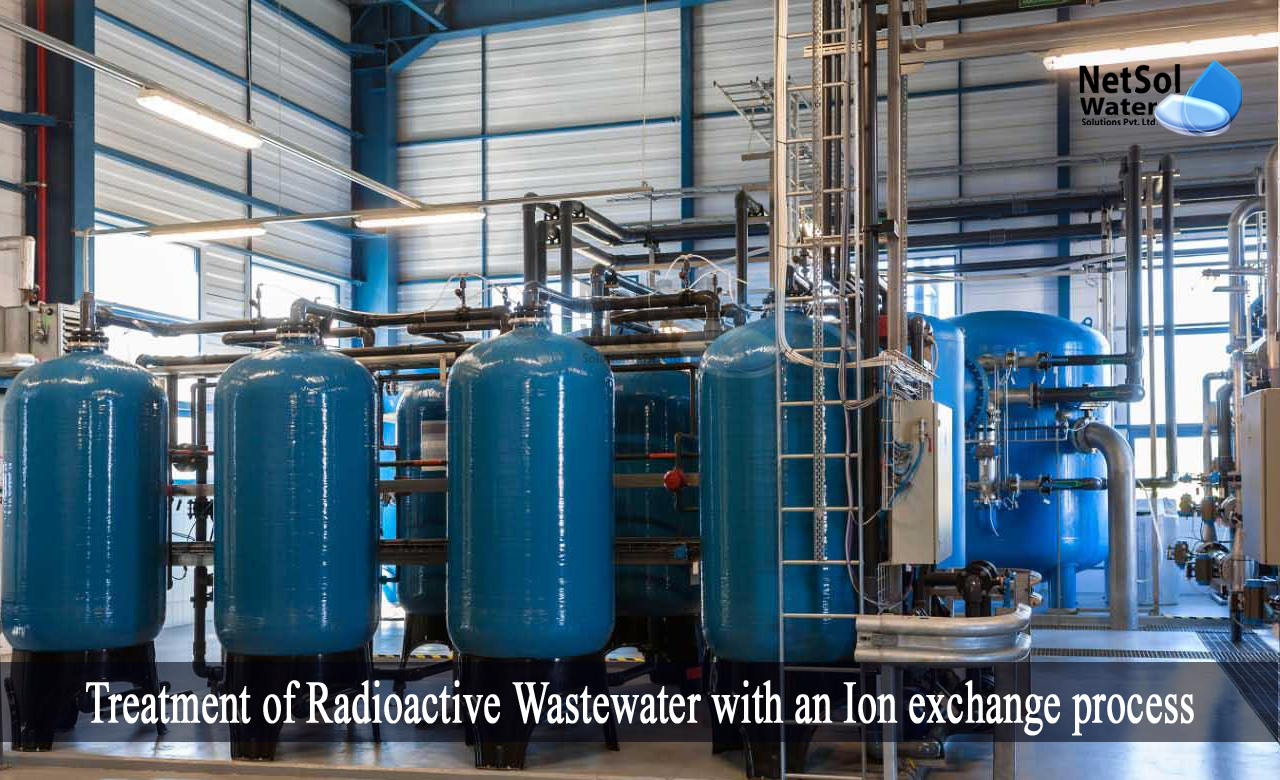

How to treat Radioactive Wastewater with an Ion exchange process?

Nuclear technology necessitates a number of effluent streams’ treatment activities, such as the removal of radioactive contaminants, and the balancing of water chemistry, before it can be released back into the ecosystem. Nuclear fuel reprocessing plants, nuclear power plants, and nuclear technology research institutes, are significant sources of radioactive contamination. Water treatment technologies, like ion-exchange, might be used to treat radioactive wastewater, reactor main coolants, spent fuel pools, or liquid radioactive waste.

As we know now that ion exchange is a potential approach. It is a well-developed practice that has been utilized for many years, in both the nuclear sector and other businesses.

Effect of radioactive wastewater on human health

Radioactive wastewater has created serious concerns about human health and the environment, as the use of radioisotopes in numerous industrial sectors has increased. High-energy particles or electromagnetic waves are assumed to be emitted by all radionuclides, and exposure to such radiation can cause chemical bonds to break, and proteins in human cells to ionize. As a result, radioactive wastewater treatment is inextricably linked to human health.

Radioactive Wastewater Classification

|

Class |

Characteristics |

|

EW |

Activity levels at or below clearance thresholds, based on a public exposure of less than 0.01 mSv |

|

LILW |

Thermal power less than 2 kW/m3 and activity levels greater than clearance levels |

|

LILW-SL |

Long-lived radioactive concentrations are limited (4,000 Bq/g in individual waste packages and 400 Bq/g on average per package for long-lived alpha-emitting radionuclides). |

|

LILW-LL |

Long-lived radioactive concentrations surpass those permitted for short-lived waste |

|

HLW |

Thermal power more than 2 kW/m3 and radioactive levels that exceed short-term waste restrictions |

Use of resins to treat radioactive wastewater

Organic ion exchange resins have traditionally been used to regulate system chemistry, decrease corrosion and degradation of system components, and remove radioactive contaminants, in nuclear power plant process water systems. Organic resins are also used in chemical decontamination and cleaning processes, such as reagent regeneration and radionuclide removal.

Ion exchange is a very effective method of transferring radioactivity, from a large volume of liquid to a small amount of solid. The management of spent ion exchange media must be considered, in the context of an integrated waste management system for all radioactive waste produced.

Ion Exchange technique for Radioactive Effluent Treatment

Ion exchange is the process of exchanging mobile ions from an external solution for ions,which are electrostatically bonded to the functional groups, in a solid matrix. Cations are exchanged when the functional groups are negatively charged, while anions are transferred when they are positively charged.

The separation of these species can be accomplished by taking advantage of the fact that under certain conditions, ion exchange media have a greater affinity for certain ionic species than for others; for example, the hydrogen form of a cation exchanger will release its hydrogen ion into solution, and pick up a cesium ion from the solution, according to the equation:

![]() R - H + Cs+R - Cs + H+

R - H + Cs+R - Cs + H+

Where, R denotes the ion exchange resin's insoluble matrix,because every cesium ion taken from the solution is replaced by a hydrogen ion.

Factors influencing ion-exchange capacity

1. Temperature

2. Ionic dimension

3. Valency

4. Concentration of solution

5. Degree of cross-linking

6. Functional group type

Application of ion exchange process

• Primary coolant purification (water)

• Primary sewage treatment

• Water treatment from the fuel storage ponds

• Steam generator blow-down demineralization

• Liquid waste and drainage water treatment

• Purification of recycled boric acid

• The condensate polishing, with boiling water reactors.

Advantagesof ion-exchange process for treating radioactive wastewater

· Simple to use

· High efficiency

· Clean

· Cost-effective

· Easy and convenient

Consideration for Cost

Before implementing a certain ion exchange treatment process, a thorough economic analysis should be conducted. The key cost components to consider are as follows:

· Capital outlays

· The initial cost of the ion exchange medium

· The running costs

· The costs of treating and disposing of a used ion exchanger

Best Manufacturers of Water Softener Plants

Netsol Water, based in Greater Noida, India, is a well-known manufacturer of water and wastewater treatment systems. We are well-known for being the top commercial RO plant manufacturers, industrial RO plant manufacturers, ZLD Plant Manufacturer, sewage treatment plant manufacturers, Water Softener Plant Manufacturers, effluent treatment plant manufacturers, and much more.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.