture.

What can Netsol Water provide?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, and ETP manufacture, among other services. We've made it our mission to save the planet. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish and treat wastewater to the larger extent as possible, thus minimizing pollution of water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.