How do extended aeration systems work?

Advanced aeration systems work by providing ideal conditions for aerobic bacteria and other microorganisms. These microorganisms break down the biological pollutants contained in raw sewage. The sewage treatment plant provides the proper environment, sufficient oxygen, and other elements to allow bacteria to consume organic matter and grow alive in the sewage treatment plant. In this way, aerobic bacteria and microorganisms break down wastewater and waste into a stable form-odourless and chaotic. The aeration chamber is an important part where 90% of the processing takes place.

How does the process work?

This process works according to the following theory.

>Waste in domestic wastewater is usually organic (biodegradable). That is, aerobic microorganisms can use organic materials as a food source in the presence of oxygen. In nature, when waste is dumped into an untreated stream, the stream's bacteria can break down the wastewater, deplete the dissolved oxygen content, and kill all aquatic life in the stream.

>Like nature, advanced aeration systems blow in air (29% oxygen), grow bacteria that eat sewage coming from businesses and homes. Bacteria in the aeration tank break down the wastewater into floating sludge. The liquid in the aeration chamber, called the mixture, has a light milkshake and brown consistency, similar to coffee with cream. However, keep in mind that different systems have different colours depending on the type of waste.

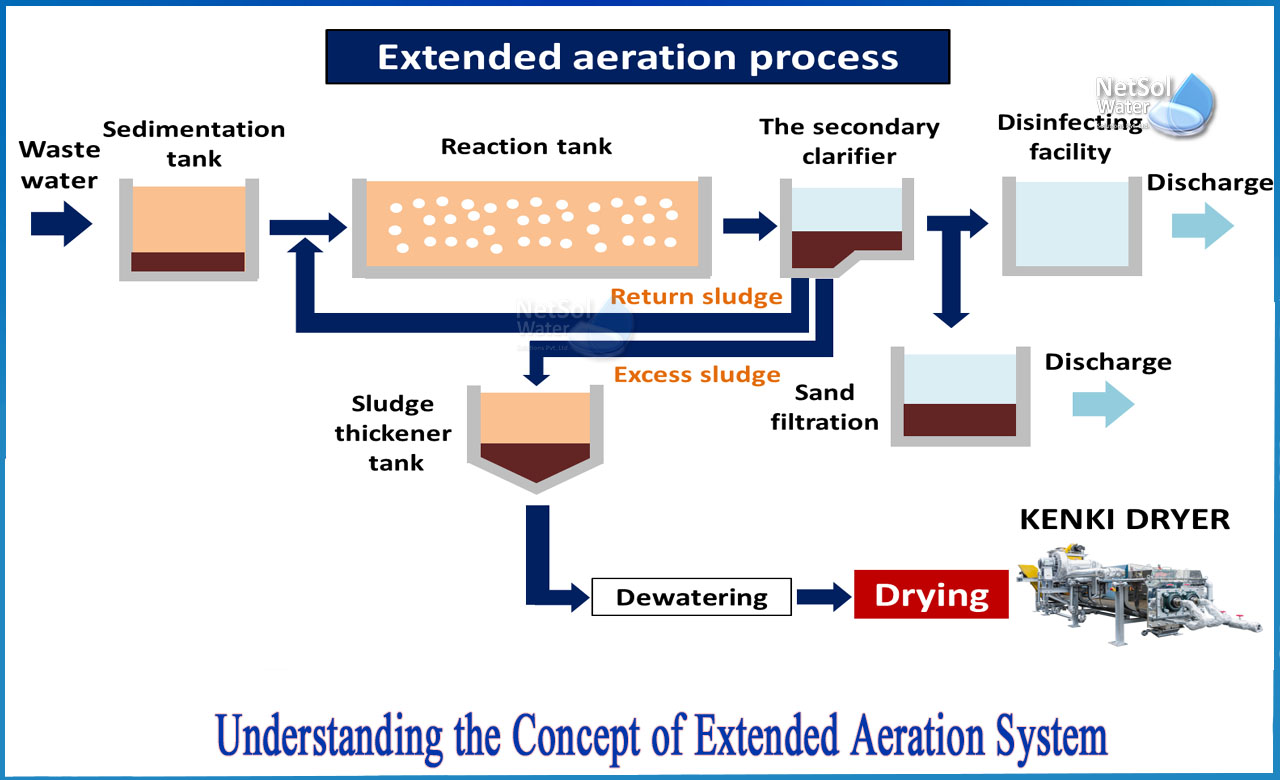

>A settling tank (purification device) is placed behind the aeration chamber so that the microorganisms that have grown in the aeration chamber settle by gravity and form sludge at the bottom of the septic tank. Most microorganisms settle to the bottom of the settling chamber, where they are pumped back to the head of the aeration chamber. The microorganisms then initiate a cycle of food intake through the organic matter that arrives in the wastewater. This material is known as Return Sludge (RAS).

>The clear liquid (85-90% treated) at the top of the settling chamber usually flows to a metering pump station/slow sand filter or polishing pond for further treatment (95%). The treated waste is then disinfected with chlorine and the chlorine is removed by a de-chlorinator. Currently, some facilities are replacing chlorine disinfection/de-chlorination equipment with UV disinfection. Disinfection is the process of killing pathogenic microorganisms. The final emission is usually a flow of dilution sufficient to safely absorb the remaining 5% of contaminants without causing measurable harm to the environment.

How does it affect if not maintained properly?

Poor operation and maintenance usually lead to serious environmental and health problems. Your hygiene is not a magical device. It requires inspection and proper care and maintenance to function effectively, like your car or home. Proper installation and maintenance of wastewater treatment and disposal systems is essential to the protection of our water resources.

Some of the packed sewage treatment facility is used to bridge the gap between individual sewage treatment facilities and large communal facilities. They are used to purify wastewater from settlements, mobile home parks, schools, amusement parks, elderly housing, factories, and other commercial activities in surrounding areas without sewerage in municipalities.

Conclusion

In theory, an advanced aeration process uses air to consume organic compounds and purify wastewater by oxidizing volatiles (both solid and liquid) to inert gases, water, and sludge.Continuous aeration of these concentrated solids produces organisms and grows in colonies. Colonies attach to volatile substances and break them down into water, carbon dioxide, and ash. The result is clear, odourless wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.