How to treat of Industrial Wastewater?

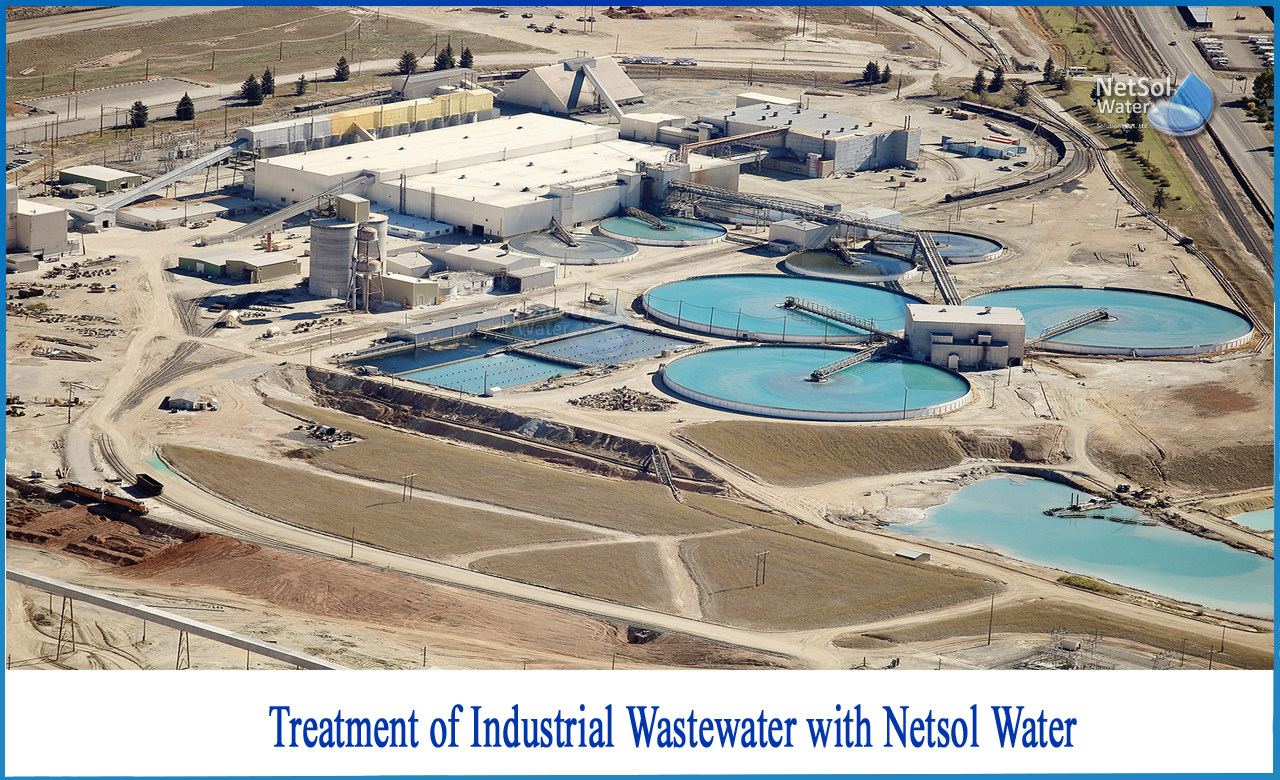

Industrial wastewater treatment includes the mechanisms and processes used to treat water that is somehow contaminated by artificial industrial or commercial activities before it is released or reused into the environment.

Most industries produce wet waste, but a recent trend in developed countries is to minimize this production or to recycle such waste within the production process. However, many industries still rely on the process of producing wastewater.

Some of the industrial wastewater sources

· Agricultural waste

· Brewery

· Dairy

· Pulp and paper industry

· Steel industry

1: Brewery

Beer is a low-alcohol fermented beverage made from a variety of grains. Barley is the mainstreamcereal, but wheat, corn and other grains can be used.

