One of the main resources that the pharmaceutical industry uses is water. Facilities for manufacturing pharmaceutical and healthcare products must be of the highest caliber. To ensure that the water utilized is of the required standard of purified water, more care and attention must be given.

Since pharmaceutical applications are extremely complex and necessary for producing the medications that save millions and millions of lives worldwide, pharmaceutical water treatment is necessary.

Why is RO needed for pharmaceutical industry?

RO (Reverse Osmosis) is needed in the pharmaceutical industry for water purification. Water is used in various stages of drug manufacturing, and it must meet specific quality standards to avoid contamination and ensure that the drugs produced are safe and effective.

RO is an effective water purification technology that removes a wide range of contaminants, including bacteria, viruses, dissolved salts, organic matter, and other impurities, which may be present in raw water. RO can reduce the total dissolved solids (TDS) and conductivity levels of water, making it suitable for use in various pharmaceutical applications such as cleaning, formulation, and manufacturing.

Furthermore, RO water is free from minerals, ions, and other impurities, which can cause scaling, corrosion, and damage to pharmaceutical equipment. The use of RO water reduces the risk of product contamination, which can affect the quality and safety of pharmaceutical products.

What is the use of commercial RO Filter for pharmaceutical industry?

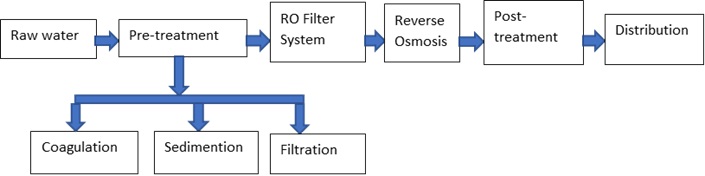

RO (Reverse Osmosis) filter systems are widely used in the pharmaceutical industry to purify water, which is used in various stages of drug manufacturing. The use of RO filter systems ensures that the water meets the required quality standards and is free from impurities. Here is a flowchart that outlines the use of commercial RO filter systems in the pharmaceutical industry:

1. Raw Water Source: The first step is to identify the raw water source, which can be either surface water or groundwater.

2. Pre-Treatment: The raw water undergoes pre-treatment to remove large particles, debris, and organic matter. This can be achieved through various methods such as coagulation, flocculation, sedimentation, and filtration.

3. RO Filter System: The pre-treated water then enters the commercial RO filter system. The RO filter system consists of several components, including the membrane, pressure vessel, pumps, and control panel.

4. Reverse Osmosis: The water is forced through the RO membrane, which acts as a barrier, allowing only pure water molecules to pass through. The impurities and contaminants are left behind and are discharged as reject water.

5. Post-Treatment: The purified water then undergoes post-treatment, which involves the addition of disinfectants such as chlorine or UV irradiation to ensure that the water is free from any remaining bacteria or viruses.

6. Storage: The purified water is then stored in a tank, which is typically made of stainless steel, to maintain its purity and prevent contamination.

7. Distribution: The purified water is distributed to various points of use within the pharmaceutical facility, such as laboratories, production areas, and cleanrooms.

8. Quality Control: The purified water is subject to rigorous quality control testing, which involves various parameters such as pH, conductivity, total organic carbon, and endotoxin levels, to ensure that it meets the required quality standards.

9. Maintenance: Regular maintenance of the RO filter system is essential to ensure that it operates at peak efficiency and maintains the required quality standards.

Conclusion:

To assure the creation of high-quality medicines, commercial RO filter systems are essential in the pharmaceutical business. The above flowchart outlines the various steps involved in the use of RO filter systems in the pharmaceutical industry. The risk of product contamination, which can impact the quality and safety of pharmaceutical products, is decreased by using RO filter systems.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com