How many types of Sewage pumps?

Netsol Water collaborates with a wide range of international organizations to tackle complicated problems of STPs by strategically integrating modern treatment technology with practical solutions.

In this blog, we will talk about sewage pumps.

Pumps of the following categories are used to pump sewage:

1. Centrifugal Pumps;

2. Pumps with a Reciprocating Action;

3. Pneumatic Ejectors or Air Pressure Pumps.

What are Centrifugal pumps?

These are the most widely used for pumping sewage because they are easy to install in pits and sumps, and they can readily transfer the suspended materials contained in the sewage. The impeller of a centrifugal pump is a spinning wheel housed in an airtight casing to which the suction pipe and delivery pipe or rising main are attached.A pump is a simple but essential mechanical device that provides the force needed to move fluid at a set rate.

The efficacy of any equipment that accomplishes work (transfers energy across a distance) is measured in power. Despite the fact that watts and kilowatts are more widely used units of power measurement, horsepower is still widely utilized.

What are Reciprocating Pumps?

Due to their high initial cost, difficulty in maintenance, and increased valve wear and tear, reciprocating pumps are used much less for sewage pumping these days. However, reciprocating pumps may be utilized after passing the sewage through a screen with a 20 mm spacing in circumstances where tough sludges must be dealt with and huge amounts of sewage must be pushed against low heads.

There are two types of reciprocating pumps:

(1) Type of Ram, and

(2) Type of propeller.

A: A piston or plunger passes through glands in a ram type reciprocating pump, displacing liquid in a vessel. The piston or plunger is not placed in the cylinder to fit snugly. The diaphragm pump is an example of a regularly used ram type reciprocating pump.

B: A multiple blade screw rotor or propeller travels vertically inside a pump casing, causing the sewage to be elevated in the propeller type reciprocating pumps. It uses inlet guide vanes to draw liquid in and output guide vanes to discharge it. As a result, its movement is comparable to that of a ship's propeller. The axial-flow screw pump is an example of a reciprocating pump with a propeller.

What are Pneumatic ejectors?

These are also known as air pressure pumps or pneumatic ejectors. These are used to pump or lift tiny amounts of sewage.

The following are favorable circumstances for installing pneumatic ejectors:

(i): When little amount of sewage needs to be moved from a building's cellar or basement to a high-level sewer;

(ii): When the volume of sewage from a low-lying region is insufficient to warrant the installation of a pumping station; and

(iii): Where a small-capacity centrifugal pump is liable to clog.

Compressed air is used in pneumatic ejectors to remove sewage.

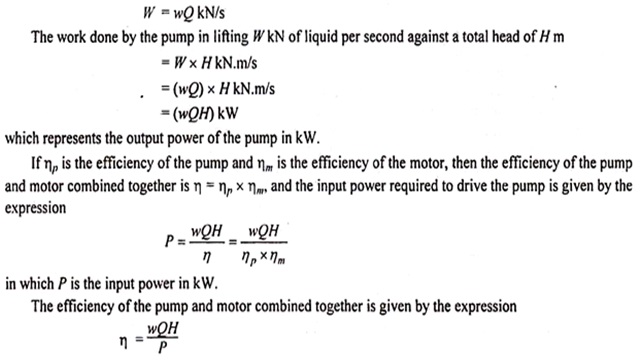

Pump Power and Efficiency

If ‘Q’ is the pump discharge (or the rate at which the pump lifts liquid) in m3/s (or cumec), and ‘w’ is the specific weight of liquid in kN/m3,

Weight of the liquid ‘W’, lifted by the pump per second is given by the expression:

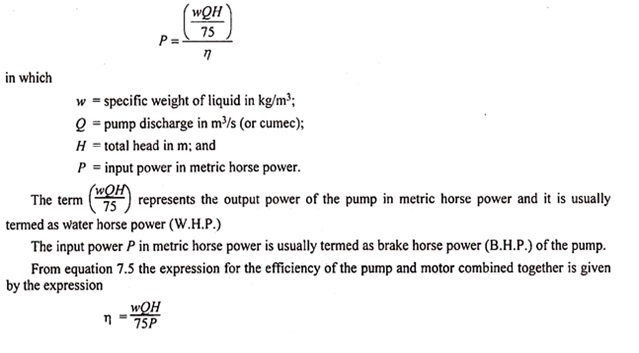

In metric units the input power required to drive the pump is given by the expression:

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.