Untreated wastewater typically has suspended solids in the range of 10-60 milligrams (mg/l), biochemical oxygen demand (BOD) in the range of 1,000-1500 mg/l, and COD ranges around 1,800-3,000 mg/l, Nitrogen is in the range of 30-100 mg/L. Phosphorus may be present in concentrations on the order of 10-30 mg/l. Wastewater from individual process steps varies. For example, bottle cleaning produces a large amount of wastewater, but contains only a small portion of the total organic matter discharged from the brewery.

Fermentation effluent andFiltration effluents are high in organic matter and BOD, accounting for about 3% of total wastewater and 97% of total BOD. The pH of the effluent is about 7 on average for the combined effluent, but can vary from 3 to 12 depending on the use of acidic and alkaline detergents. The average drainage temperature is about 30 ° C.

2: Dairy

The dairy industry involves processing raw milk into products such as milk powder, butter, cheese, yogurt, condensed milkand ice cream using processes such as cooling, cryo-sterilization, and homogenization. Typical by-products are buttermilk, whey, and their derivatives.

Dairy wastewater contains dissolved sugars, proteins, fats and, in some cases, residues of additives. The most important parameter is the biochemical oxygen demand (BOD), which averages 0.8-2.5 kilograms (kg/t) per ton of milk in untreated wastewater. Chemical oxygen demand (COD),it is usually about 1.5 times the BOD level, 100-1,000 milligrams/l total suspended solids.

The production of whipped cream, butter, cheese and whey is the main source of BOD in wastewater. The waste load equivalent to a particular milk component is:

1 kg of milk fat = 3 kg of COD;

1 kg of lactose = 1.13 kg of COD; and,

1 kg of protein = 1.36 kg of COD.

Wastewater can contain contaminated materials or pathogens from the manufacturing process. Dairy products often generate odours and, in some cases, dust, that must be controlled. Most solid waste can be processed into other products and by-products.

3: Pulp and paper industry

The pulp and paper industry is one of the oldest and most important industries in the world. The socio-economic importance of paper is directly related to the country's industrial and economic growth, so it has unique value for the country's development.

The pulp and paper factory is a major industry that uses large amounts of lingo-cellulosic materials and water in its manufacturing process and releases chlorinated lignin, sulfonic acid, chlorinated resin acid, chlorinated phenol, and chlorinated hydrocarbons into wastewater. Approximately 500 types of chlorinated organic compounds have been identified, including chloroform, chlorates, resin acids, chlorinated hydrocarbons, phenols, catechols, guaiacol, furan, dioxin, syringol, and vanillin. These compounds are produced by the reaction of residual lignin from wood fibre with the chlorine/chlorine compounds used for bleaching.

Coloured compounds and adsorptive organic halides (AOXs) released to the environment by pulp and paper mills cause many problems. Wood digestion and paper product production discharge biochemical oxygen demand (BOD), chemical oxygen demand (COD), suspended solids (SS), and untreated or poorly treated wastewater into the body. This wastewater is toxic to aquatic organisms and has strong mutagenic effects and physiological disorders.

4: Steel industry

Extracting iron from ore requires a strong reduction reaction in a blast furnace. Cooling water is inevitably contaminated with products, especially ammonia and cyanide. To produce coke from coal in a coking plant, water must also be used for water cooling and separation of by-products. Waste flow contamination includes gasification products such as benzene, naphthalene, anthracene, cyanide, ammonia, phenol, and cresol, as well as many more complex organic compounds collectively referred to as polycyclic aromatic hydrocarbons (PAHs).

Converting iron or steel to a sheet, wire, or rod requires high and low temperature mechanical conversion steps. Water is often used as a lubricant and coolant in this step. Pollutants include hydraulic oils, sebum and particulate matter. The final treatment of steel products before resale for manufacture is a strong mineral acid to remove rust and prepare the surface for tin plating or chrome plating, or other surface treatments such as electroplating and painting.