How to Treat and Reuse of Wastewater from the Essential oil Industry?

The Fragrances and Essential Oils industry can be classified as a subset of the cosmetics industry, although it has distinct features. Solvents, alcohols, and Essential Oils are the most often utilized compounds in this business.

Given the rapid development in demand for perfumery goods, it is critical to include this business, as well as its consequences on the environment, among the current major environmental pollution issues.

Because of the unique characteristics of wastewater and the type of pollutant generated by the Fragrances and Essential Oils industry, if this water were discharged into the sanitation system, the municipal plant would quickly become saturated, so a decentralized treatment is more appropriate, both to treat the water and to allow its immediate reuse.

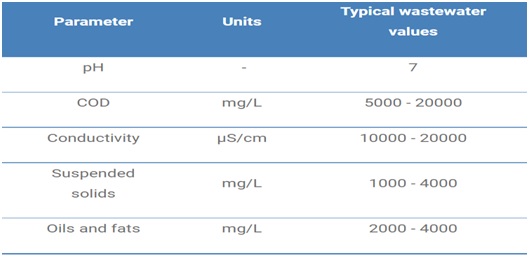

Characteristics of Wastewater generated from the Fragrance and Essential oil Industry

The steam distillation process necessitates a large amount of water and, as a result, produces a lot of wastewater. Wastewater is the portion of the hydrolate that remains after the extraction of the aromatic essences.

It is mostly made up of:

1: Starch.

2: Salts.

3: Fatty acids.

4: Esters, ketones, ethers, aldehydes, alcohols and alkenes.

This means that wastewater from the Fragrances and Essential Oils industry is characterized by a high content of organic load (plant remains, starch, and organic structures with closed ring and double bonds, which implies great difficulty for biological degradation and emphasises its refractory character), conductivity (due to high salt concentrations), and oils and fats from a physical-chemical standpoint.

Typical characterization of wastewater from the Fragrances and Essential Oils industry is shown in table below:

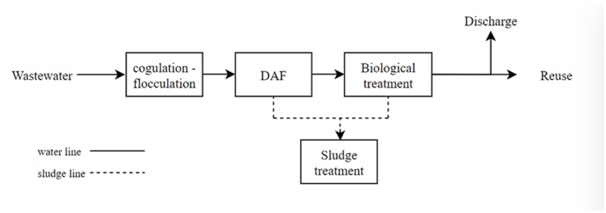

Wastewater treatment and reusefrom the Fragrance and Essential oil Industry

Below is a description of the technique that has shown to be the most effective in creating very high quality treated effluents thus far. The high difficulty of biologically eliminating the organic load precludes the use of traditional technologies such as bioreactors, and instead necessitates the use of a highly effective pre-treatment for the removal of part of the organic matter and its transformation into easily separable compounds, as well as the removal of oils and fats.

Pre-treatment process and biological treatment effectively applied in wastewater from the Fragrances and Essential Oils industry is shown in the form of flowchart

Pre-treatment in the Fragrance and Essential oil Industry

Coagulation, flocculation, and pH correction, followed by a clarifying step, is a common and successful physicochemical treatment sequence. Dissolved air flotation, or DAF, is a very efficient method for this clarifying step. Coagulation's goal is to destabilise colloidal matter. The reaction is triggered by the addition of a coagulant, such as iron salts, poly aluminium chloride, organic coagulants, and so on. The purpose of neutralization is to change the pH of a solution by adding bases or acids. Flocculation is the addition of a polyelectrolyte with a defined polarity for each individual situation (anionic, cationic, or non-ionic) meant to add the clots created in the preceding procedure in order to have flocs of sufficient size for the separation of water from them (clarification).

Compressed air is supplied into a recirculating clarifying stream during DAF treatment, dissolves in the liquid medium, and then produces 30 to 50 m bubbles when discharged via a dispersion head into the flotation chamber. The coagulated and flocculated particles cling to the bubbles and float to the DAF unit's top, where they are mechanically removed.

The settleable stuff falls into the sediment compartment at the bottom of the DAF unit, where it is extracted by a sludge extraction system, which is commonly worm gear.The cleared water exits the DAF unit via a supernatant system that may be adjusted. The recirculation pump will reroute a portion of this purified water stream into the compression and air saturation system.

When properly designed, the coagulation-flocculation sequence followed by DAF is a very common and widely used concept in the treatment of wastewater from the Fragrances and Essential Oils industry, and it has proven to be efficient in terms of performance and costs, both operational and chemical and energy consumption. It is a reliable and effective pre-treatment for the treatment of typical industrial wastewater.

Biological treatment in the Fragrance and Essential oil Industry

The primary goal of a biological process is to eliminate the residual water's organic load through the action of microorganisms in biological reactors. Traditional activated sludge reactors with anoxic and aerobic zones are commonly employed to perform nutrient removal, but membrane bioreactors, or MBRs, are a more efficient biological system. Very clean, high-quality water is obtained at the MBR biological reactor's outflow, which may be reused as service or process water.

MBR reactors combine biological treatment with membrane technology as a water and sludge separation method. Biological procedures can be aerobic, anoxic, or anaerobic; an aerobic treatment is typically used to treat wastewater from the Fragrances and Essential Oils business.

Conclusion

The removal of organic load, salts, fats and oils, is the primary goal when building a wastewater treatment process for the Fragrances and Essential Oils sector.

However, because this business has such a high need for water, the tendency is to not only cure it, but to polish it so that it may be reused. As a result, choosing the right technologies from Netsol, to use is crucial in the development of a plant.

What can we offer?

Netsol Water, is a well-known water and wastewater management company based in Greater Noida, India. We offer a variety of water and wastewater treatment services throughout India, utilizing the most up-to-date equipment and advanced technologies.

We provide innovative RO Plant services, Water Softeners, sewage treatment plant design, effluent recycling treatment, and a variety of other services. Our water and wastewater treatment systems are highly effective at removing a wide range of chemical, physical pollutants, and biological contaminants.

Call us on +91 9650608473