Overview

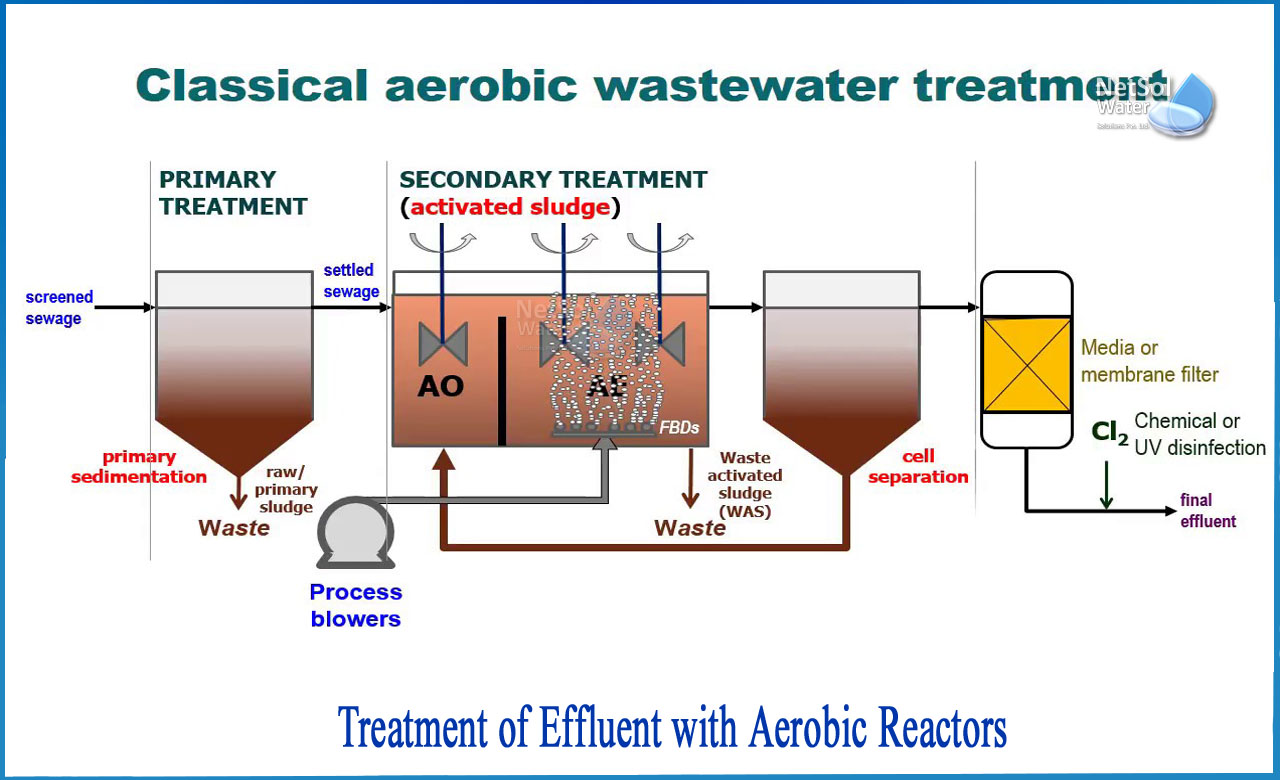

A wastewater treatment plant typically uses three methods to treat wastewater: primary, secondary, and tertiary, which use physical, biological, and chemical processes, respectively. The biological treatment process is critical in the breakdown of organic waste generated by households and various industries. Aerobic biological treatment and anaerobic biological treatment of effluent are the two main types of biological wastewater treatment.

What is aerobic treatment process in wastewater treatment?

Aerobic wastewater treatment is a biological process that uses oxygen to break down organic contaminants as well as other pollutants such as nitrogen and phosphorous. A mechanical aeration device, such as an air blower or compressor, continuously mixes oxygen into the wastewater or sewage. Aerobic microorganisms feed on the organic matter in the wastewater, converting it to carbon dioxide and biomass that can be removed.

Aerobic treatment is typically used to polish industrial wastewater that has already been treated anaerobically. This ensures that the wastewater has been completely degraded and can be safely discharged in accordance with stringent environmental regulations. Aerobic treatment processes are appropriate for a variety of industries, including food and beverage, chemical, and municipal.

What are some of the advantages of aerobic wastewater treatment systems?

Aerobic wastewater treatment is a stable, simple, and efficient process that yields high-quality secondary effluent. The resulting sludge is odorless and can be sold as high-quality agricultural fertilizer.

Aerobic treatment systems, when combined with anaerobic treatment, ensure complete contaminant and nutrient removal. This means that your wastewater can be discharged safely without violating stringent environmental regulations.

What are the different types of aerobic wastewater treatment systems?

In wastewater treatment plants, various aerobic biological treatment systems are used-

1: Typical Activated Sludge

The traditional activated sludge process is the most widely used aerobic biological treatment method in aerobic reactors(also known as bioreactors). It is widely used to treat industrial effluents and has undergone numerous changes since its inception.

An aerobic reactor, which is essentially a stirred tank seeded with a portion of recycled activated sludge containing microbes, is used in this process. Because an aerobic reactor has a large volume, air compressors are used to supply a sufficient amount of oxygen into the system so that microbes can perform their function with dissolved oxygen.

Nitrification and de-nitrification can be carried out in an aerobic tank and a bioreactor, in addition to producing carbon dioxide and water as byproducts of the aerobic process.

2: MBBR

The key component of Moving Biofilm Bed Reactors – MBBRs is aeration tanks filled with biofilm carriers. Plastic biofilm carriers of various shapes and sizes are suspended inside the aerobicreactor using aeration devices. It allows for the treatment of high BOD wastewater in a smaller area. Furthermore, there is no sludge recycling.

3: MBR

Membrane Bioreactors are advanced aerobic biological treatment systems that combine elements of the activated sludge process with membrane filtration. It aids in the separation and recycling of suspended solids without the use of traditional sedimentation methods. As a result, MBRs produce high-quality effluent by concentrating BOD. Although the initial investment and ongoing maintenance costs are high, the efficiency is unrivalled.Advanced microbial strains have emerged as a promising solution for improving the performance of the aerobic wastewater treatment process using aerobic reactors.

Netsol Water is an example of a cutting-edge solution. The unique microbe consortium aids in the degradation of organic matter in wastewater, reduces sludge volume, controls bad odor, and improves the treatment facility's performance. Contact us today for more information.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.